Pressure disc type filter

A filter and pressure plate technology, applied in filtration and separation, moving filter element filters, separation methods, etc., can solve the problems of large equipment and small filter surface, and achieve compact structure, high sealing performance, and increased production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

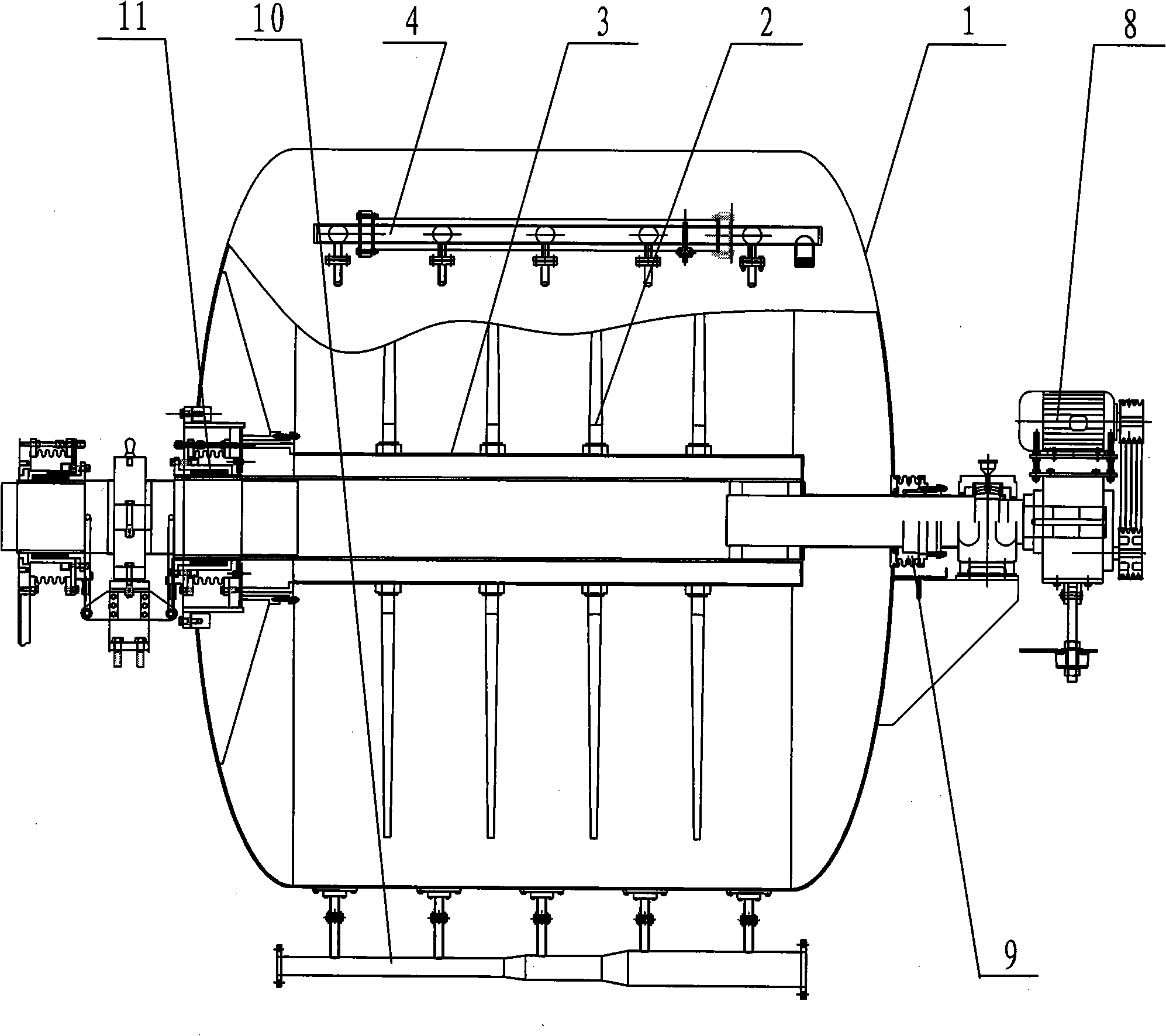

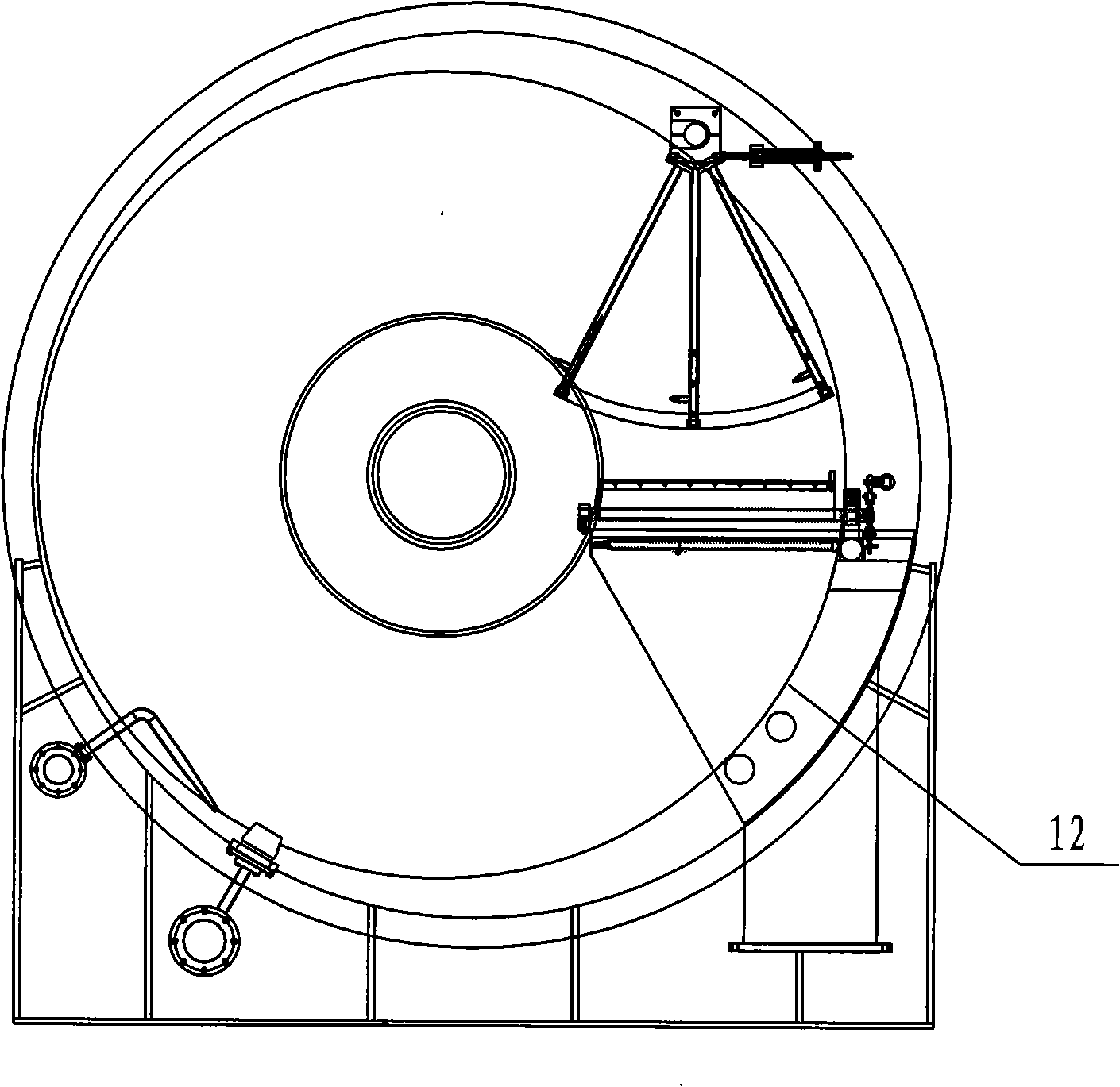

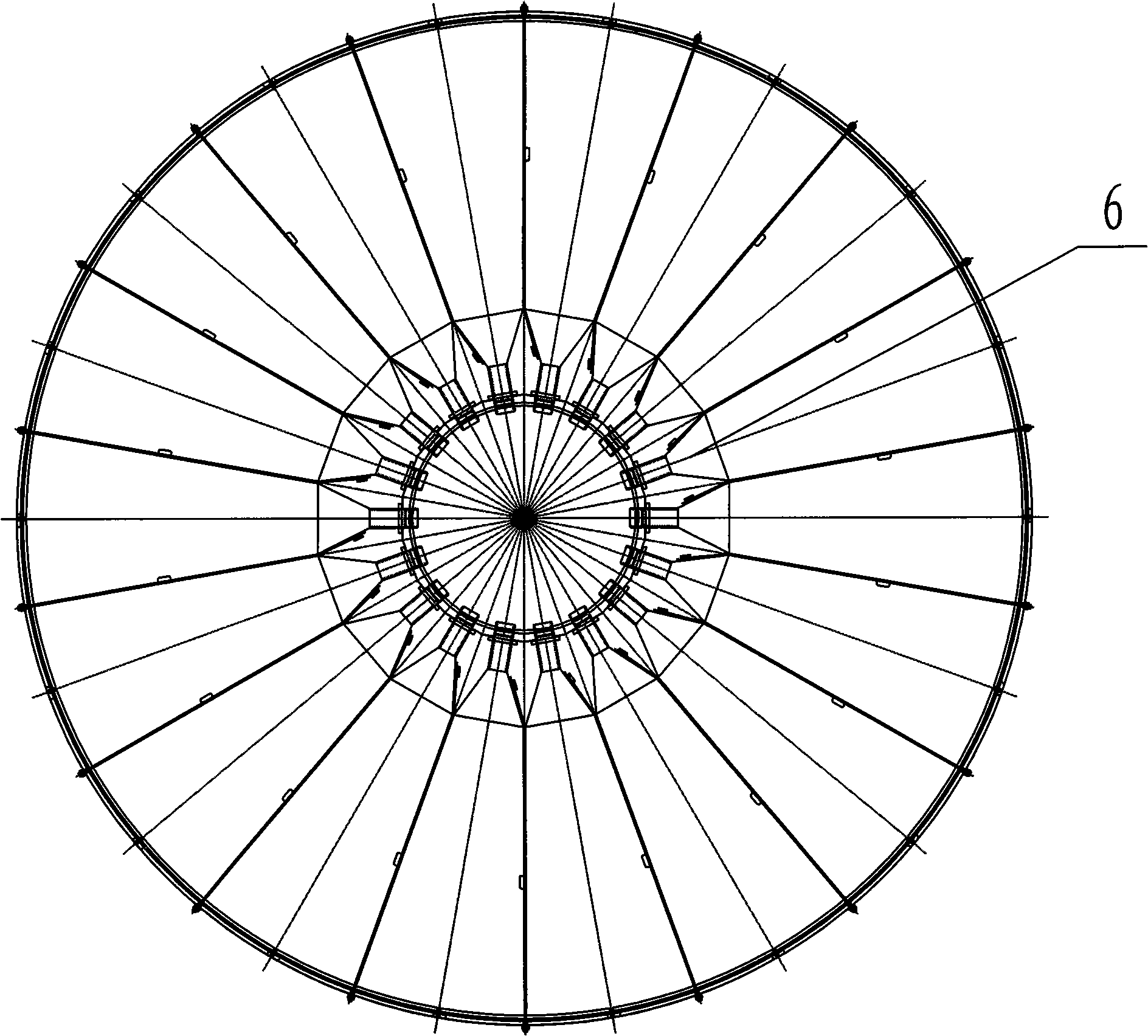

[0024] As shown in the drawings, a pressure disc filter includes a hollow shaft 3 , a filter device fixed on the hollow shaft 3 , a scraper device for unloading, a main transmission device 8 and a tank body 1 . The main transmission device 8 adopts a direct-connected suspension type reducer, and frequency conversion speed regulation. The tank body 1 is a sealed pressure tank body composed of a cylinder body and two heads. One end of the tank body and the hollow shaft is provided with an end sealing device 9 to seal the tank body. The bottom of the tank body 1 is provided with a feeding device 10 communicating with the inside of the tank body. The filter device includes a circular filter disc 2 arranged axially along the hollow shaft 3, each circular filter disc 2 is composed of at least 12 cavities arranged along the circular surface, and the cavity of the filter disc 2 is composed of two surfaces with The top-closed fan-shaped cavity formed by the fan-shaped plate with smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com