Pressure-sensitive adhesive optical film and image display

An optical film, adhesive technology, applied in the direction of adhesive type, optics, optical components, etc., can solve the problems of adverse effects of durability, poor appearance, deterioration of adhesives, etc., to suppress display unevenness and improve display. The effect of contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

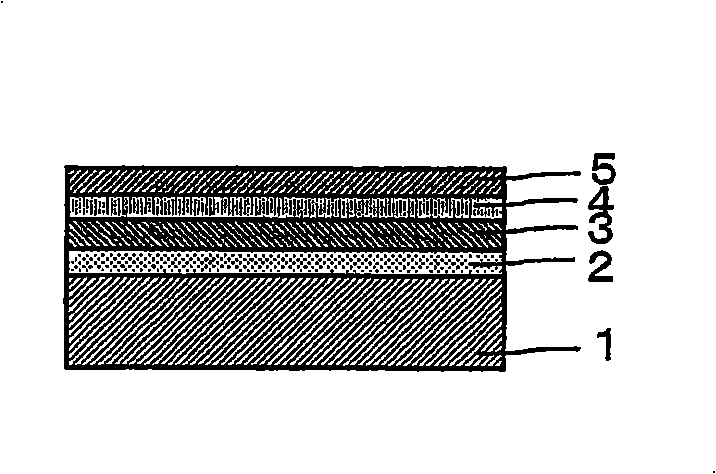

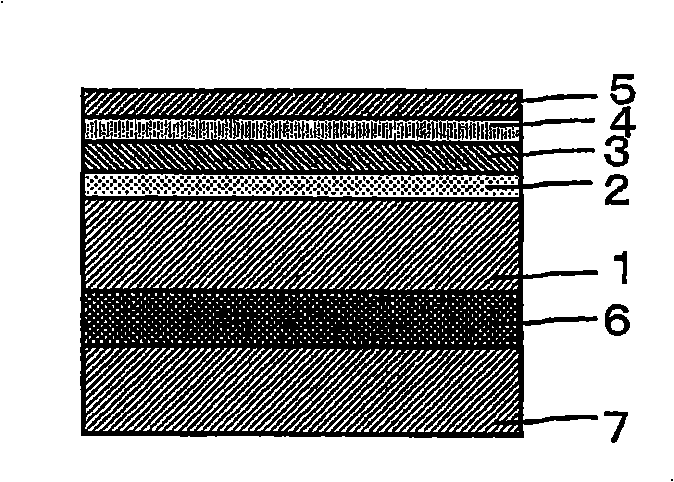

Image

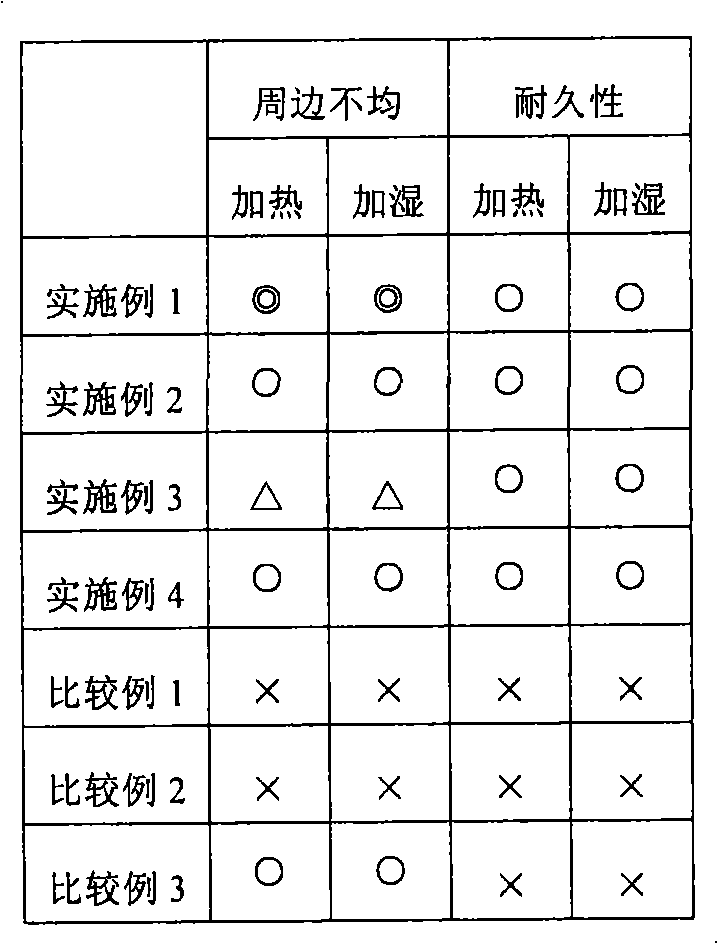

Examples

Embodiment 1

[0171] (Preparation of Acrylic Polymer (a1))

[0172]In a 4-neck flask equipped with a stirring paddle, a thermometer, a nitrogen inlet pipe, and a condenser, add 100 parts by weight of butyl acrylate (BA), 1 part by weight of 2-hydroxybutyl acrylate, and 0.3 parts by weight of 2 as a polymerization initiator. 2'-Azobisisobutyronitrile and 50 parts by weight of ethyl acetate were stirred slowly while nitrogen gas was introduced to carry out sufficient nitrogen replacement, and then the liquid temperature in the flask was kept at around 55°C for 8 hours of polymerization. Prepare an acrylic polymer (a1) solution. The weight average molecular weight of the said acrylic polymer (a1) was 1.5 million.

[0173] (Preparation of urethane polymer (b1))

[0174] In a 4-neck flask equipped with a stirring paddle, a thermometer, a nitrogen inlet pipe and a condenser pipe, add 75 parts by weight of polyoxytetramethylene glycol and 0.05 part by weight of dibutyltin dilaurate, slowly stir ...

Embodiment 2

[0181] In Example 1, instead of 30 parts by weight of the urethane polymer (b1), 150 parts by weight of the urethane polymer (b1) was used, and it was carried out in the same manner as in Example 1, Make adhesive optical films.

Embodiment 3

[0183] In Example 1, except having used the following acrylic polymer (a2) instead of the said acrylic polymer (a1), it carried out similarly to Example 1, and produced the adhesive type optical film.

[0184] (Preparation of Acrylic Polymer (a2))

[0185] In a 4-necked flask equipped with a stirring paddle, a thermometer, a nitrogen inlet tube, and a condenser tube, add 100 parts by weight of butyl acrylate (BA), 5 parts by weight of acrylic acid, 0.1 part by weight of 2-hydroxybutyl acrylate, and 0.3 parts by weight as a polymerization The initiator 2,2'-azobisisobutyronitrile and 50 parts by weight of ethyl acetate were slowly stirred while nitrogen gas was introduced to fully replace the nitrogen, and then the liquid temperature in the flask was kept at around 55°C to carry out 8 hours of polymerization reaction to prepare an acrylic polymer (a2) solution. The weight average molecular weight of the said acrylic polymer (a2) was 1.6 million.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap