Ultrasonic electrochemical method for accurately evaluating stainless steel pitting potential

A technology of pitting potential and stainless steel, which is applied in scientific instruments, preparation of test samples, weather resistance/light resistance/corrosion resistance, etc. It can solve problems such as difficulty in controlling heating rate, crevice corrosion, and difficulty in sealing samples at changing temperatures. Effect of eliminating data dispersion and accurate potential data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

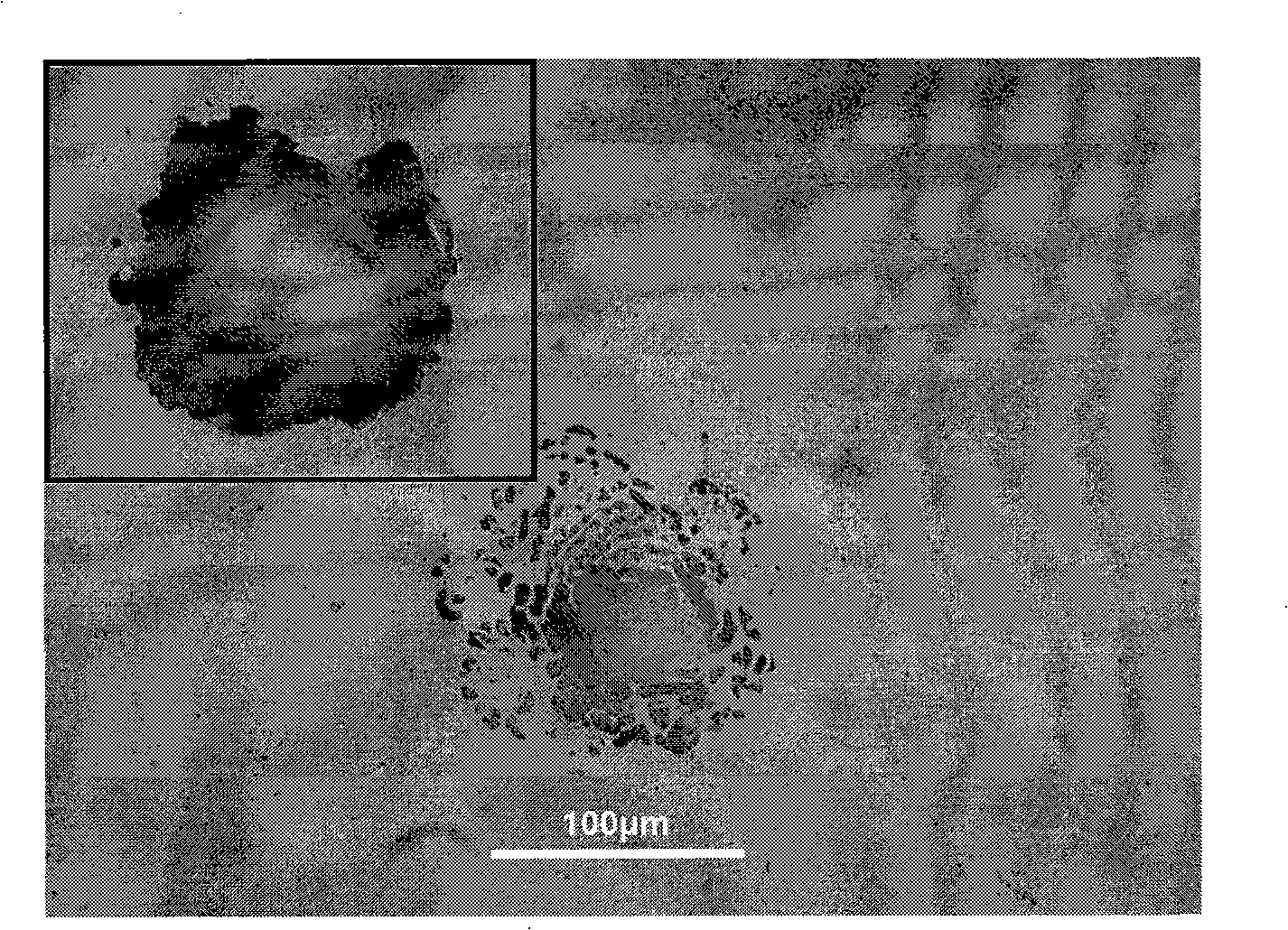

[0021] Example 1 Pitting corrosion performance evaluation of 316 stainless steel ultrasonic potential polarization curve

