Forming die of porous flanging stamping procedure and forming method thereof

A technology for forming molds and hole flanging, applied in the field of cold stamping manufacturing, can solve the problems affecting the production efficiency of enterprises, reducing production efficiency, large production equipment and production personnel in workshops, etc., achieving good social and economic benefits, and improving production efficiency. , reduce the effect of means of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

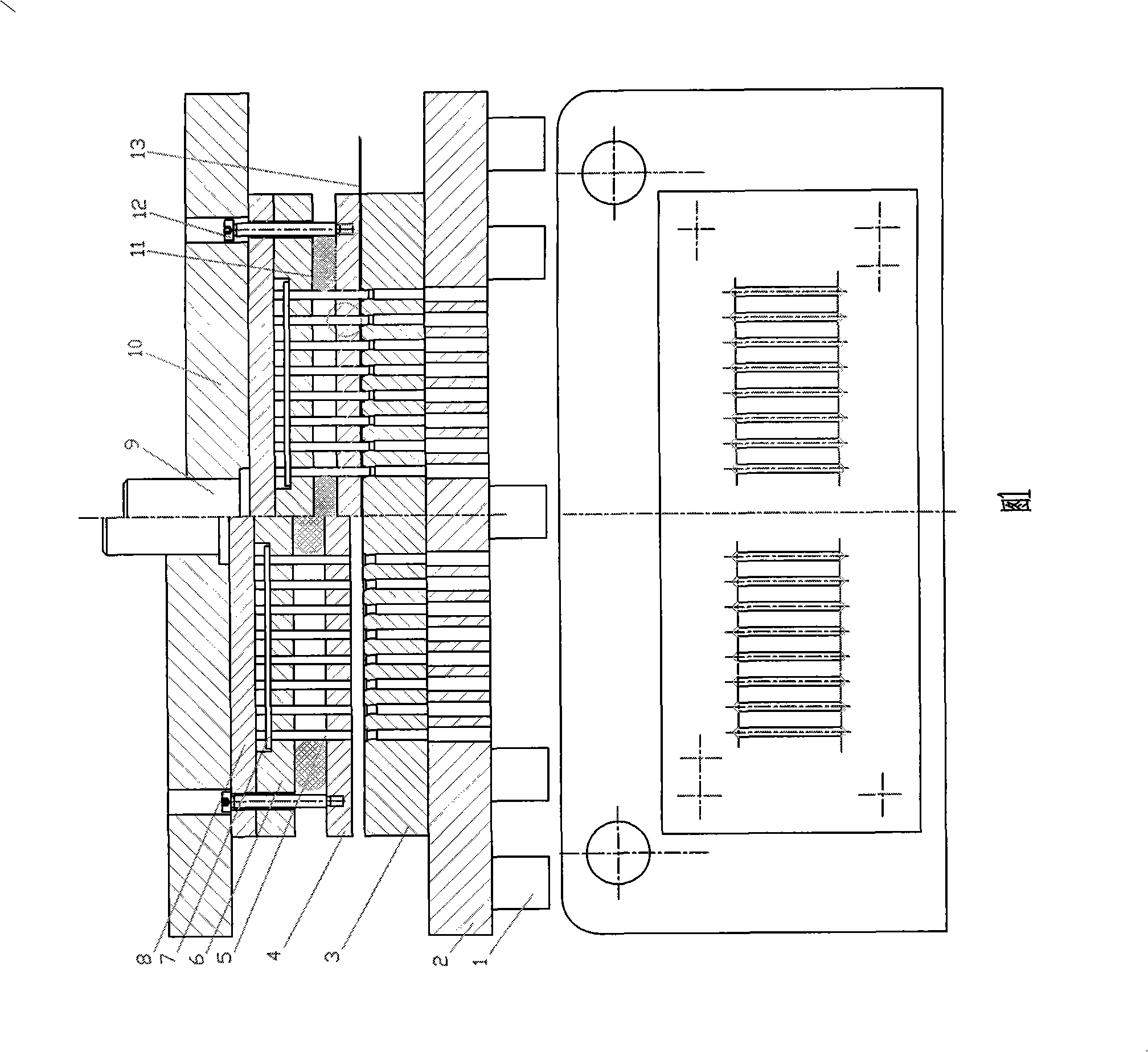

