Pyromagnetic release

A technology of thermal magnetic release and tripping, which is applied in the direction of protection switch operation/release mechanism, etc. It can solve the problems of unreliable action, complex structure, cumbersome tripping process, etc., and achieve the effect of reliable action and simple tripping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

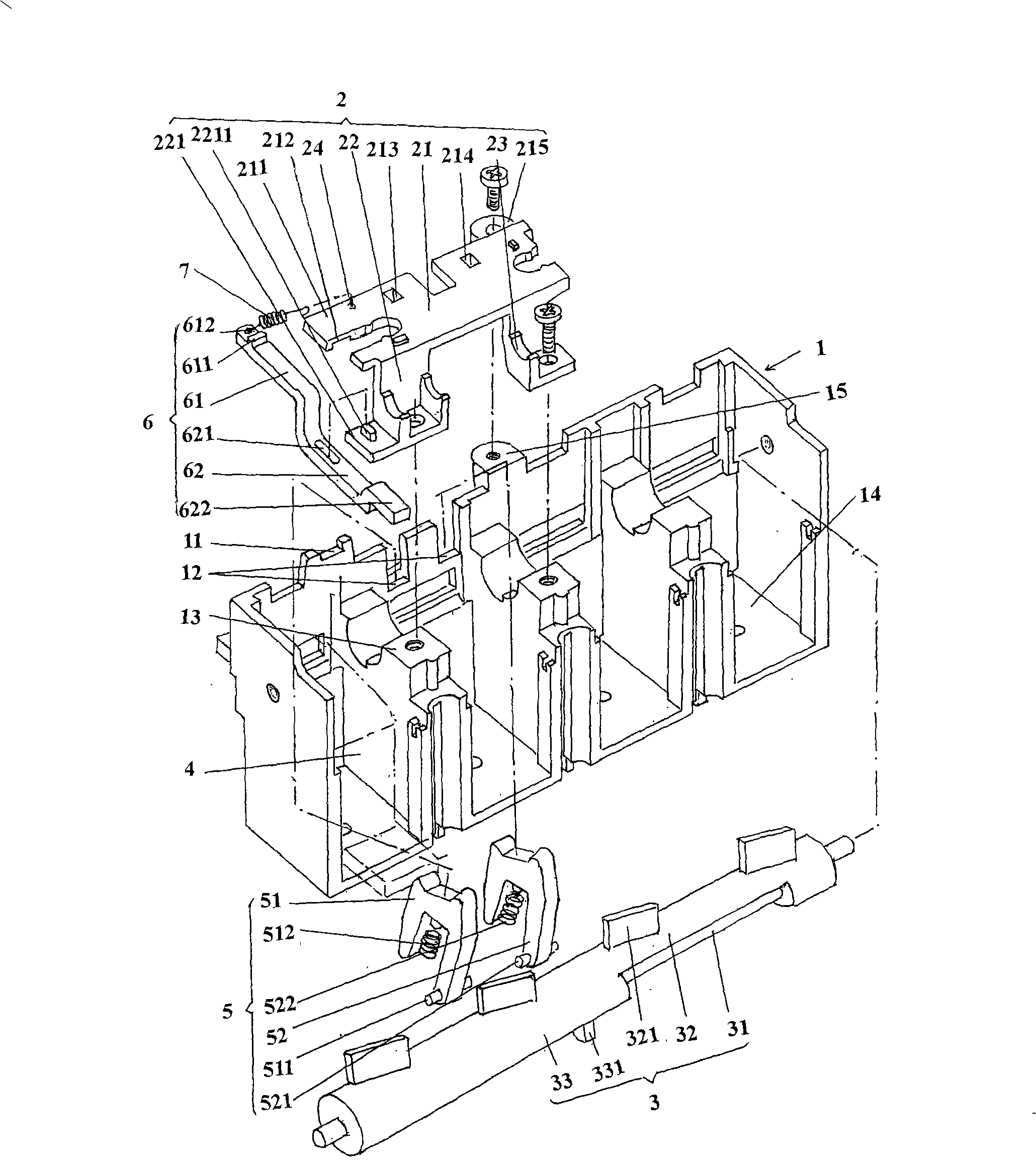

[0023] Embodiment 1: The push rod 6 is installed between the bracket 2 and the base 1 .

[0024] The thermal-magnetic release of this embodiment is suitable for thermal-magnetic adjustable and non-adjustable thermal-magnetic circuit breakers, and is also suitable for circuit breakers with fault indication.

[0025] please see figure 1 and figure 2 , gives the base 1 on which four thermal-magnetic protection devices 4 can be installed, specifically: on one side of the base 1 in the length direction, that is, the current figure 1 The front side of the shown position state is divided into four thermal-magnetic protection device accommodation cavities 14, and four thermal-magnetic protection devices 4 are arranged in the four thermal-magnetic protection device accommodation cavities 14, thereby forming a four-pole circuit breaker , based on this principle, if three thermal-magnetic protection devices 4 are used, then it will appear as a three-pole circuit breaker, so this embod...

