Method for coating thin epoxy resin of amorphous alloy iron core

A technology of epoxy resin coating and amorphous alloy, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problem of no-load loss and increase of excitation power, long curing time of epoxy resin, and increase of transformer loss And other problems, to achieve the effect of low no-load loss, shorten curing time, and small no-load current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

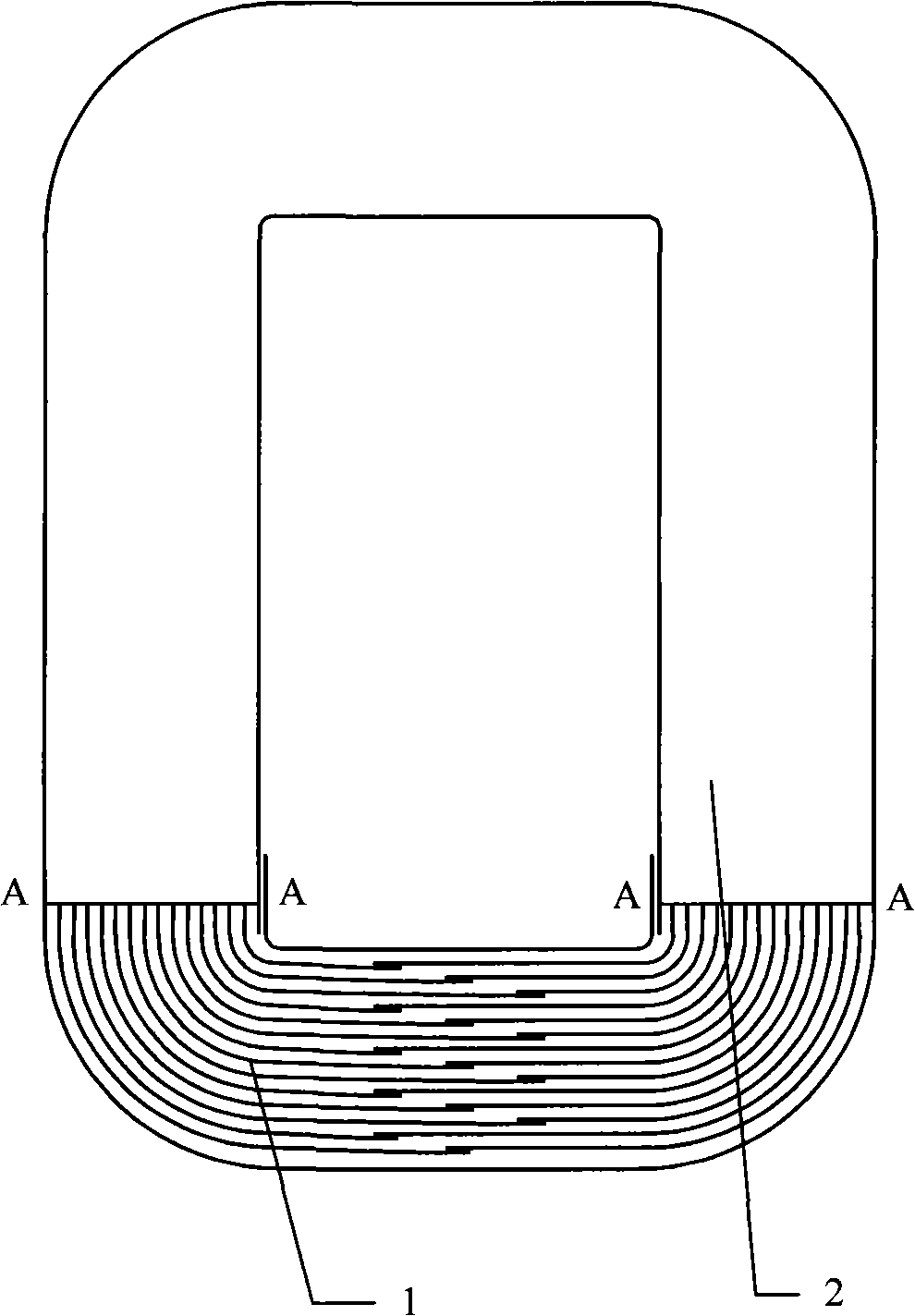

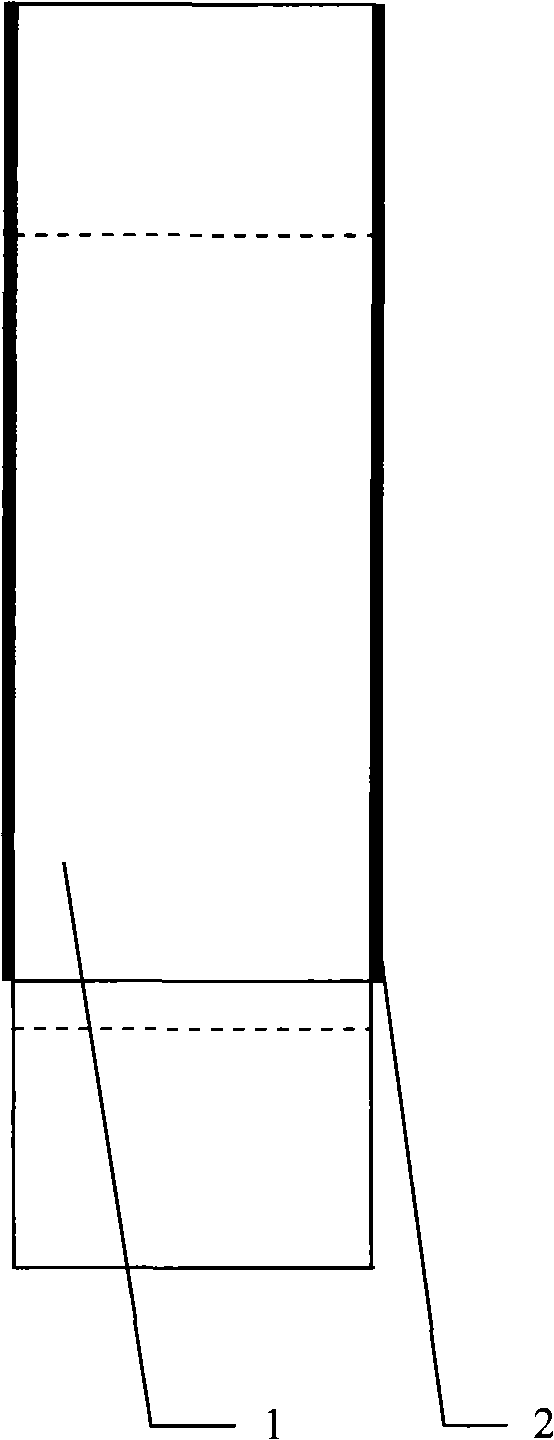

[0019] like figure 1 , 2 As shown, it is a structural schematic diagram of an amorphous alloy iron core with a thin epoxy resin, and a method for coating an amorphous alloy iron core with a thin epoxy resin is:

[0020] Step 1: Use a brush to remove dust on the surface of the amorphous alloy core 1;

[0021] Step 2: On the amorphous alloy core 1, paste a tape with a width of 1 cm below the line A-A to prevent the epoxy resin from leaking out;

[0022] Step 3: Use a brush to evenly brush the epoxy resin 2 on the surface of the iron core above the line A-A of the amorphous alloy iron core 1, and the thickness of the epoxy resin 2 is less than 1mm;

[0023] Step 4: Put the coated amorphous alloy iron core 1 into an oven for baking at a temperature of 130° C. for 20 minutes, and then take it out;

[0024] Step 5: Turn the amorphous iron core over on the reversing table; repeat steps 1 to 4 on the other side of the iron core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com