Kitchen refuse separator

A sorting device and technology of kitchen waste, applied in classification, solid separation, filtering and screening, etc., can solve the problems of inconvenient equipment installation and movement, large equipment loss, low work efficiency, etc., and achieve simple and reasonable structure, energy saving, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

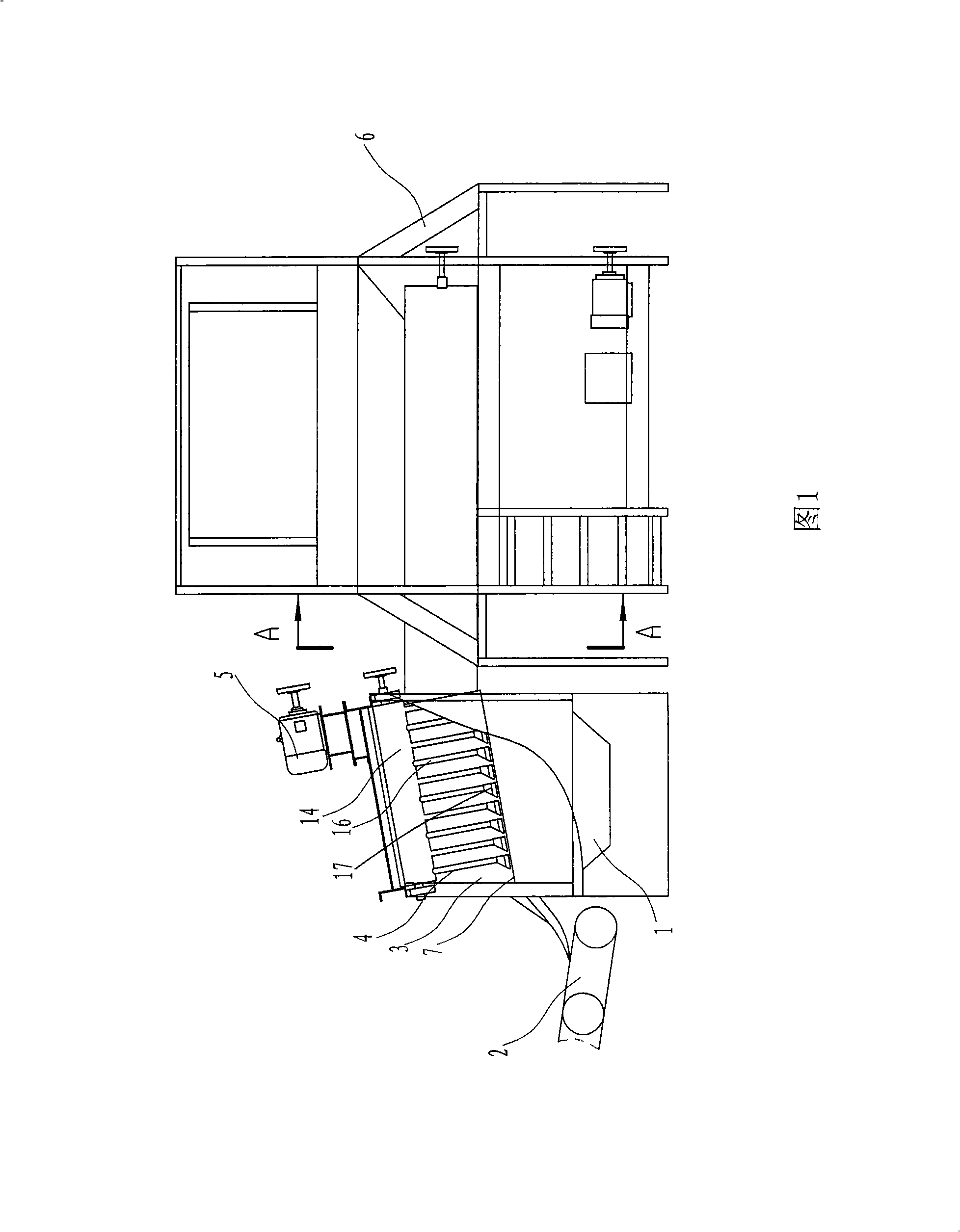

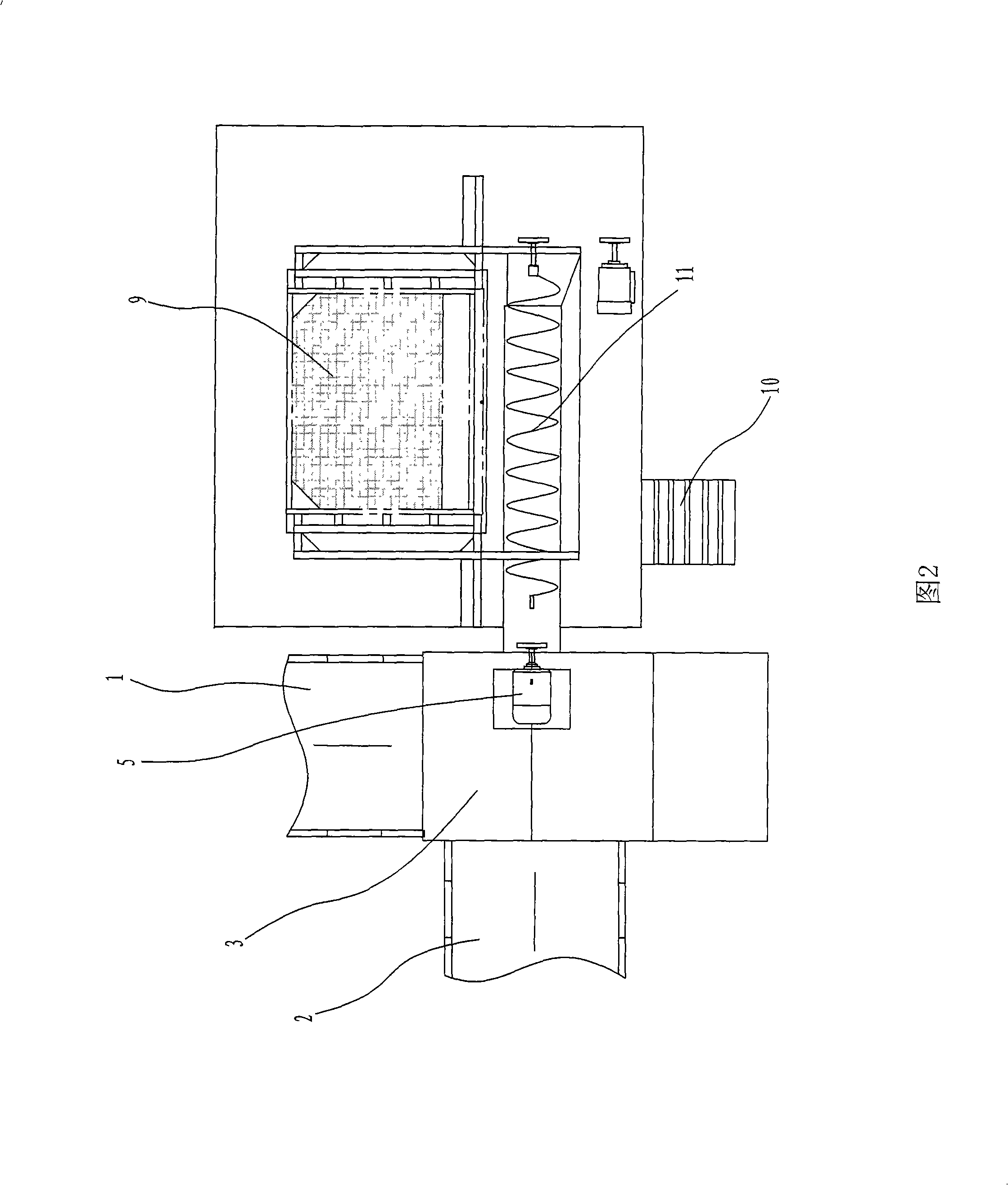