Embodiment 2

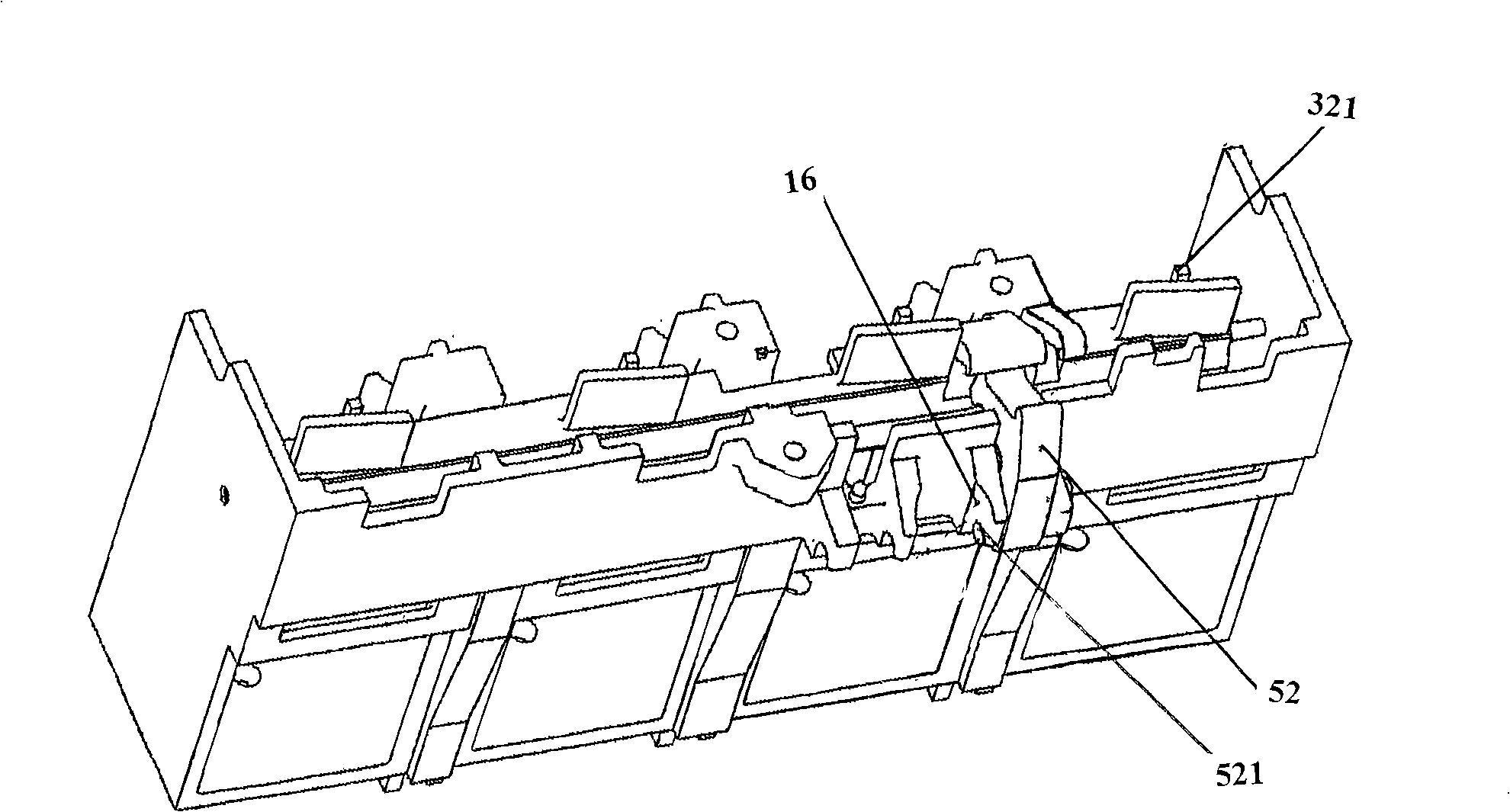

[0030] Embodiment 2: The push rod 6 is installed on the base 1 .

[0031] please see Figure 4 and Figure 6 , the present embodiment is applicable both with the support 2 and without the support 2, the barrier 13 for separating the thermomagnetic protection device 4 on the base 1 is extended with a section of boss 131, on the boss 131 A guide protrusion 1311 is added, and the guide hole 621 of the push rod 6 matches with the guide protrusion 1311 .

[0032] Whether the circuit breaker is equipped with a bracket or without a bracket 2, the upper limit of the push rod 6 can be limited by a stop protrusion 91 provided in the upper cover 9 of the circuit breaker, and the upper cover 9 and the base 1 are closed Finally, the stop protrusion 91 and the guide slide groove 11 on the base 1 are combined into a guide slide groove hole, thereby the push rod 6 can be limited, and when the push rod 6 is reset, the stop protrusion 611 and The blocking protrusion 91 in the loam cake 9 con...

Embodiment 3

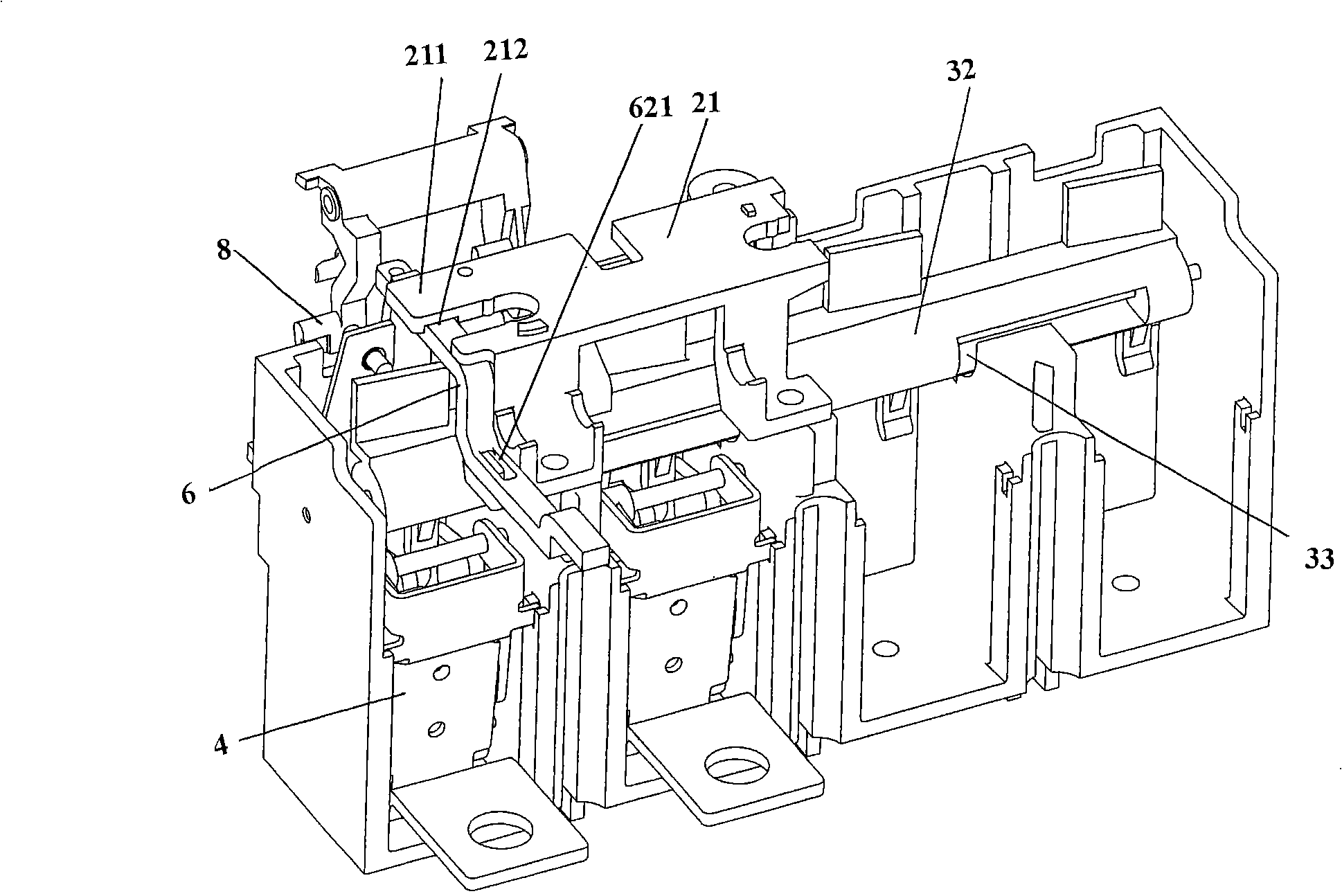

[0034] Embodiment 3: The push rod 6 is installed on the bracket 2 .

[0035] please see Figure 5 and Figure 7 , the support 2 of the present embodiment is based on the structure of the support 2 of the first embodiment and then a guide slide hole 216 is opened at the corresponding position of the notch blocking protrusion 211, so that the push rod 6 is installed in the guide slide hole 216 of the support 2, and the push rod 6 is additionally provided with a boss 623 for the limit of push rod 6 reset, when push rod 6 resets, moves to boss 623 and the side wall 92 contact of loam cake 9 ( Figure 7 Shown), that is, stop the movement, so that the push rod 6 will not fall off from the guide slide hole 216.

[0036] The thermal-magnetic release of this embodiment is suitable for thermal-magnetic adjustable and thermal-magnetic non-adjustable circuit breakers, and can also be used for circuit breakers with fault indication.

[0037] Please combine Figure 1 to Figure 5 , the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com