Optimized zoom lens gear wheel drive module and zoom lens using the module

A zoom lens and drive module technology, applied in installation, optics, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

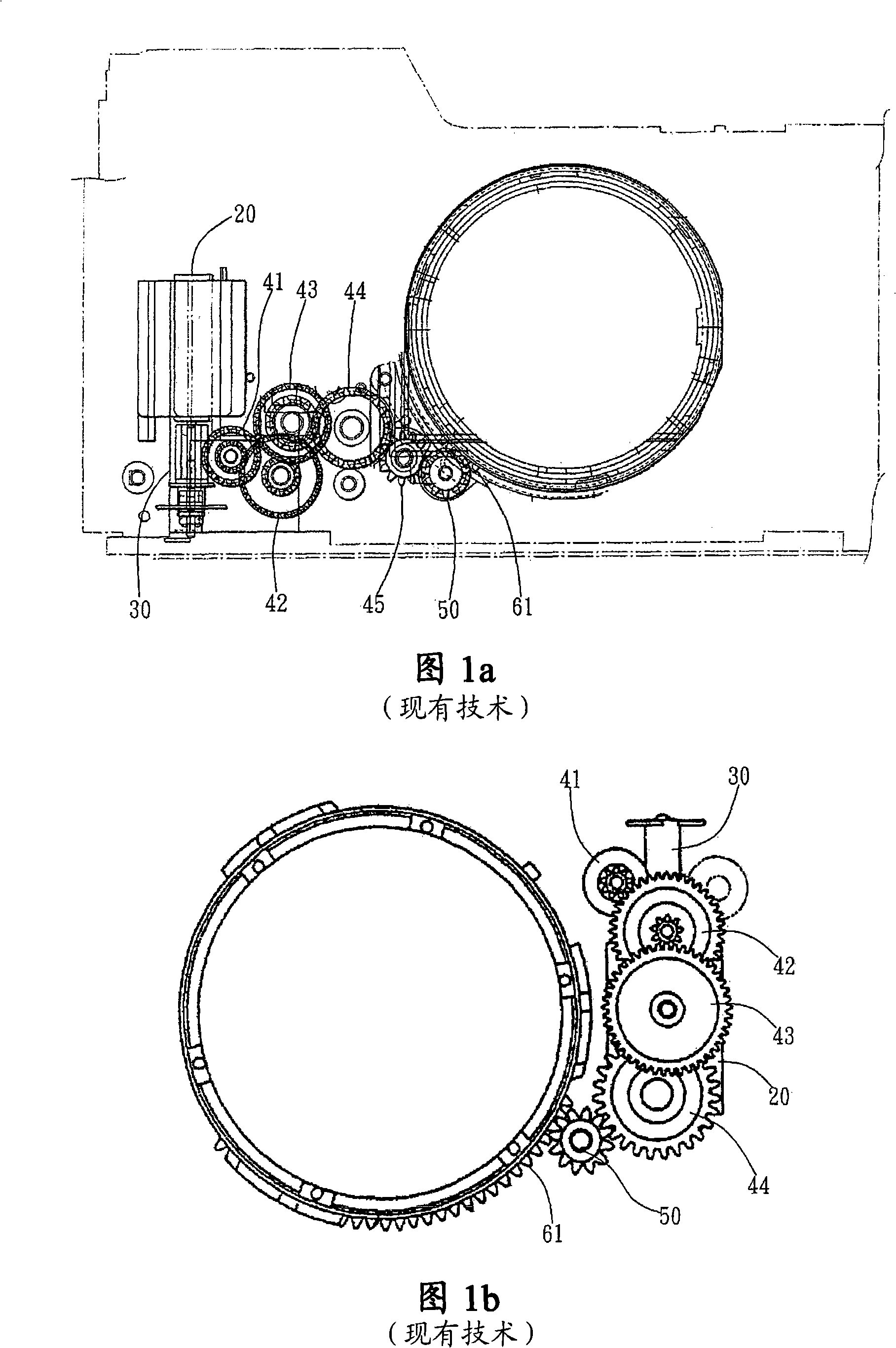

Problems solved by technology

Method used

Image

Examples

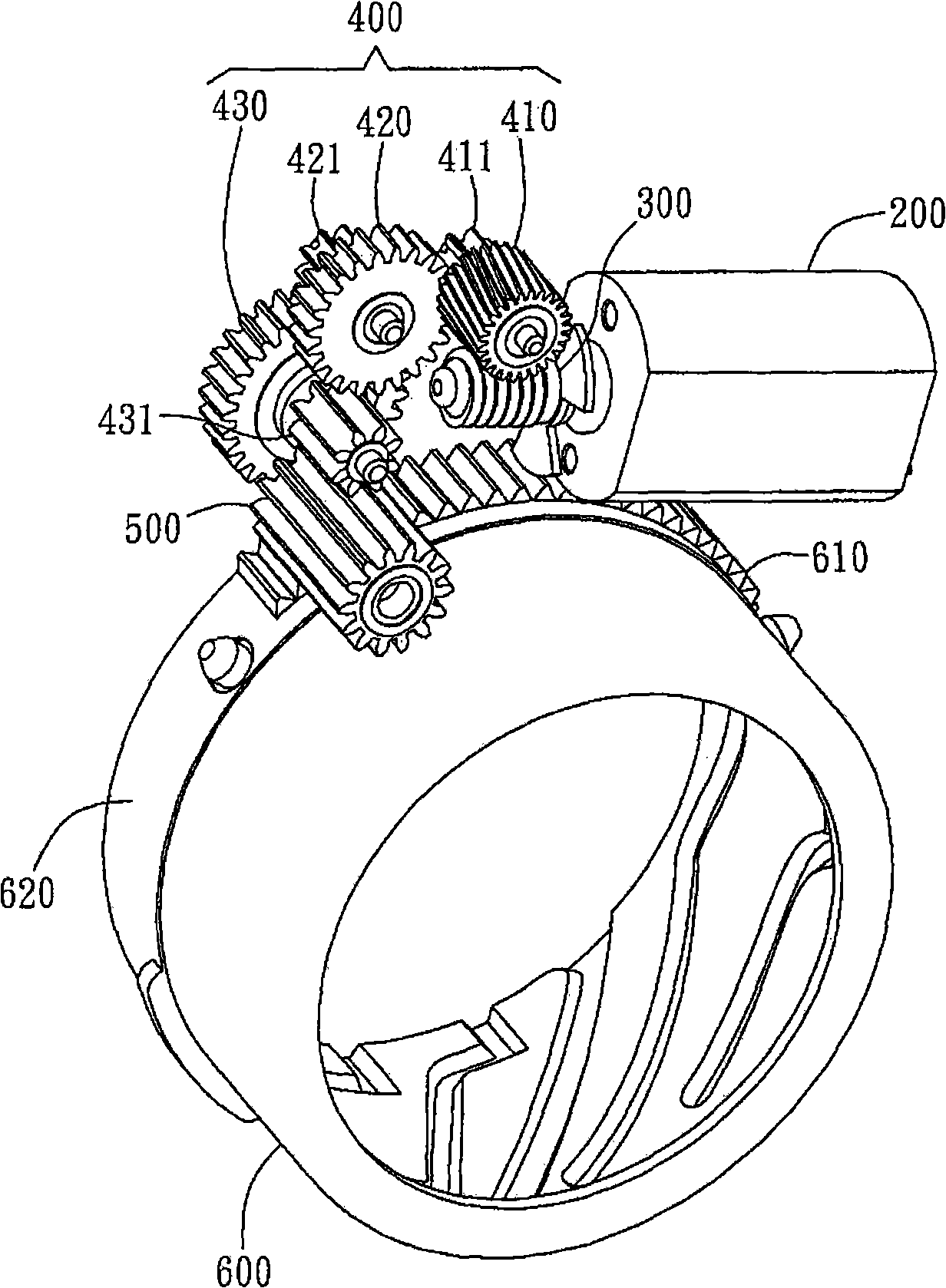

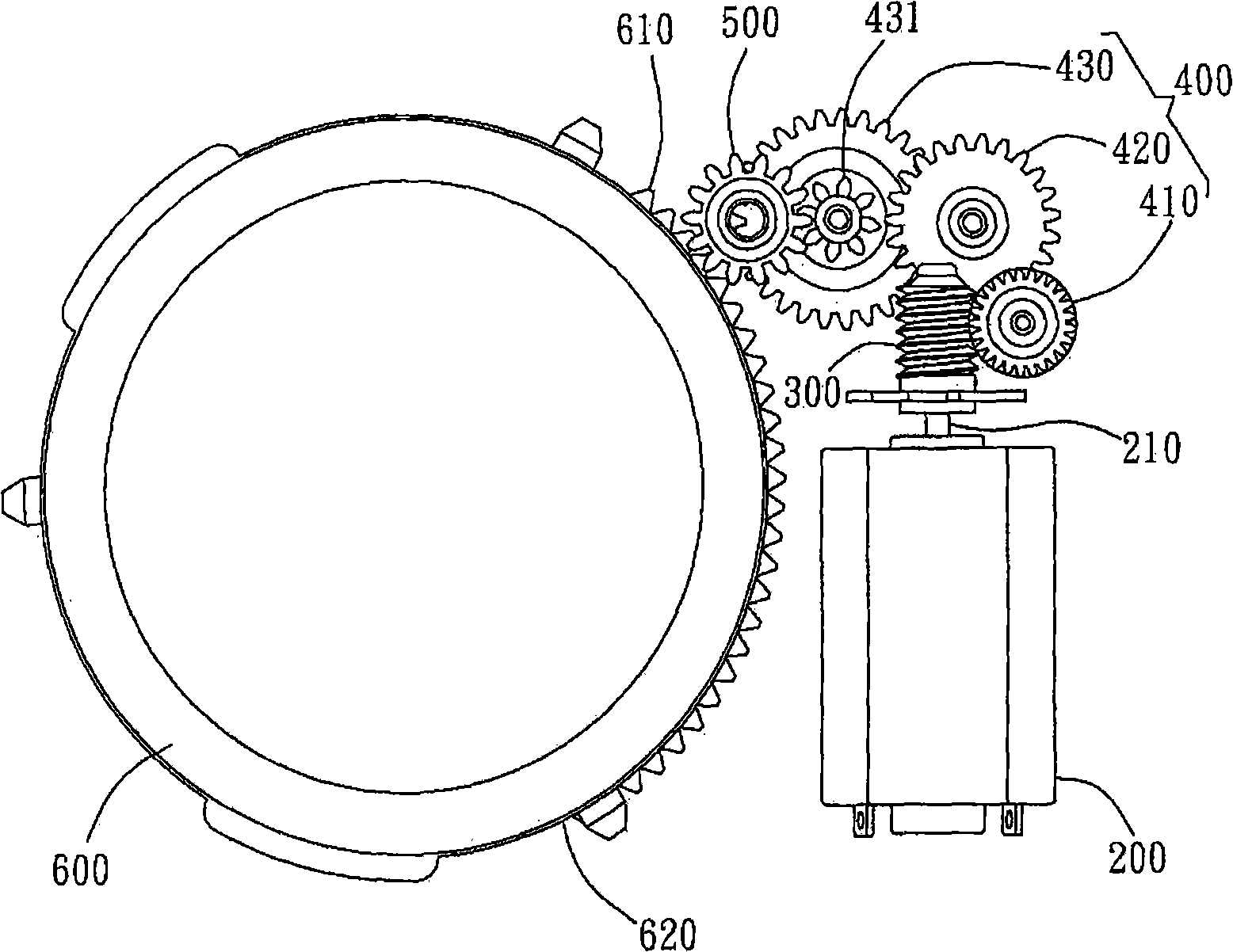

Embodiment Construction

[0031] The present invention provides an optimized zoom lens gear drive module, which uses fewer gear pairs to provide a faster telescopic speed of the lens. The zoom lens gear drive module of the present invention preferably reduces the number of gears in the differential gear set to achieve a faster expansion speed of the zoom lens, and helps implement the design concept of light, thin, short and small modern electronic digital products. The zoom lens gear drive module of the present invention preferably includes three or less differential gears, and provides a faster telescopic speed of the lens under a similar reduction ratio. The zoom lens gear driving module of the present invention is preferably used in a camera equipped with a driving lens barrel, such as a digital camera or a traditional optical camera. However, in different embodiments, the zoom lens gear drive module of the present invention can also be applied to a binocular camera or used in conjunction with other dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com