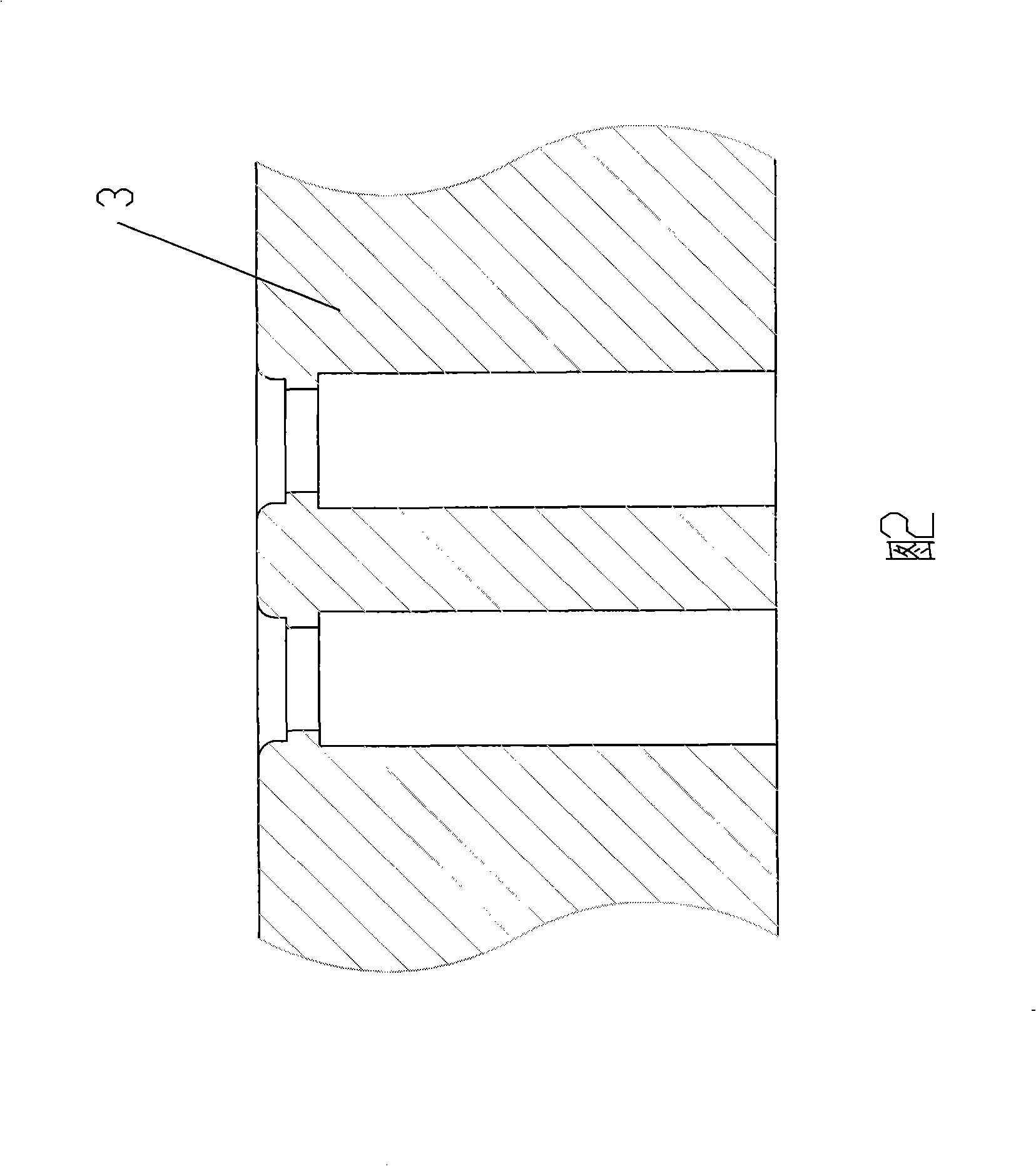

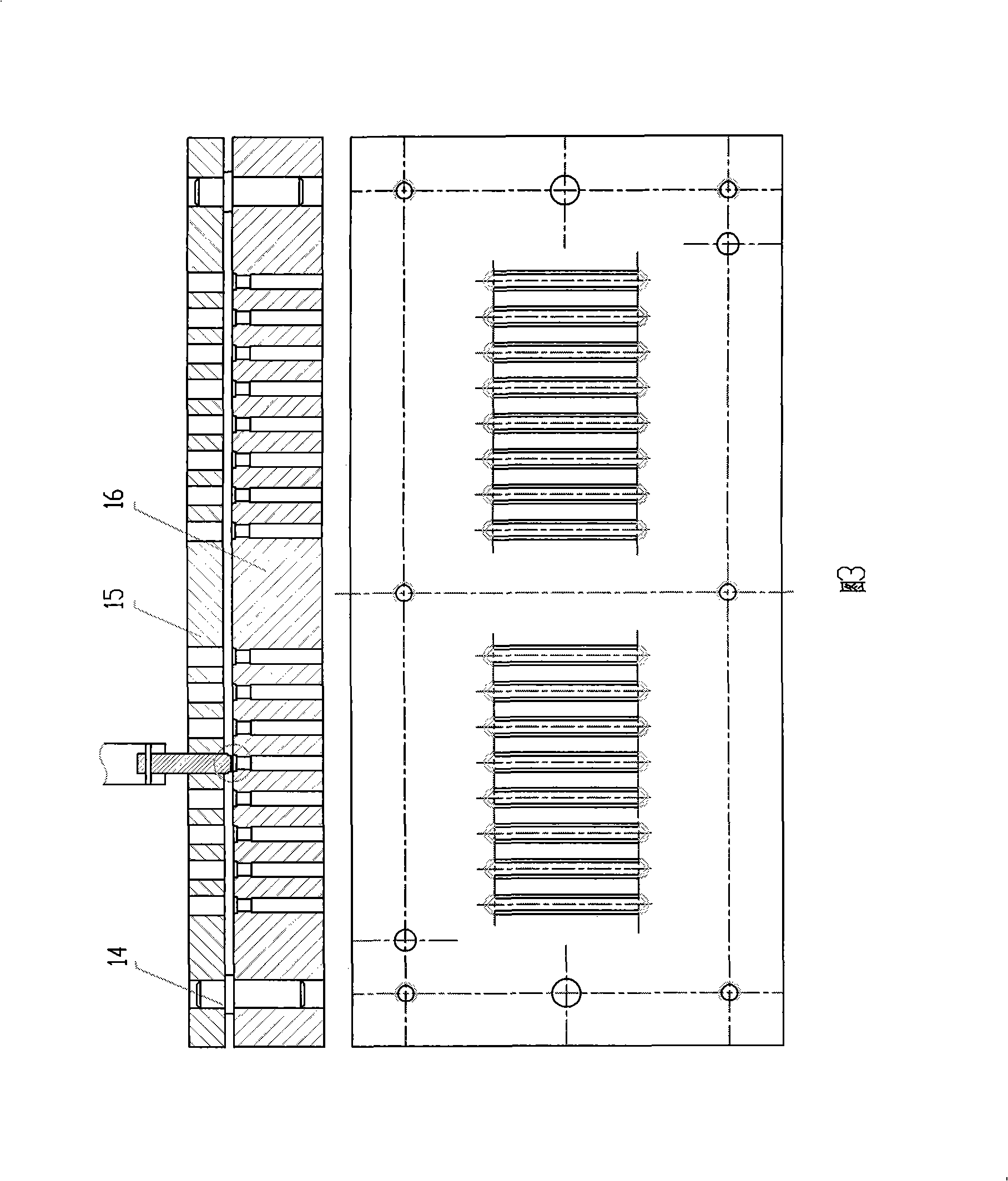

[0019] As shown in Figures 1 and 2, the molding die of the porous flanging stamping process of the present invention includes an upper mold base 10 and a lower mold base 2, and the upper mold base 10 and the lower mold base 2 are assembled by a sliding guide post and a guide sleeve Together, the upper backing plate 8, the upper fixing plate 6 and the upper pressing plate 4 arranged in turn on the bottom surface of the upper die base 10 are assembled together with the upper die base 10 through the pressing screw 12, and the upper surface of the lower die base 2 is provided with The forming die 3 corresponding to the forming punch is provided with a pad iron 1 on the bottom surface of the lower mold base 2 . A polyurethane spring 11 is arranged between the upper fixing plate 6 and the upper pressing plate 4, the die mouth is an arc angle structure, and the bottom of the die is provided with an extruding cutting edge.

[0020] In order to complete the deep-drawing forming process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com