Wrench display setting device

A technology for setting devices and wrenches, which is applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., and can solve problems such as increasing complexity and difficulty, being unusable, and affecting settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

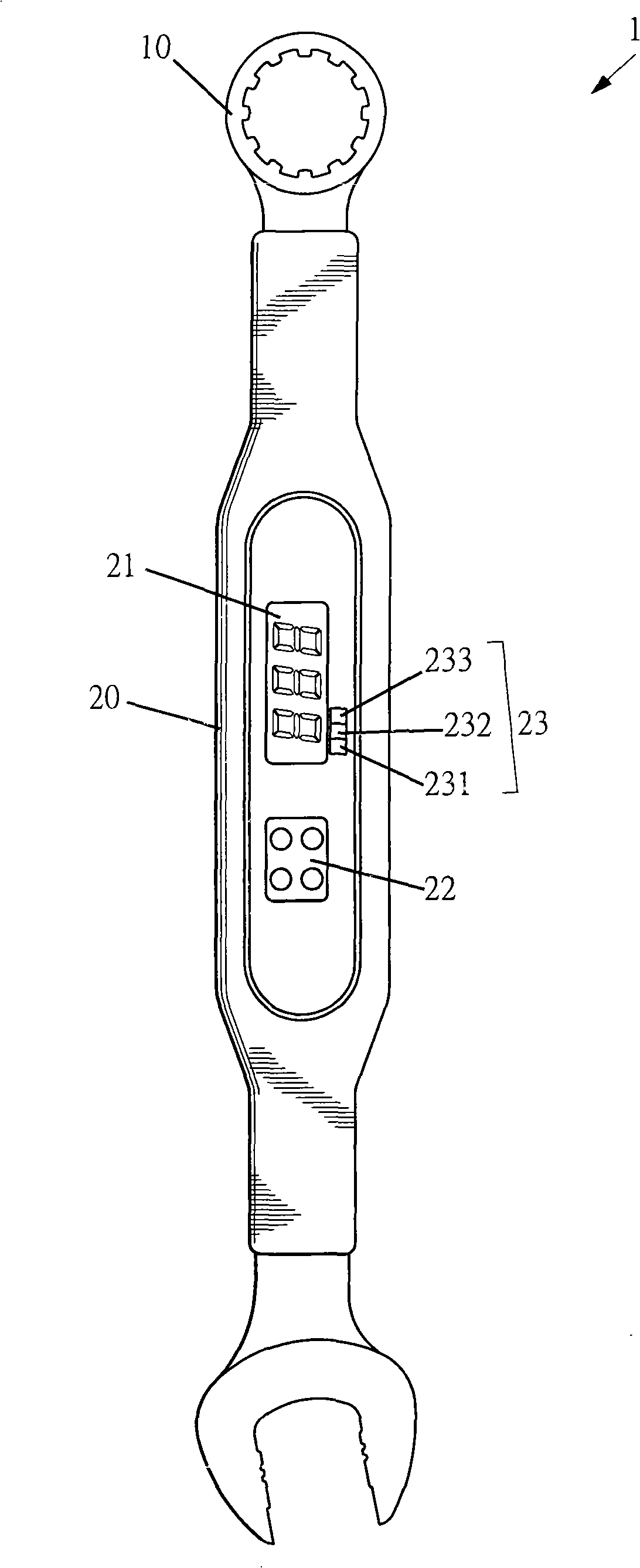

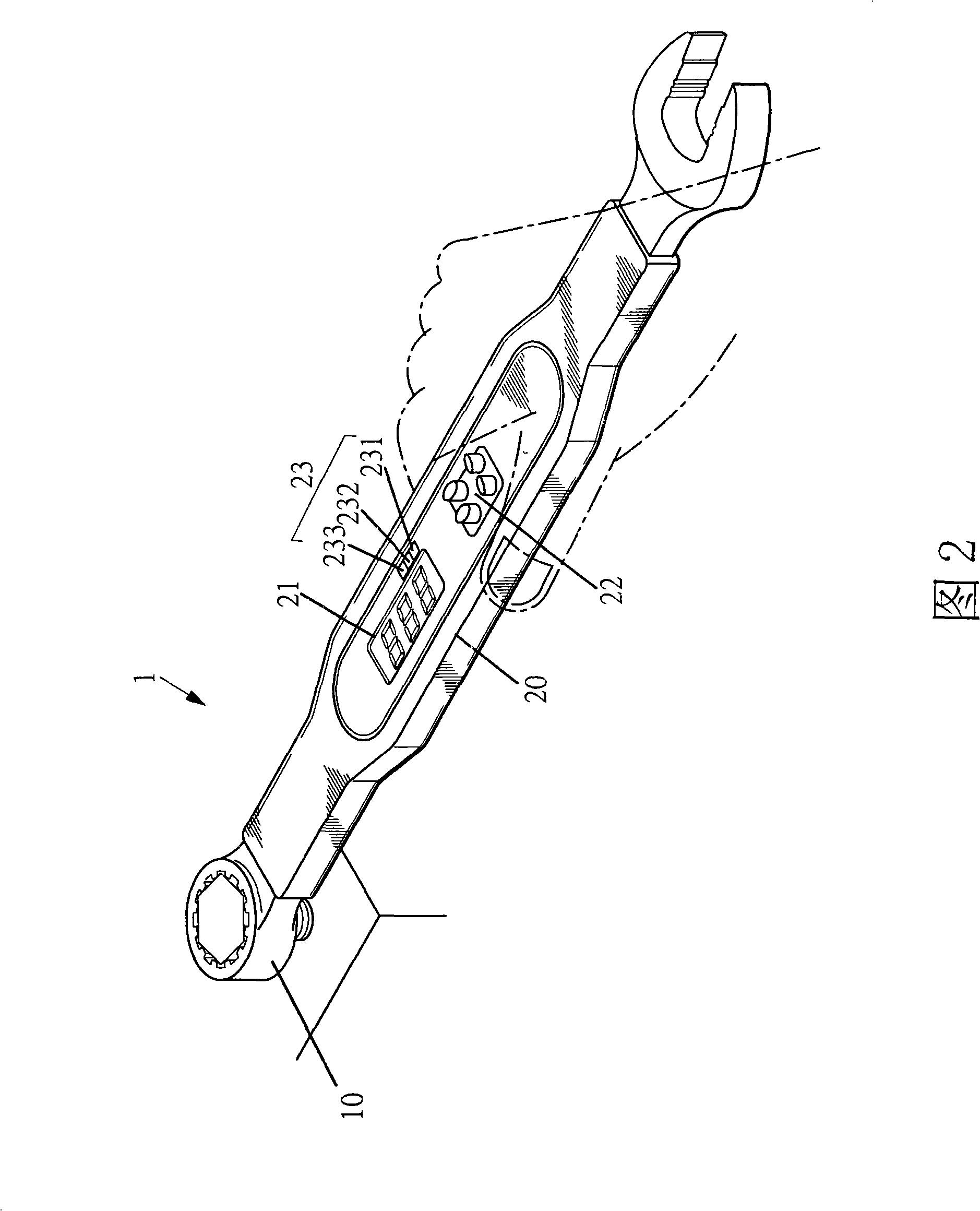

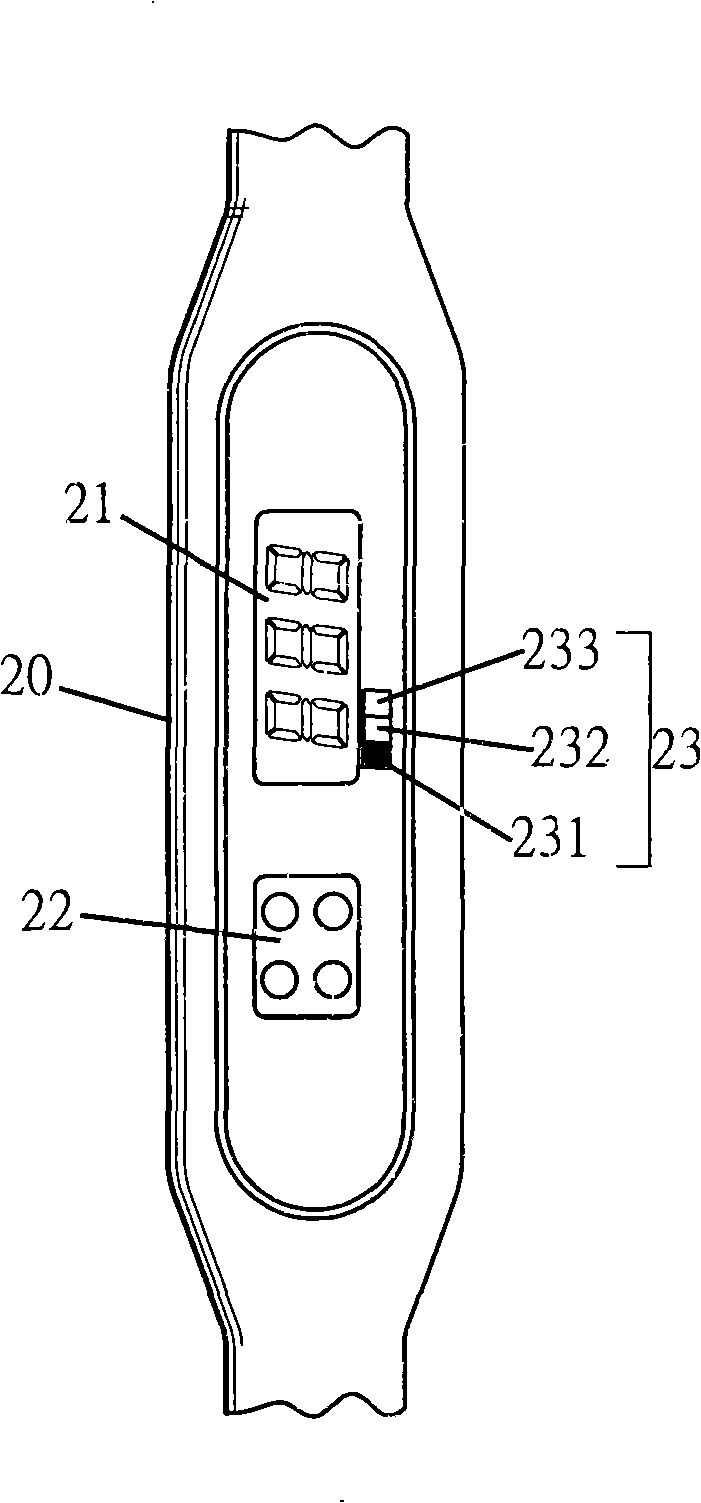

[0020] The present invention relates to a wrench display setting device, its composition structure, refer to figure 1 As shown, a driving part 10 is provided at both ends of the main body 1 respectively. In the embodiment of the present invention, a torx trigger head and an open trigger head are exemplified. A processing and display part 21 is arranged on the side, and a control part 22 is arranged below the processing and display part 21 in the grip part 20, and an adjustment part 23 is arranged on the side adjacent to the processing and display part 21; wherein:

[0021] The processing and display part 21 can receive and process the setting signals of the control part 22 and the adjustment part 23, and display the processing or setting results on the main body 1; the control part 22 can set and control the processing and display part 21 The opening and closing of the torque, the zero correction of the torque, the adjustment of the preset torque value range, and the functions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com