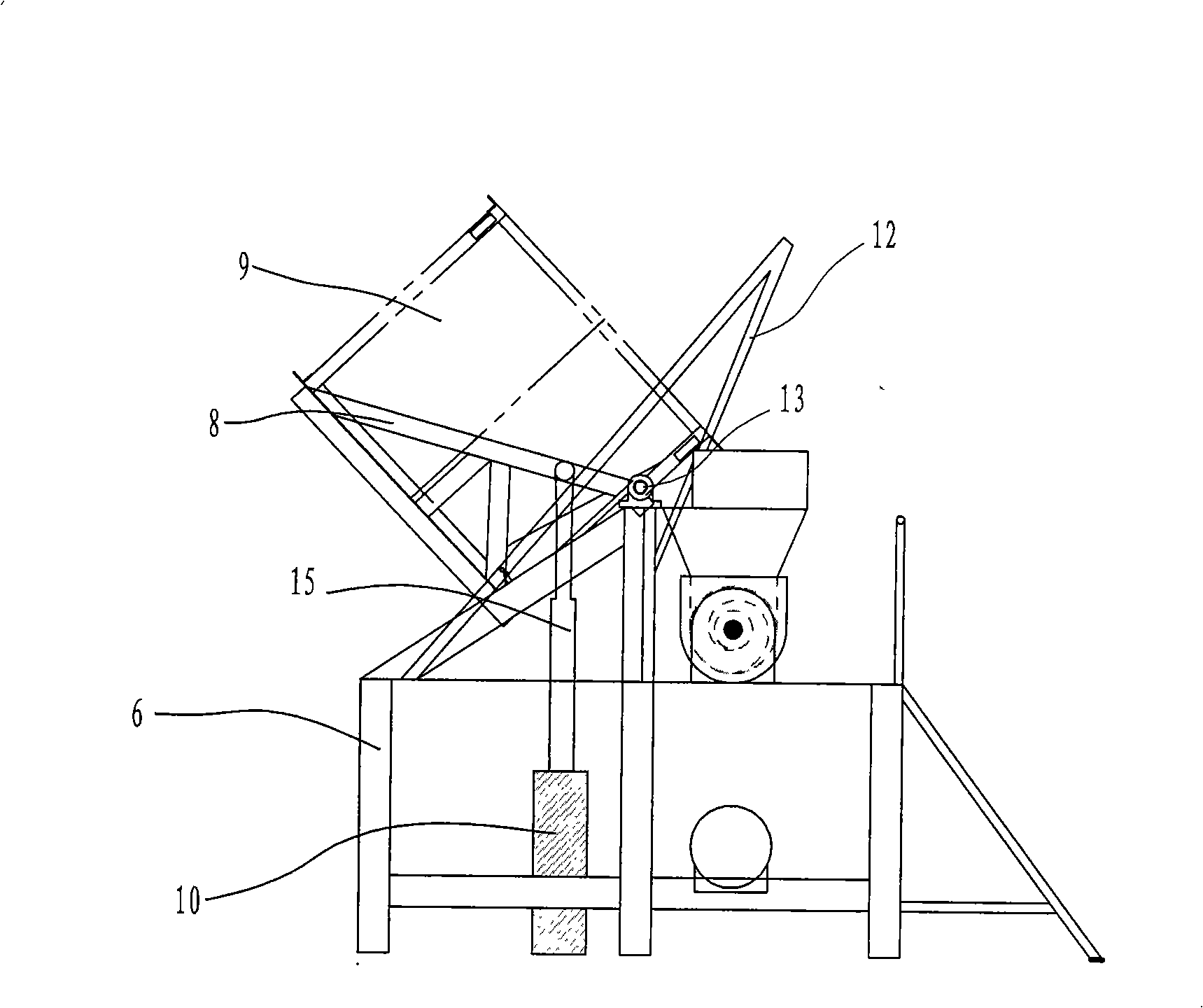

[0017] As shown in Figures 1 to 4, the food waste sorting device is installed on a base 6, which includes a feeding device, a conveying mechanism, a mechanical sorting section and a manual sorting section.

[0018] Wherein, the feeding device includes a hopper 9, a hydraulic cylinder 10 and a turning frame 8, and the hydraulic cylinder 10 and the turning frame 8 constitute a discharge mechanism; the turning frame 8 is arranged below the hopper 9, and it is pivotally connected to the base through a bearing 13 6, the piston rod 15 of the hydraulic cylinder 10 is hinged on the side of the turning frame 8. When sorting garbage, the hopper 9 filled with garbage is placed on the turning frame 8; the piston rod 15 transmits the movement through the turning frame 8 To the hopper 9, the hopper 9 is tipped over and returned to its original position. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com