Material sampler for detecting acoustical material

A technology of acoustic materials and sampling machines, applied in sampling devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems that it is difficult to ensure the consistency between the material sample diameter and the inner diameter of the impedance tube and the flatness of the section, and achieve a simple structure , easy to operate, and ensure consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

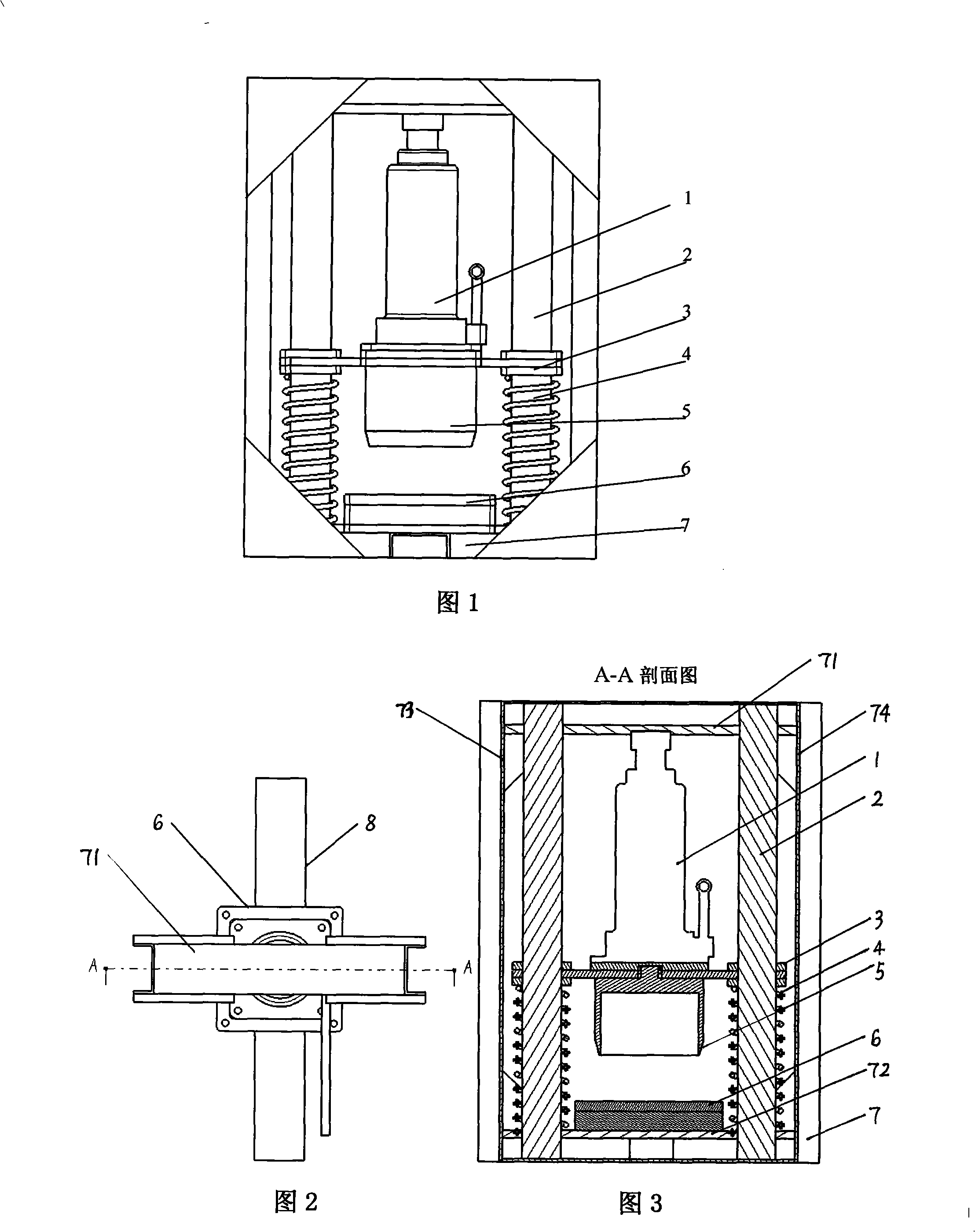

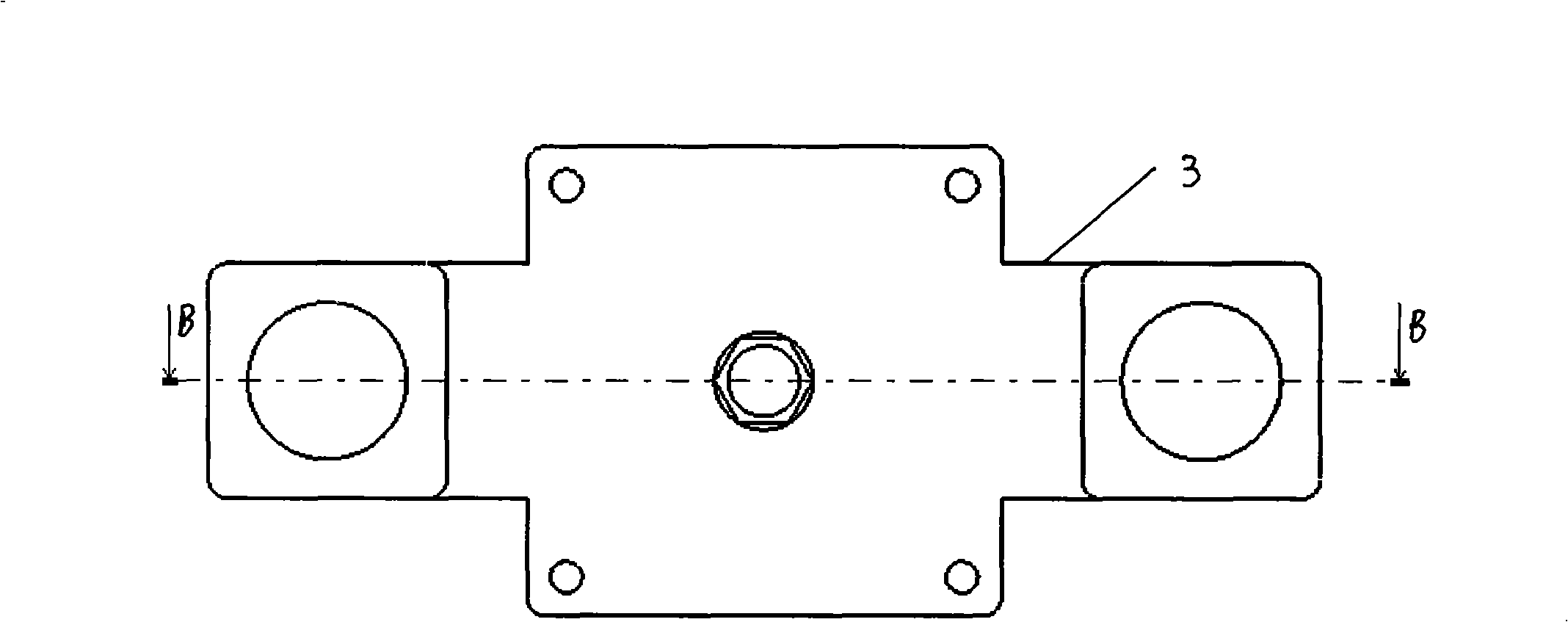

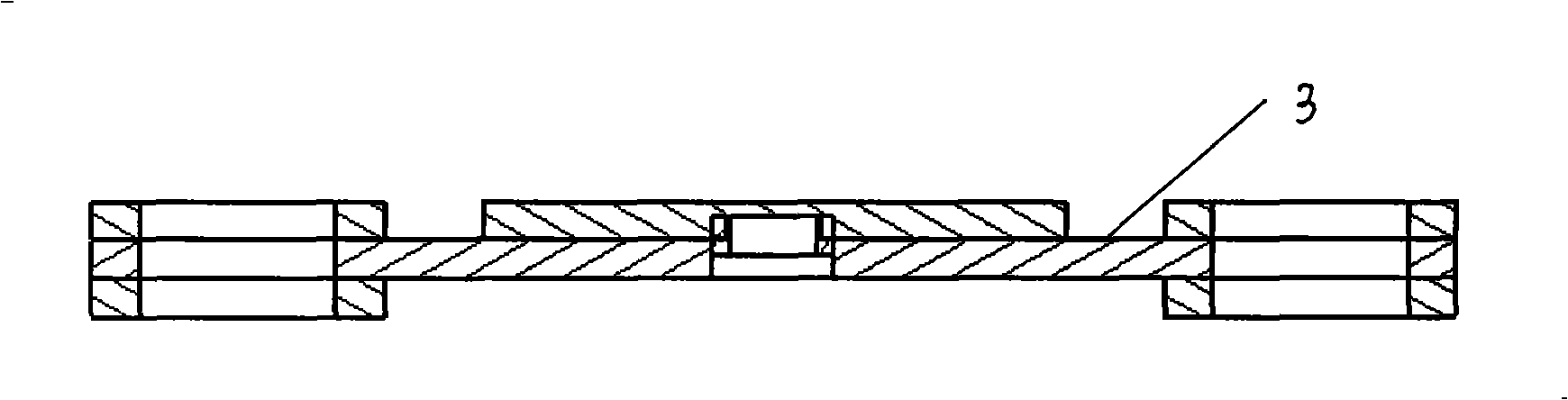

[0013] As shown in Figure 1, Figure 2 and Figure 3, the material sampling machine is composed of a frame 7, a hydraulic jack 1, a guide column 2, a balance plate 3, a spring 4, a cutter 5 and a backing plate 6. Rack: It is composed of upper and lower horizontal columns and left and right columns. The frame 7 is a frame structure composed of upper and lower horizontal columns 71, 72 and left and right vertical columns 73, 74. Two guide columns 2 are vertically fixedly connected between the upper and lower horizontal columns 71 and 72 for guiding the movement of the balance board. The surface precision of the guide post is required to be high. The balance board 3 is guided on the guide post 2, see Figure 3 and Figure 4 , a bolt is inlaid in the middle of the balance plate for connecting the cutter 5, the two ends of the balance plate are relatively thick, so that it is convenient to ensure that the balance plate is in a horizontal position during motion, and the precision of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com