Pile-formation sunken tube

An immersed tube and pile-forming technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of affecting the smooth passage of the pile body, increasing the inner diameter of the bottom of the immersed tube, and unable to carry out the bottom expansion work, and achieving easy implementation. , Reduce the difficulty and cost of processing, the effect of easy slotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

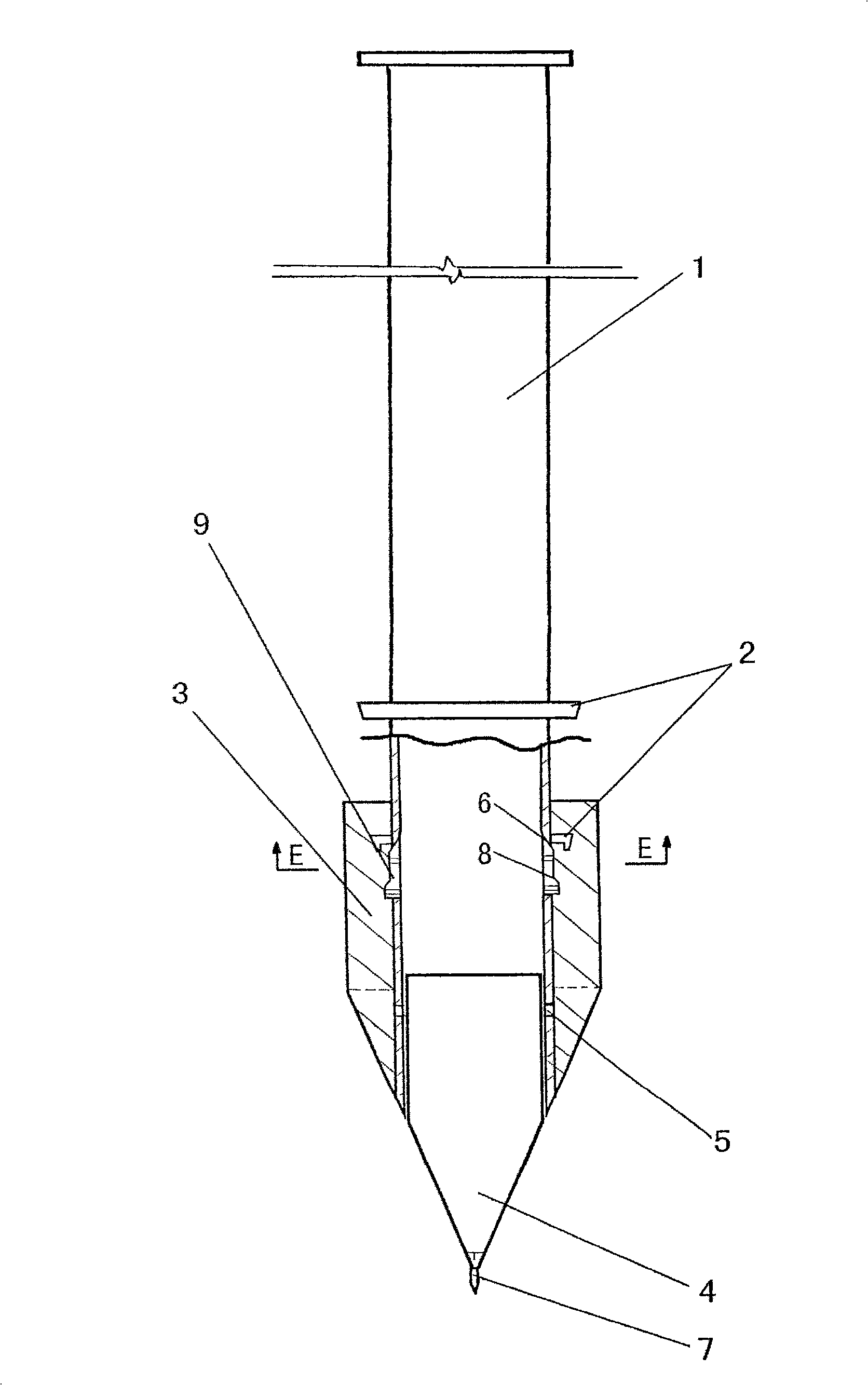

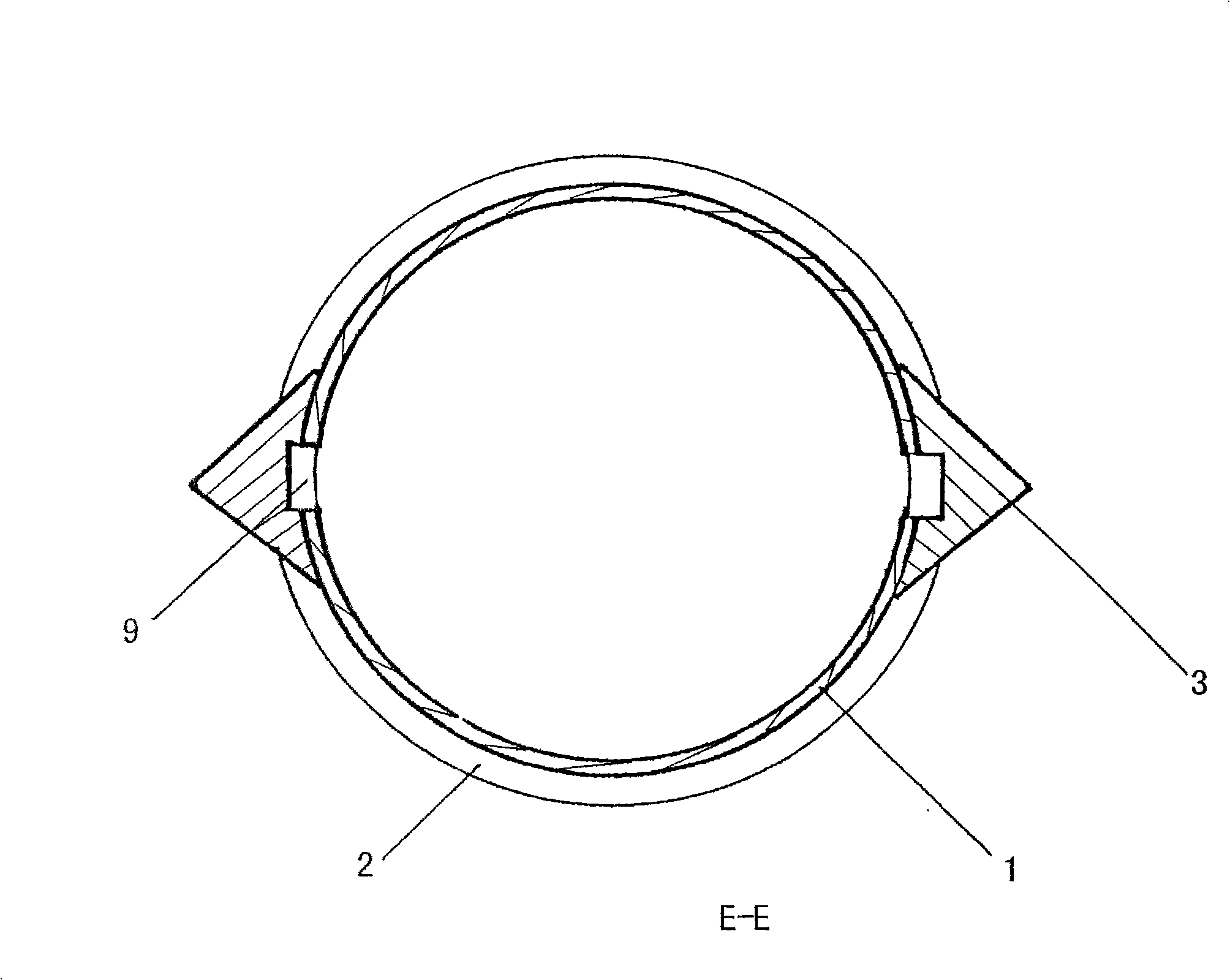

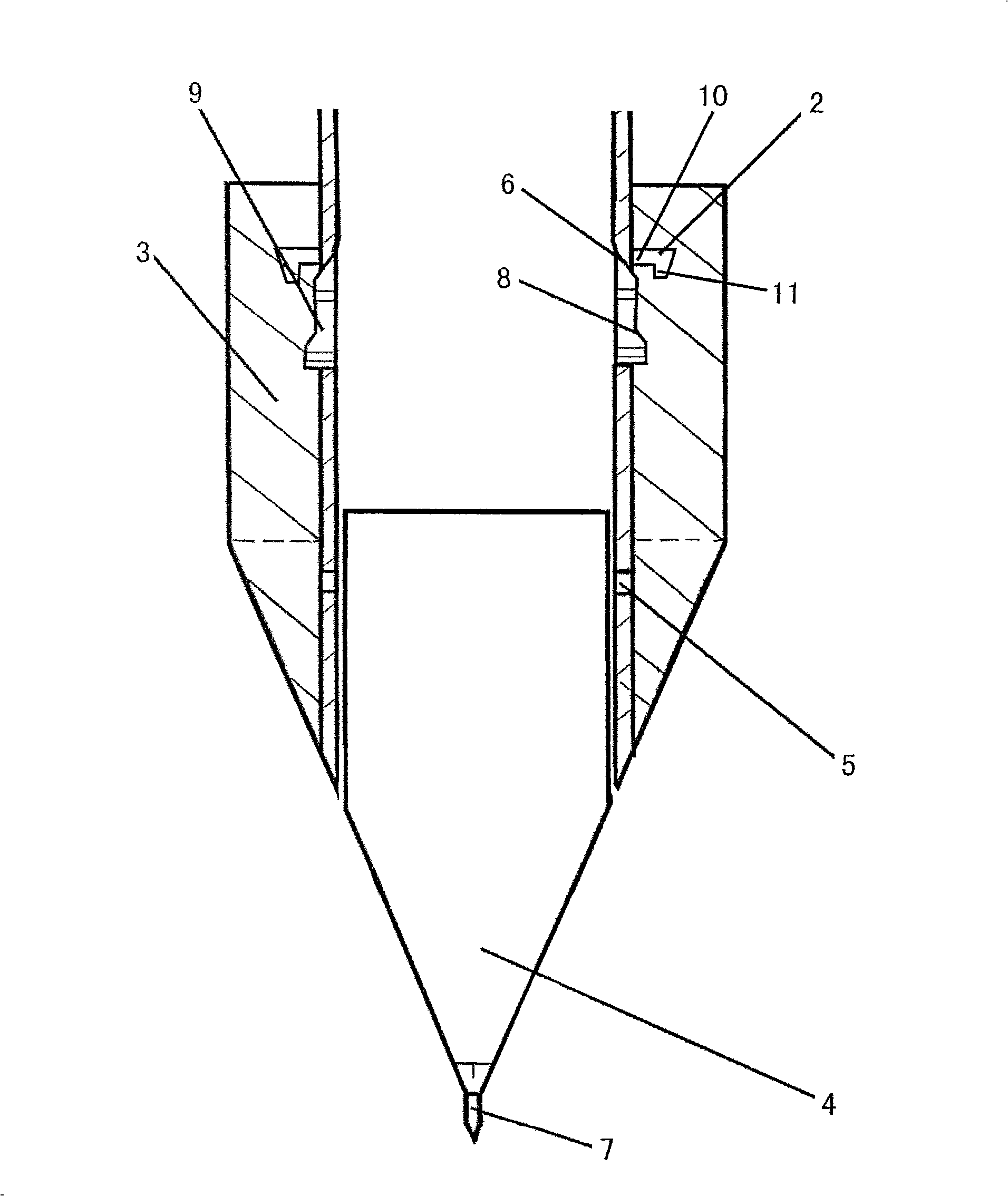

[0020] like figure 1 , figure 2 and image 3 As shown, the outer wall of the bottom connected to the pipe body 1 is evenly distributed in the circumferential direction with at least two guide wings 3, and the inner side of the bottom is provided with positioning pins matching the positioning iron feet of the existing earth-moving equipment at the position corresponding to the guide wings 3. Groove 9, the upper port of the pipe body 1 is provided with a positioning mark at the position corresponding to the positioning groove 9 inside the bottom along the circumferential direction. Coinciding with the outer end of the positioning iron foot, the positioning groove 9 has two slopes which are the upper slope 6 of the positioning groove and the lower slope 8 of the positioning groove. The setting purpose of the two slopes is to gradually increase the depth of the positioning groove 9. The tube body 1 and the bottom are made into an integrated structure. The section of pipe body ...

Embodiment 2

[0022] The sealing ring 2 described in Embodiment 1, such as Figure 4 Shown can adopt following structure: it is made of metal ring body 10 and the rubber ring 12 that is arranged on metal ring body 10 lower ends, and the diameter of rubber ring 12 is less than the diameter of metal ring body 10, and other structures are with embodiment one.

Embodiment 3

[0024] The sealing ring 2 described in Embodiment 1, such as Figure 5 The following structure can be adopted as shown: it consists of a metal ring body 10 and a circle of flange 11 located at its upper end. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com