Method for removing metals from waste water and apparatus for removing metals from waste water

A metal and electrolysis device technology, applied in chemical instruments and methods, gaseous effluent wastewater treatment, water pollutants, etc., to achieve the effect of cheap removal and reduction of metal concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

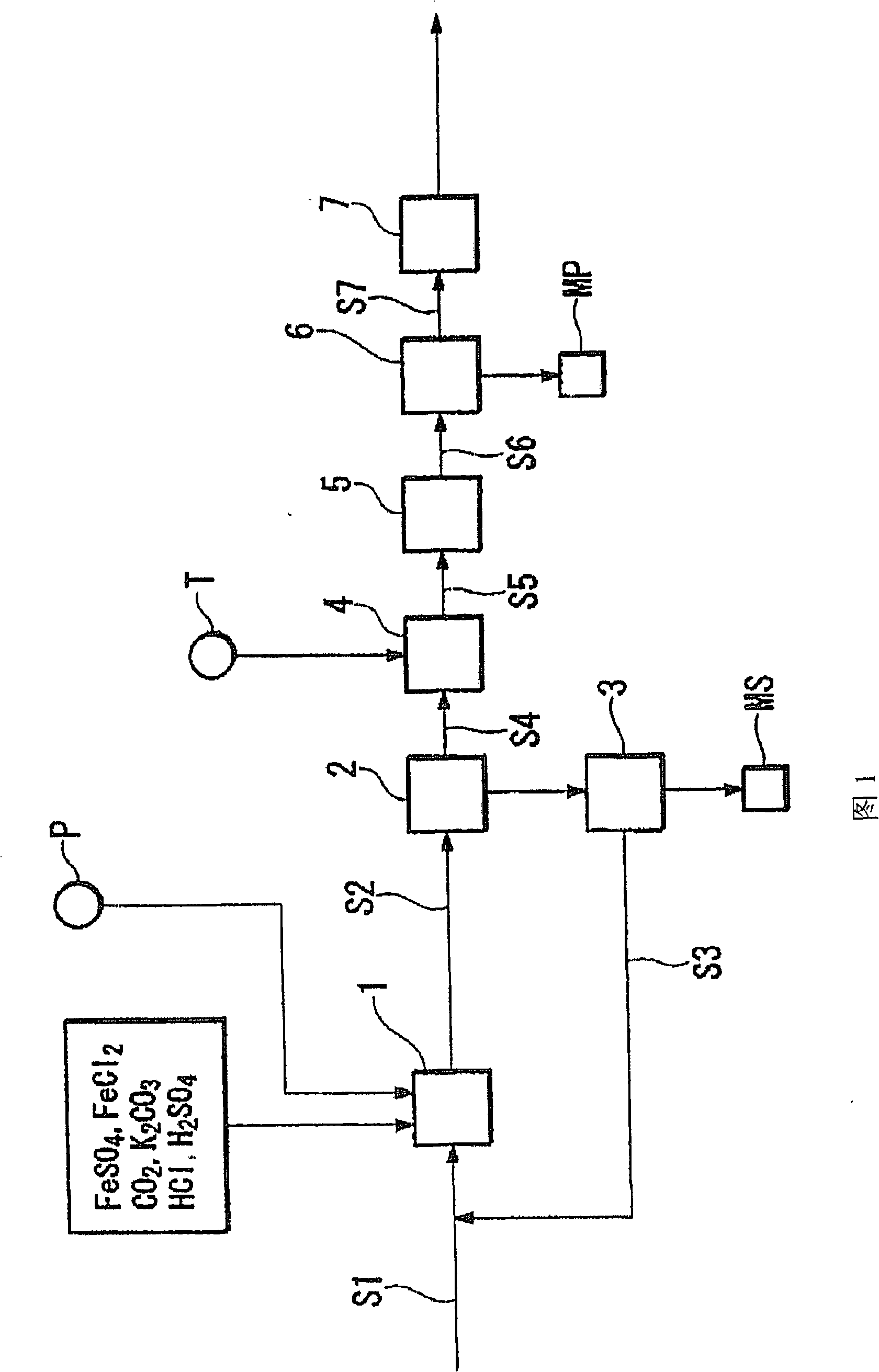

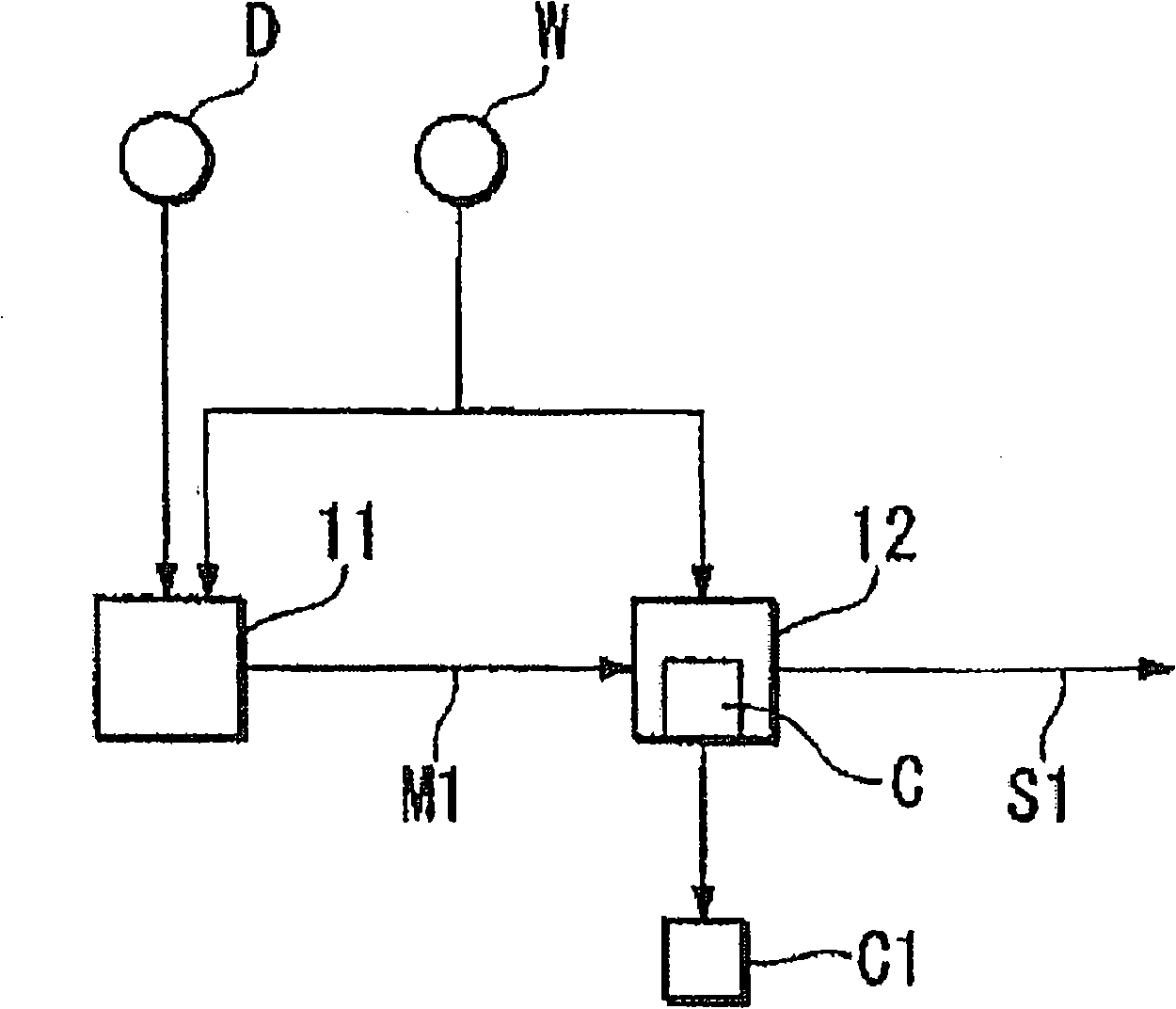

Method used

Image

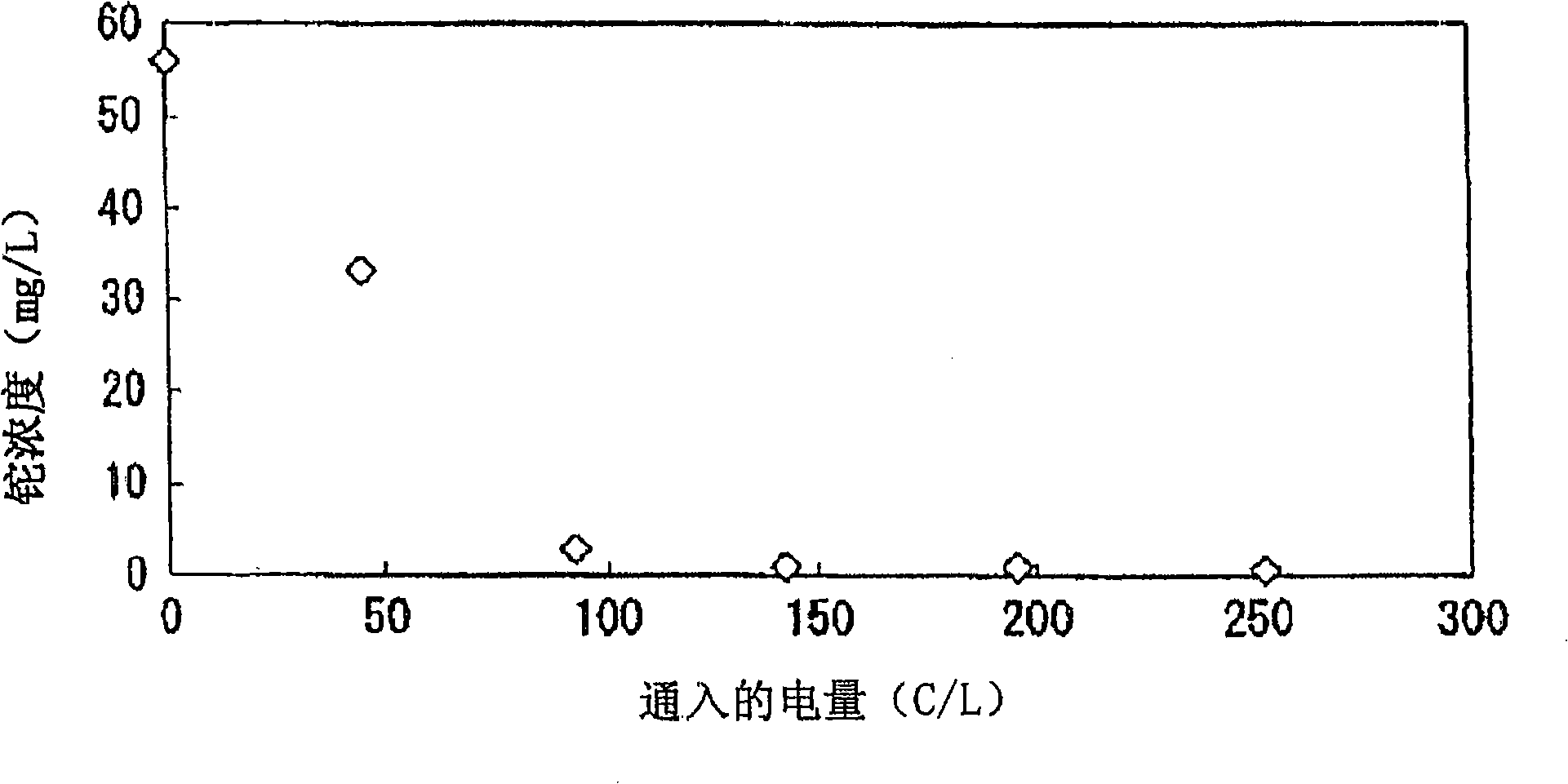

Examples

Embodiment

[0104] The following examples are given to illustrate the method and device for removing metals from wastewater according to the present invention, but are not limited to the following examples at all.

[0105] In this example, as the waste water to be treated, the waste water that washed the chlorine bypass powder discharged from the chlorine bypass device installed in the cement manufacturing facility with water to elute metal components was used.

[0106] Table 1 shows the composition of this chlorine bypass powder.

[0107] project

unit

content

SiO 2

weight%

8.1

Al 2 o 3

weight%

2.5

Fe 2 o 2

weight%

0.8

CaO

weight%

30.9

MgO

weight%

0.7

SO 3

weight%

4.6

Na 2 o

weight%

1.6

K 2 o

weight%

25.7

Cl

weight%

20.8

Cu

mg / Kg

1.750

Zn

mg / Kg

813

As

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com