Strong push type detaching mechanism of car clutch

A separation mechanism and clutch technology, applied in the direction of clutches, mechanical drive clutches, mechanical equipment, etc., can solve problems such as separation mechanism failure, and achieve the effects of improving separation efficiency, increasing service life, and improving strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

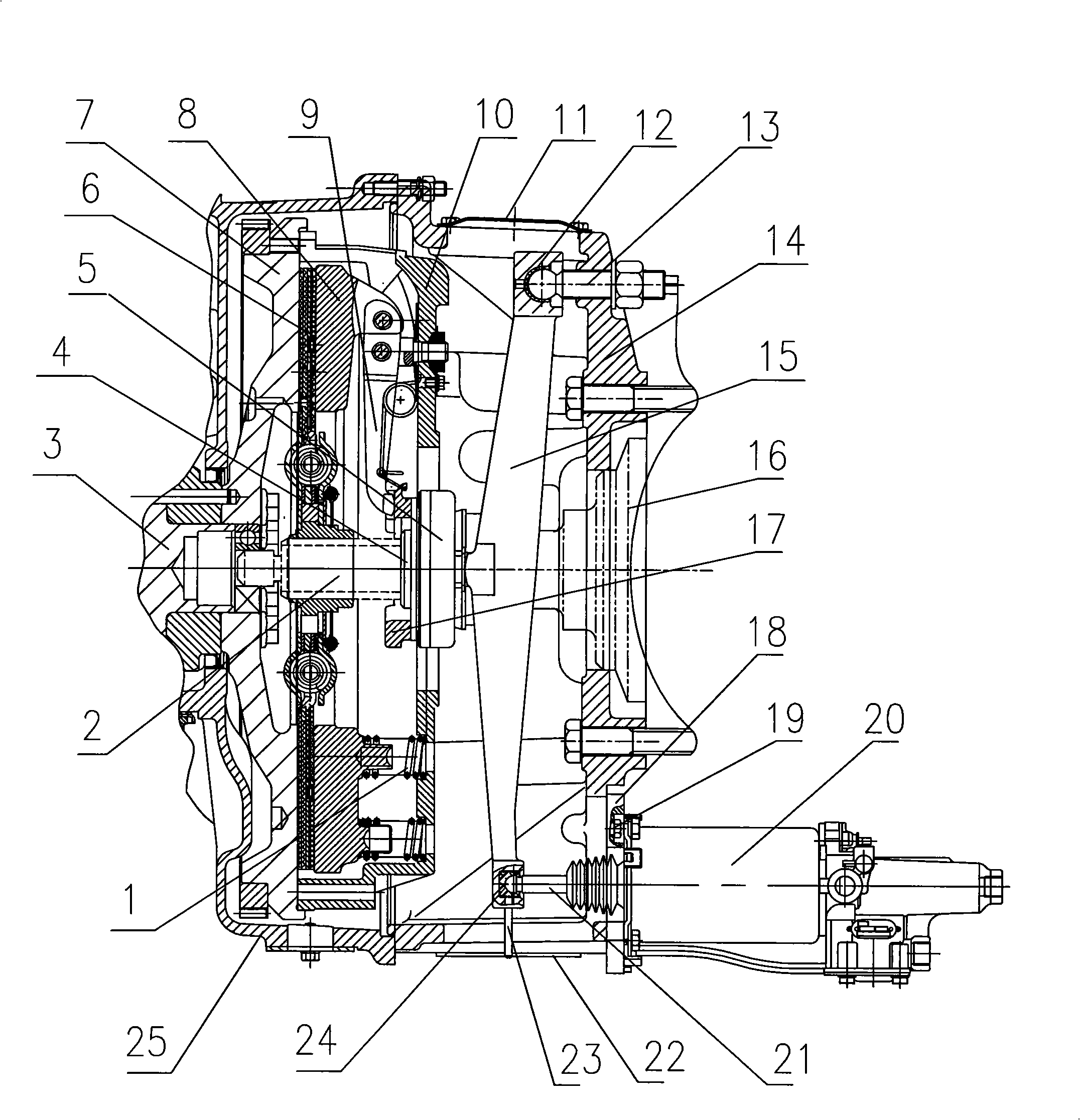

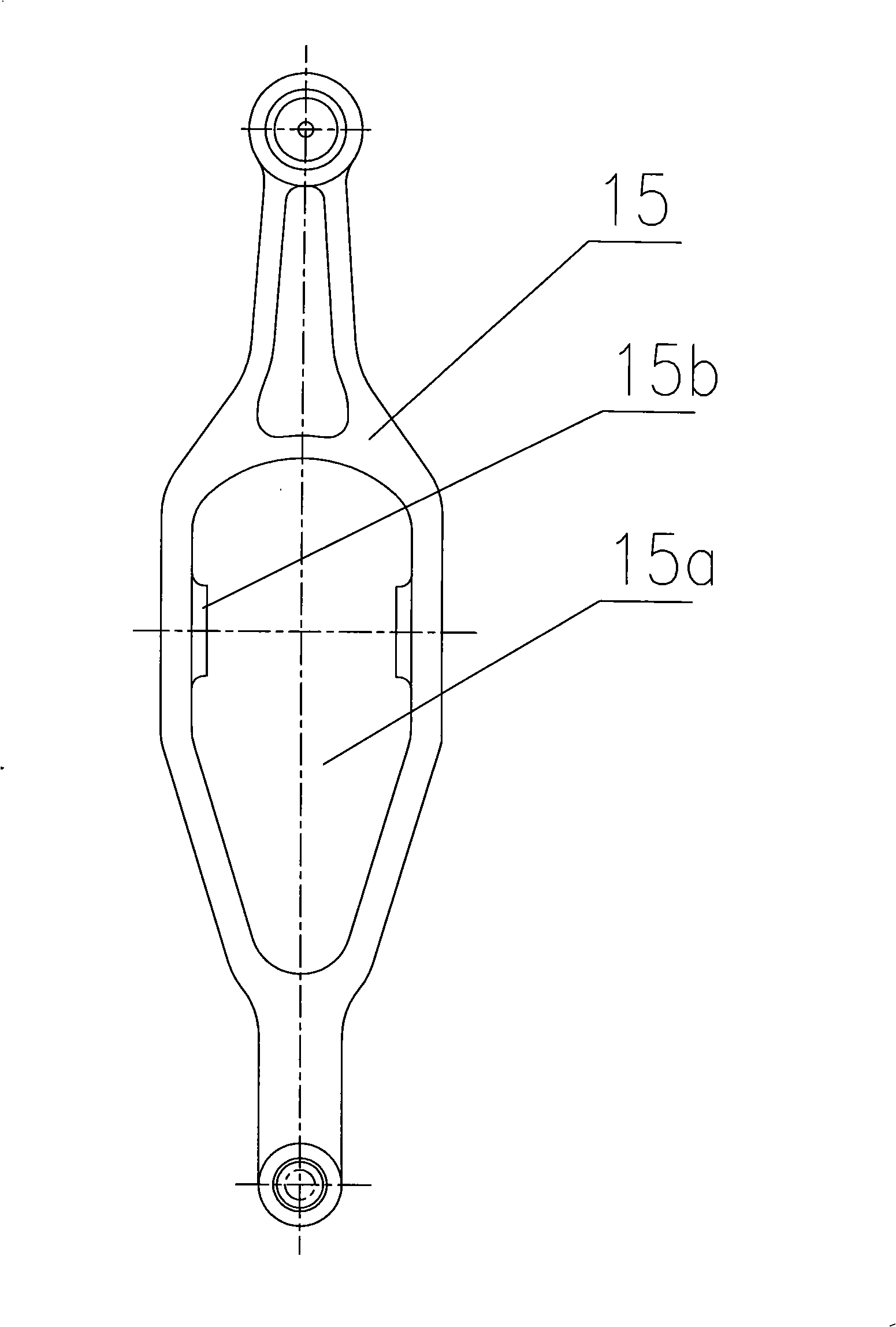

[0012] see figure 1 , figure 2 , a kind of embodiment of the strong push type separation mechanism of automobile clutch of the present invention. A disengagement push arm 15 is arranged inside the clutch housing 14 . The disengagement push arm 15 has a structure in which the middle part is wider than both ends, and the middle part is provided with a hole 15 a for making way. The hole 15a for giving way is a flat hole, the length of the flat hole extends along the arm length direction of the separation push arm, the width of the flat hole extends along the arm width direction of the separation push arm, and the flat hole can be set as a rectangular hole, or An oval hole, or a hole in a shape that is wider on one side than the other. The middle part of the separation push arm 15 is located on both sides of the hole 15 for giving way, and is provided with a protrusion 15b in contact with the end surface of the release bearing 5. The protrusion 15b is symmetrically arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com