Pile-formation sunken tube of pedestal pile

A technology of expanding bottom piles and prefabricated steel, which is applied in sheet pile walls, buildings, infrastructure projects, etc., can solve problems such as inability to carry out bottom expansion work, affecting the smooth passage of the pile body, and increasing the inner diameter of the bottom of the immersed tube. The effect of implementation, easy slotting, reduction of processing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

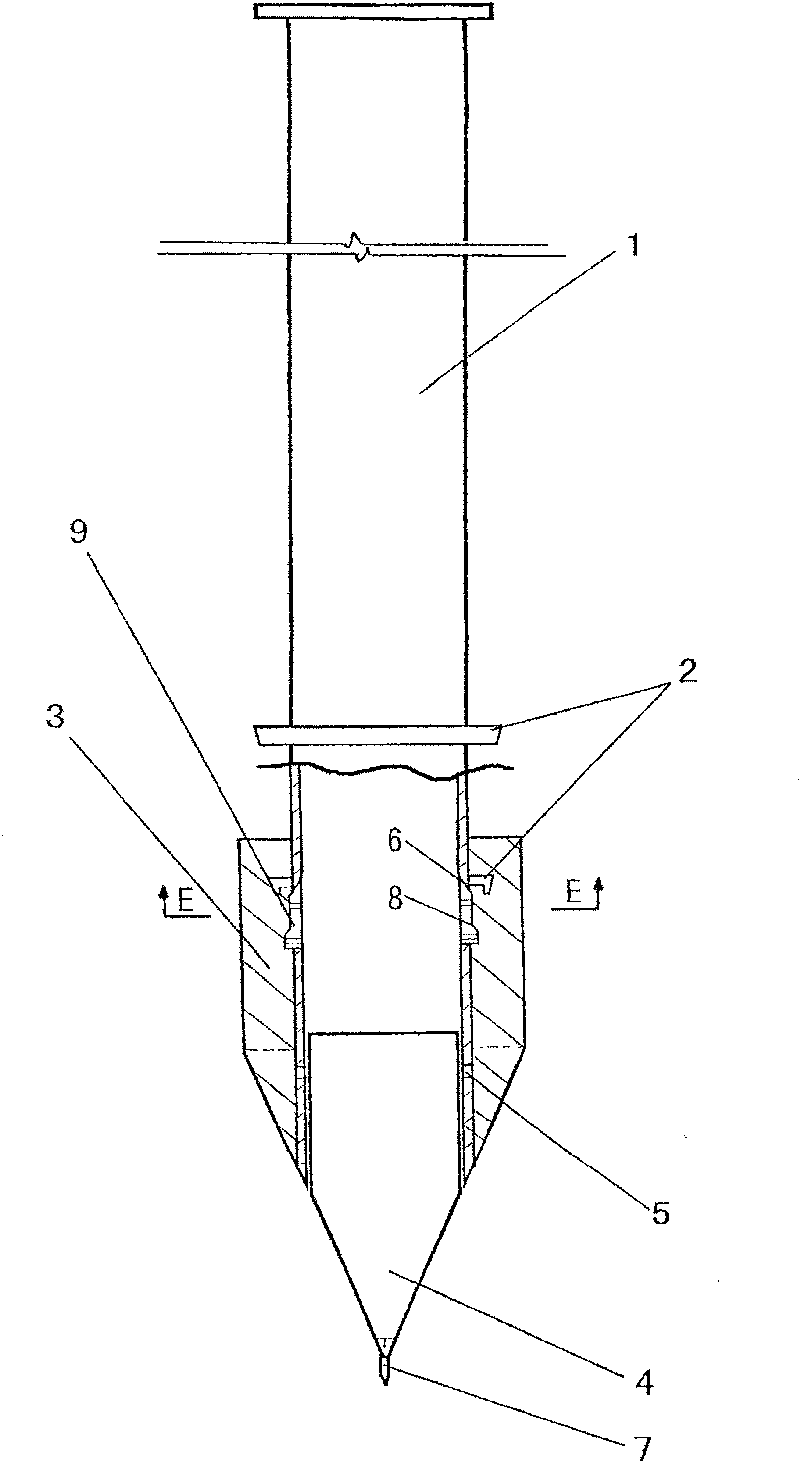

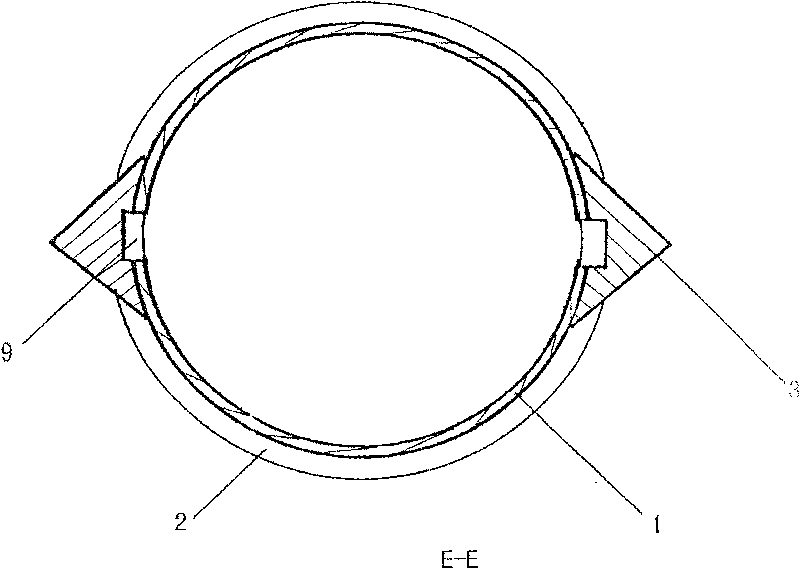

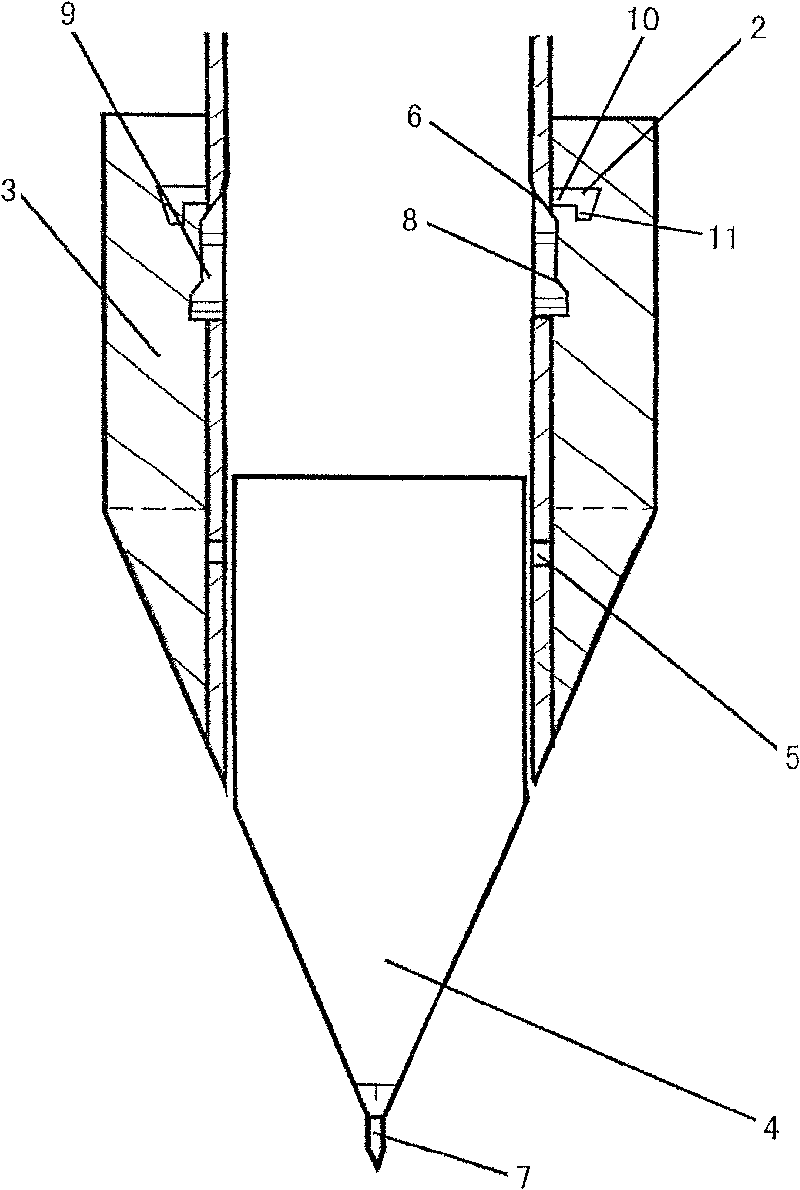

[0020] Such as figure 1 , figure 2 with image 3 As shown, the outer wall of the bottom connected to the pipe body 1 is provided with at least two guide wings 3 evenly distributed in the circumferential direction, and the inner side of the bottom is provided with positioning iron feet matching the existing excavating equipment positioning iron feet at the position corresponding to the guide wings 3 Slot 9, the upper port of the tube body 1 is provided with positioning marks along the circumferential direction at the position corresponding to the bottom inner positioning groove 9. In order to facilitate the positioning of the iron feet into the positioning groove 9, the upper longitudinal section of the positioning groove 9 is a wedge-shaped slope, and the lower part In line with the outer end of the positioning iron foot, the positioning groove 9 has two inclined surfaces, namely the upper inclined surface 6 and the lower inclined surface 8 of the positioning groove. The purpose...

Embodiment 2

[0022] The sealing ring 2 described in the first embodiment, such as Figure 4 The following structure can be adopted as shown: it is composed of a metal ring body 10 and a rubber ring 12 arranged at the lower end of the metal ring body 10, the diameter of the rubber ring 12 is smaller than the diameter of the metal ring body 10, and the other structures are the same as the first embodiment.

Embodiment 3

[0024] The sealing ring 2 described in the first embodiment, such as Figure 5 The following structure can be adopted as shown: it is composed of a metal ring body 10 and a ring of flange 11 provided at the upper end thereof. The longitudinal section of the metal ring body 10 and the metal ring body 10 is large and small with a certain taper. The other structure is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com