Pattern defect inspecting method, and pattern defect inspecting device

A defect inspection and patterning technology, which is applied in the direction of measuring devices, optical testing flaws/defects, and photo-plate making process on patterned surfaces, etc., can solve problems such as difficulty in inspecting repeated patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

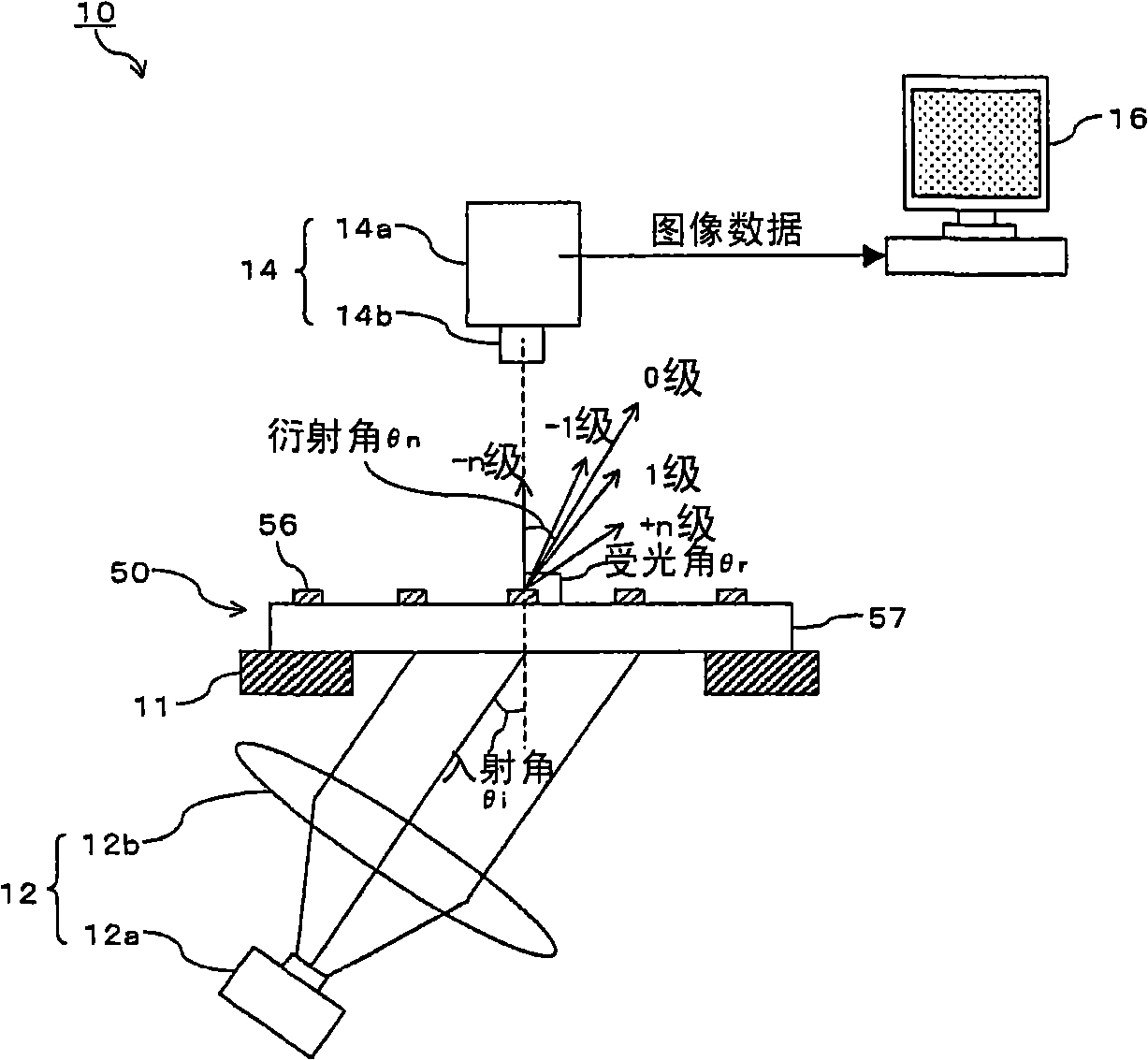

[0036] As described above, Patent Document 1 discloses, for example, using a photomask used in the manufacturing process of a substrate for a semiconductor device having an integrated circuit as an object to be inspected, and inspecting a repetitive pattern generated on the photomask in a short time. method for checking for defects. Here, the problems to be solved by the method disclosed in Patent Document 1 are roughly as follows.

[0037] Conventionally, when the size of a unit pattern of a substrate for a semiconductor device having an integrated circuit is 0.1 μm, it can be checked whether the size variation of the unit pattern is contained within about one-tenth of the size of the unit pattern (that is, about 0.01 μm) within the allowable range. In addition, similarly, when the size of the unit pattern of the photomask used in the manufacturing process of the semiconductor device substrate is 0.4 μm (for example, during the exposure process of 1 / 4), it is also possible t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com