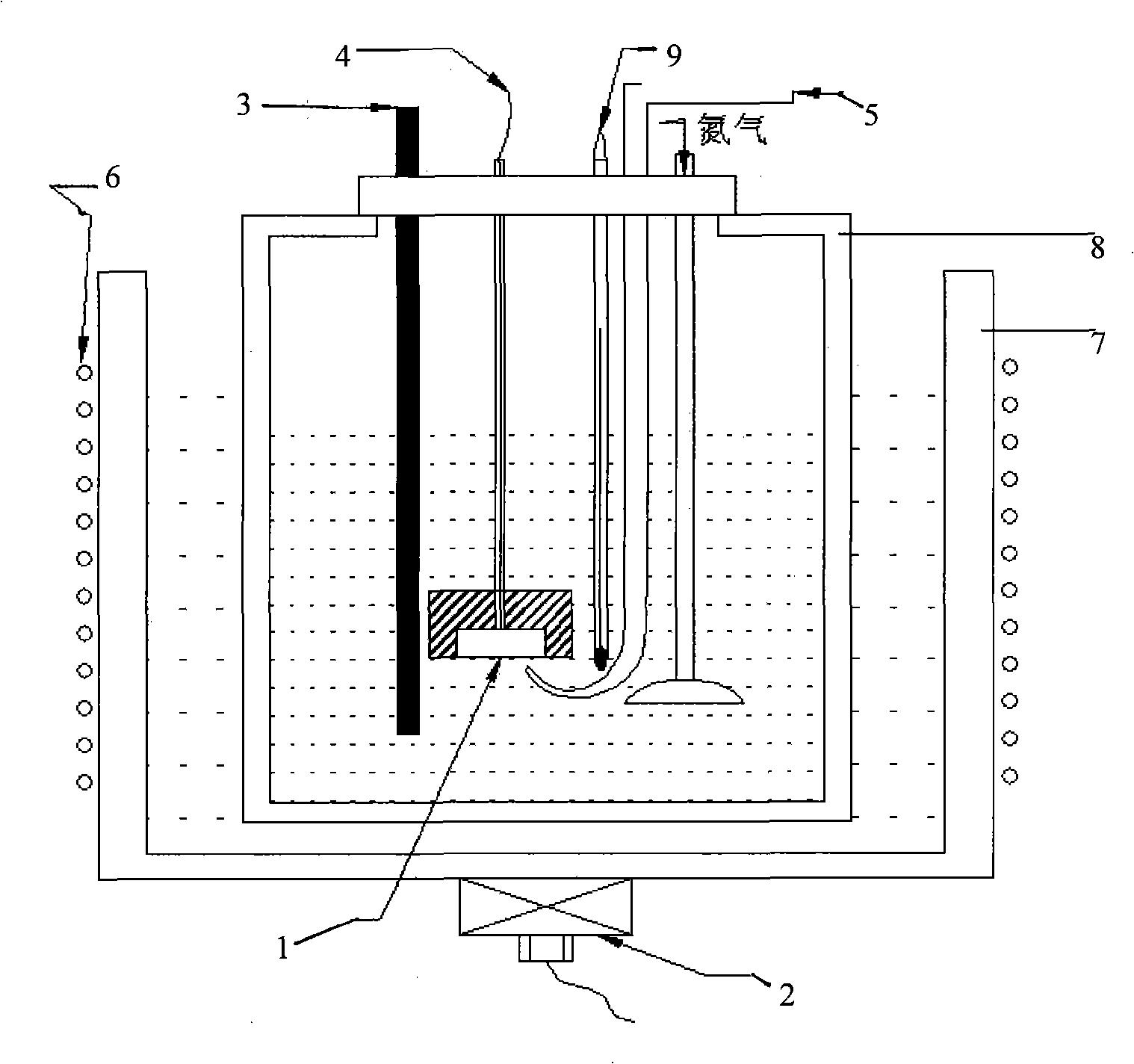

[0022] For 316 stainless steel, use the above steps to measure in the invented electrolytic cell with ultrasonic generator, seal the non-working surface with epoxy resin, leave only about 10mm×10mm surface and conduct polarization curve test. The specific conditions for the polarization curve test are: accurately prepare 1mol / L NaCl solution, place it in a water bath, and keep the temperature at 25°C; before the experiment, first pass high-purity nitrogen (99.999%) into the medium solution for 30 minutes to remove oxygen, During the test, ventilation and deoxygenation were continued. A standard three-electrode system was used for electrochemistry: the auxiliary electrode was a graphite electrode; the reference electrode system was composed of a saturated calomel electrode (SCE) and a salt bridge. The test results are as Figure 5 shown, at higher than Eb...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap