Flame-retardant color master batch for environment-protective case material

A casing and color masterbatch technology, which is applied in the field of flame-retardant color masterbatch for environmental protection casing materials, can solve the problems of low flame-retardant efficiency, high cost of flame-retardant casing, and unsatisfactory effect of flame retardants, etc., to reduce production costs , good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

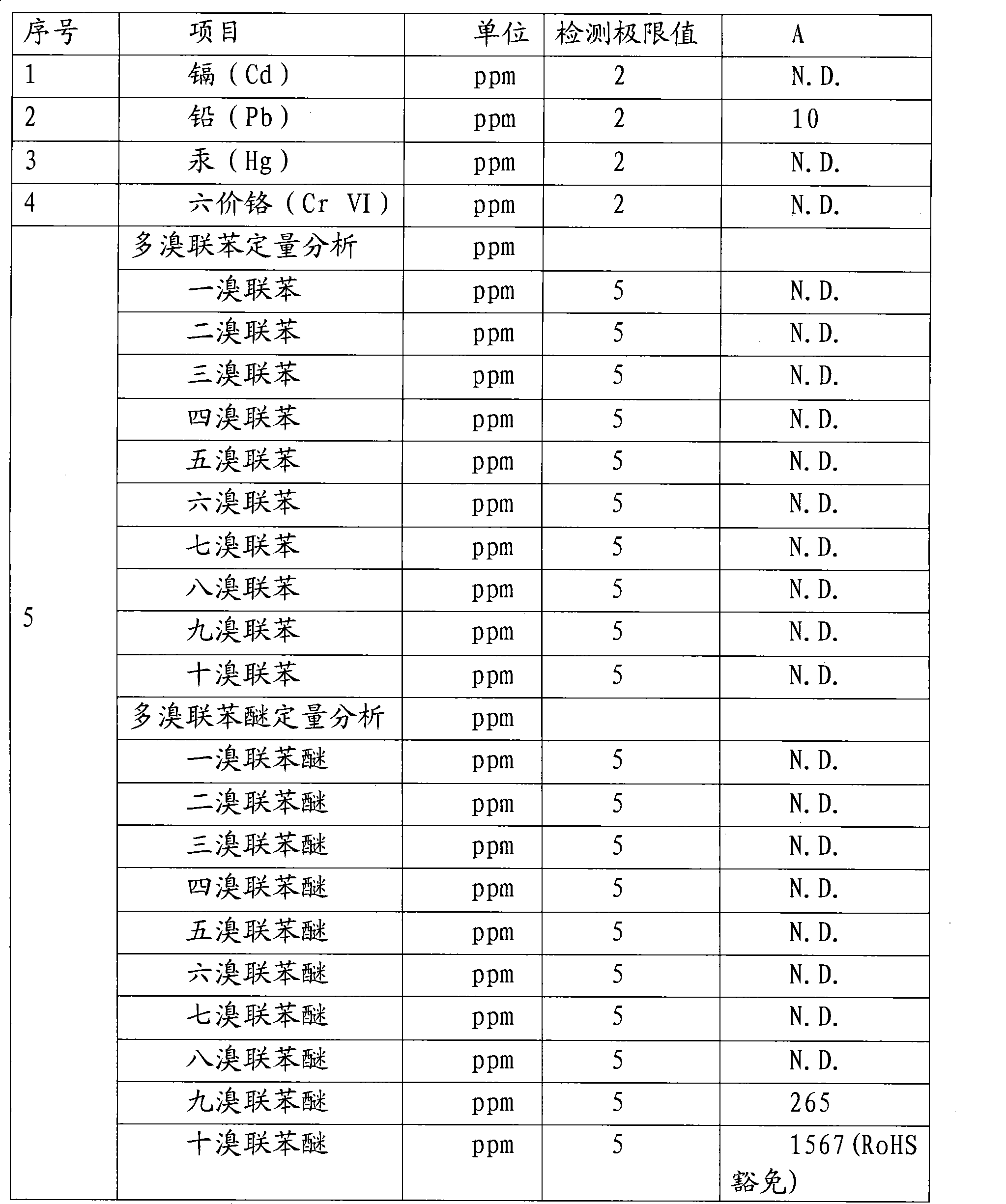

Image

Examples

Embodiment 1

[0019] Get 35 parts by weight of decabromodiphenylethane (TDE), 50 parts of brominated epoxy (BER), 10 parts of antimony trioxide (Sb 2 o 3 ), by conventional dispersion, mixing and granulation equipment and techniques, the product of the present invention can be obtained.

Embodiment 2

[0021] Get 25 parts by weight of decabromodiphenylethane (TDE), 30 parts of brominated epoxy (BER), 15 parts of antimony trioxide (Sb 2 o 3 ), by conventional dispersion, mixing and granulation equipment and techniques, the product of the present invention can be obtained.

Embodiment 3

[0023] Get 30 parts by weight of decabromodiphenylethane (TDE), 40 parts of brominated epoxy (BER), 18 parts of antimony trioxide (Sb 2 o 3 ), by conventional dispersion, mixing and granulation equipment and techniques, the product of the present invention can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com