A glass-metal feedthrough, a method of fabricating it, and an electro-pyrotechnic initiator including it

A glass-to-metal and connector technology, applied in the direction of connection, two-part connection devices, circuits, etc., can solve problems such as the complexity of assembling glass plugs, and achieve the effect of simplifying connection measures and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

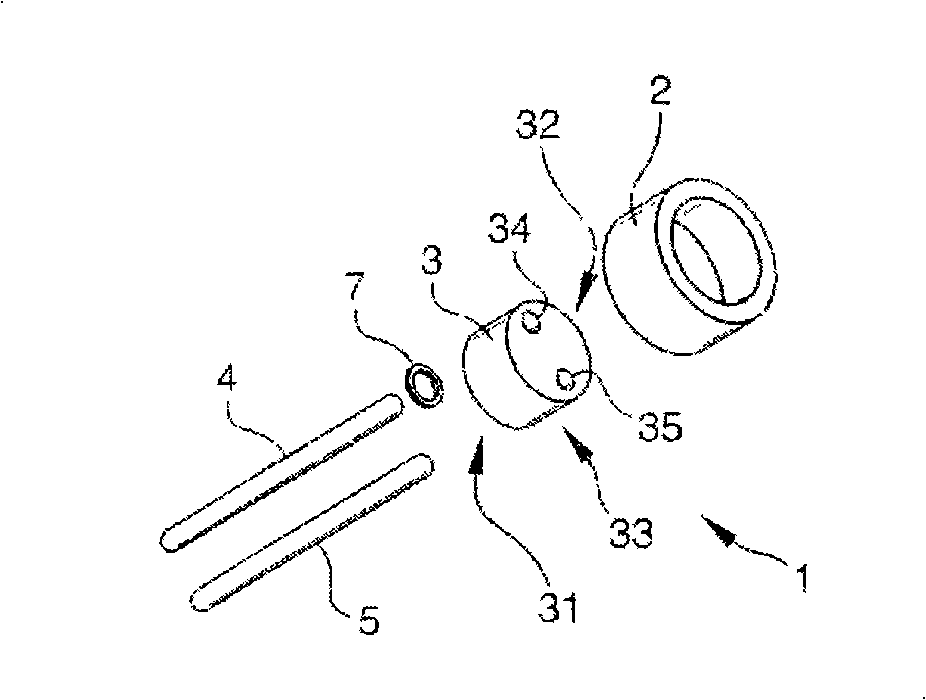

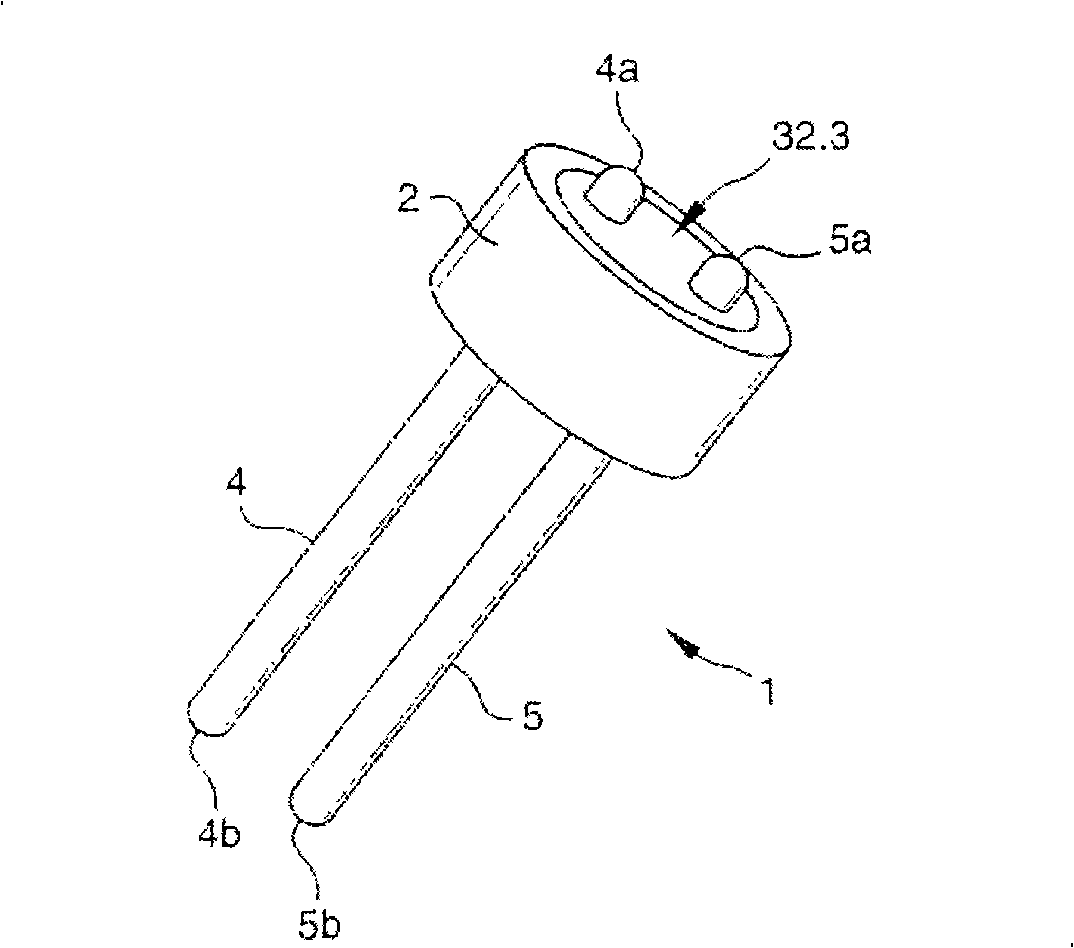

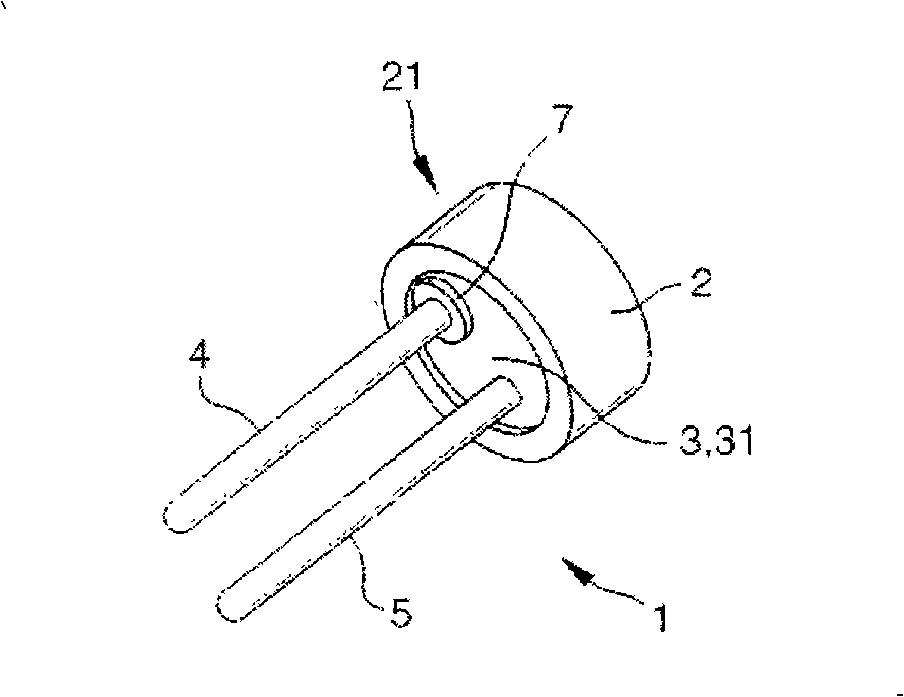

[0028] exist Figure 1 to Figure 3 Among them, an insulating and airtight coaxial glass connector 1 includes an outer metal part 2 surrounding a glass plug 3 in a vacuum-tight manner. For example, the metal part 2 is in the form of a length of circular tube, usually called a metal eyelet. The metal plug has a bottom first face 31 and a top second face 32 remote from the bottom first face 31 . The metal part 2 surrounds the side face 33 of the plug 3 , ie the face that interconnects the first face 31 and the second face 32 . For example, both the metal part 2 and the glass plug have the same height h between the face 31 and the face 32 .

[0029] The plug 3 has two through holes 34 and 35 , each passing from the first side 31 to the second side 32 . Two prongs, namely the first prong 4 and the second prong 5, pass through the holes 34 and 35 respectively in a hermetically sealed manner, each prong having a bottom length protruding from the bottom surface 31 which is longer t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap