Combustion type deferred blasting cap and deferred elements thereof

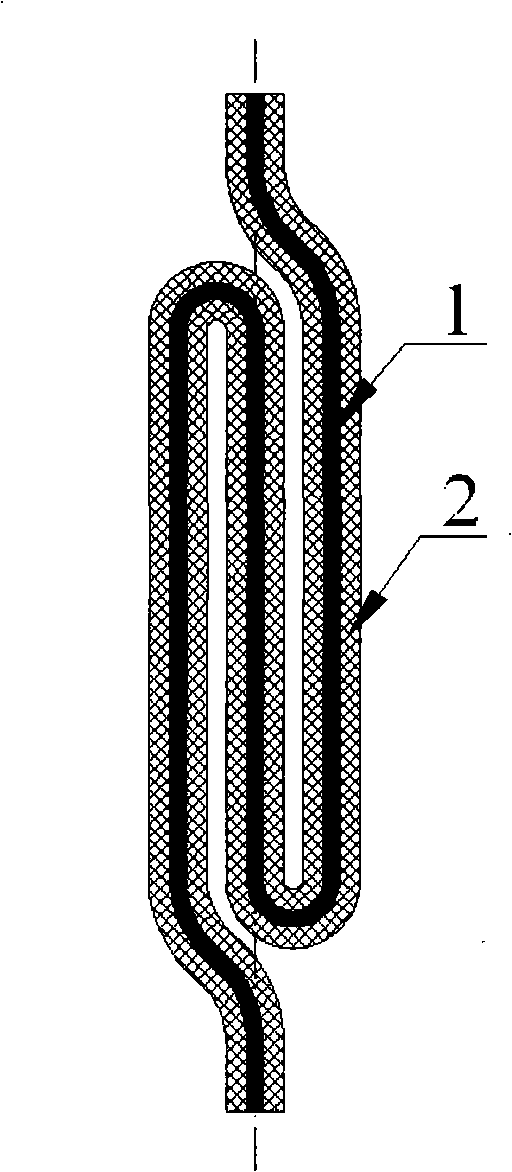

A technology of detonating detonators and detonators, which is applied in the field of delay components, can solve problems such as potential safety hazards, delay jumps, and unreliable ignition ability and stability of delay agents, and achieve strong adaptability, reduced overall length, and friendly production technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

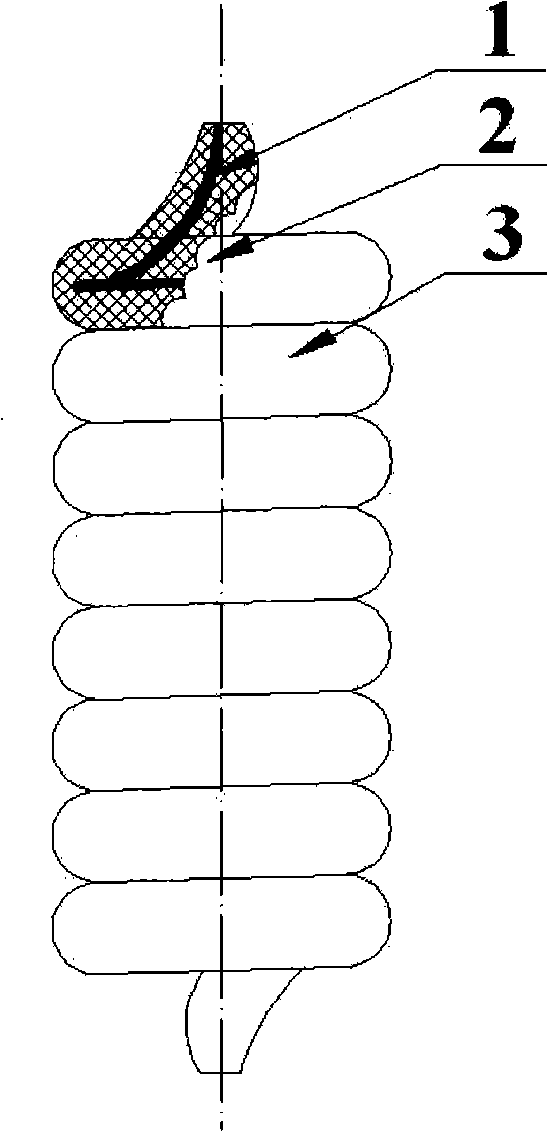

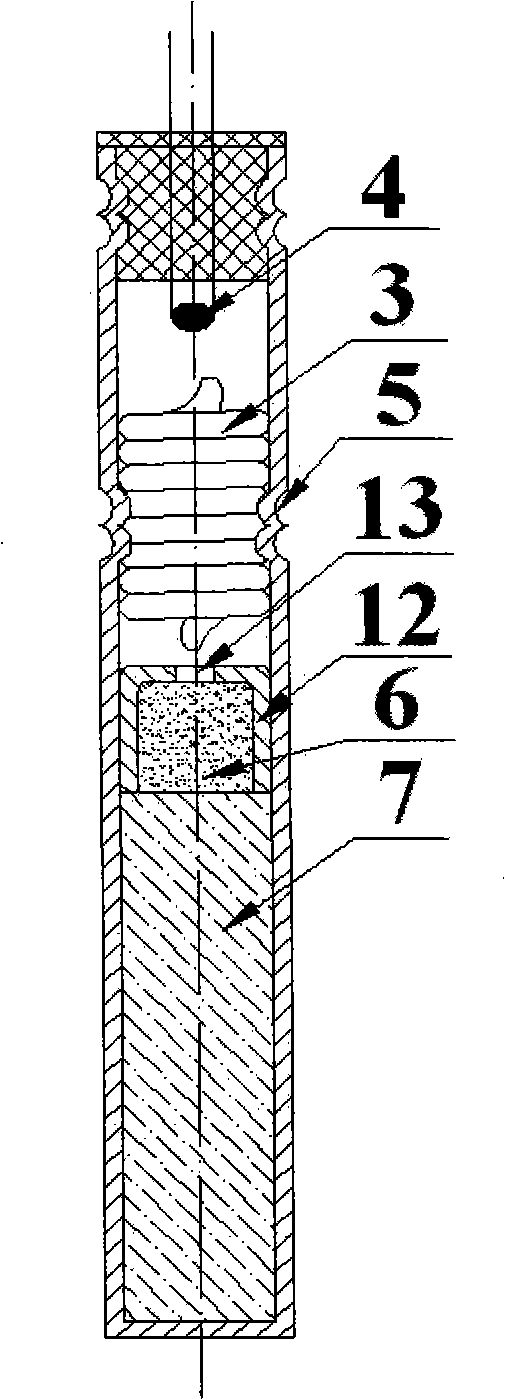

[0029] image 3 It is a detonator with detonating charge delay made of helical spring-like delay element. The shape of the helical spring-like delay element 3 used is visible figure 2, wherein the outer diameter of the extension tube used is 2.0 mm, the outer diameter of the "spring" is 5.0 mm, and the pitch is 5 turns / cm. The helical spring-like extension element 3 is fixedly connected with the detonator shell by the waist clip 5, and its upper protruding end face is about 3.0 mm away from the electric ignition charge 4 of the detonator, and the distance between the lower protruding end face and the fire transmission hole 13 of the reinforcing cap 12 is equal to 5 mm. . In actual use, after the electric ignition charge 4 is ignited, the exposed drug core on the protruding end surface of the delay element 3 is ignited immediately; Flame passes through the fire transmission hole 13 and detonates the primer 6. Under the action of the detonation wave of the priming charge 6,...

Embodiment 2

[0031] Figure 4 It is a delay electric detonator without priming charge made of helical spring delay element. The shape of the helical spring-like delay element 3 used is visible figure 2 , wherein the extension tube used has an outer diameter of 2.5 mm, a helical "spring" with an outer diameter of 6.0 mm, and a pitch of 4 turns / cm. The helical spring-like extension element is placed in the inner cap 11, and is fixedly connected with the detonator shell by the waist clip 5. The upper protruding end surface is about 5.0 mm away from the electric ignition powder head 4 of the detonator, and the lower protruding end surface is in contact with the excitation charge 10. In actual use, after the electric ignition charge 4 is ignited, the exposed drug core on the protruding end surface of the delay element 3 is ignited immediately; Ignition propellant 10. Under the combustion action of the propellant 10, a high-speed flying piece is formed at the bottom of the inner cap 11, whic...

Embodiment 3

[0033] Figure 5 It is a non-priming non-electric delay detonator made of a helical spring-like delay element in a non-priming non-electric detonator. Among them, the outer diameter of the delay tube used is 2.7 mm, and the outer diameter of the helical "spring" is 6.4 mm. The nonel tube 8 cooperates with the bayonet plug 9 to play the role of sealing the detonator and transmitting the detonation signal; the helical spring-like delay element 3 The waist card 5 is fixedly connected with the detonator shell, and its upper end face is about 2.0 mm away from the nonel 8 port, and the lower end face is in contact with the excitation charge 10 . After the detonation wave propagates to the nozzle inside the detonation tube 8, under the action of the shock wave and flame, the exposed drug core on the upper end surface of the delay element 3 is ignited; after a period of burning time, the other end surface of the delay element 3 The medicine core burns, ejects flame outwards, and igni...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap