Clip-type conveying belt and cleaner

A conveyor belt and sheet technology, applied in the field of sheet conveyor belts and cleaning devices, can solve problems such as easy blockage of the mesh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

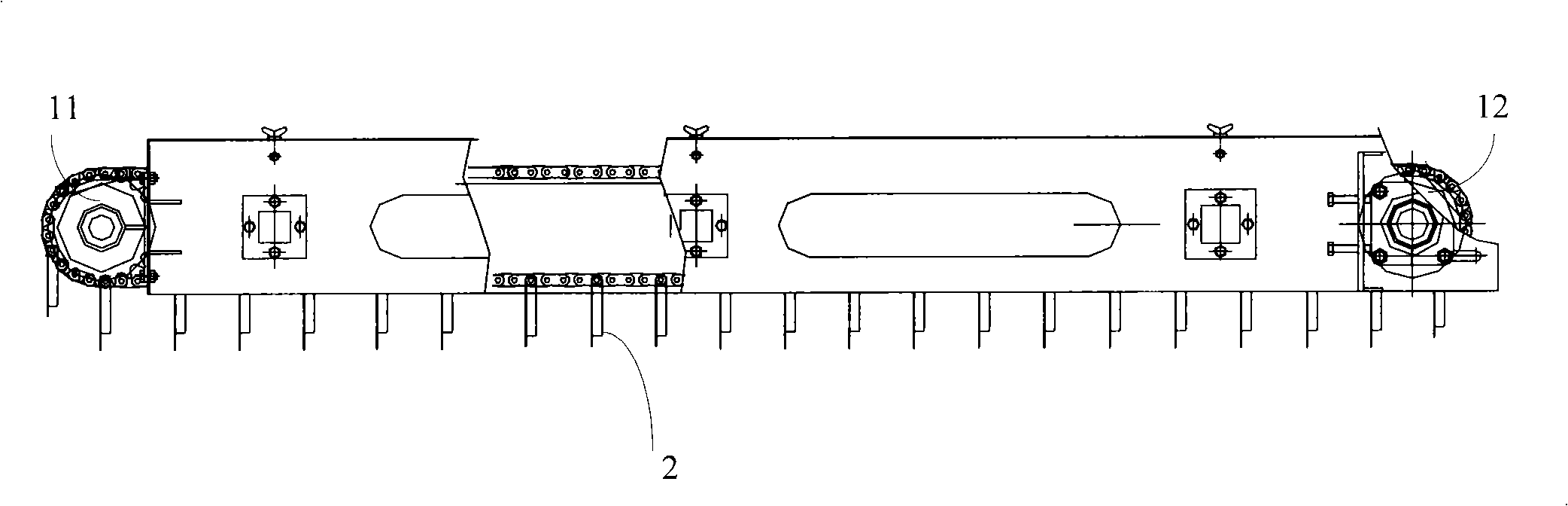

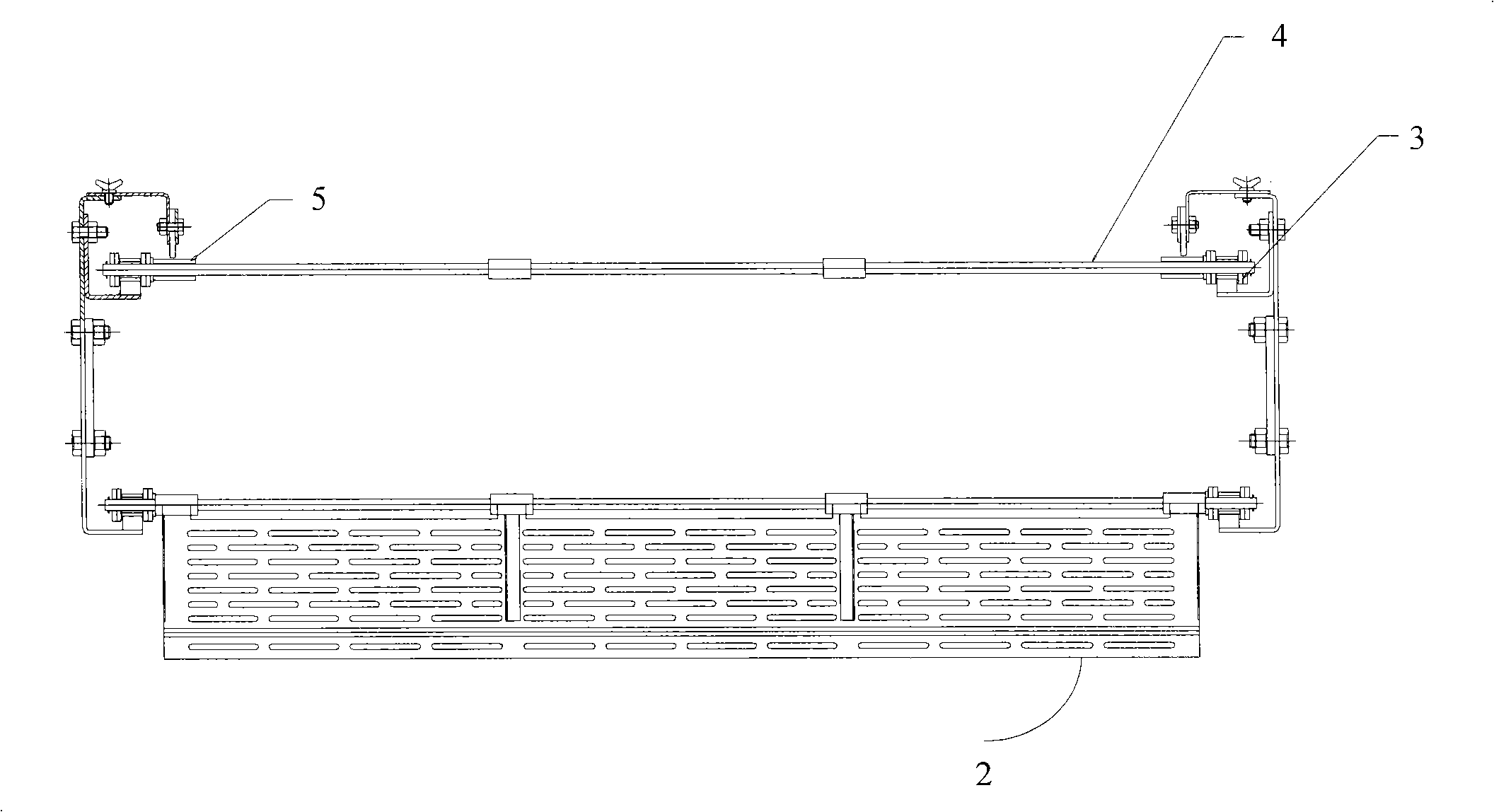

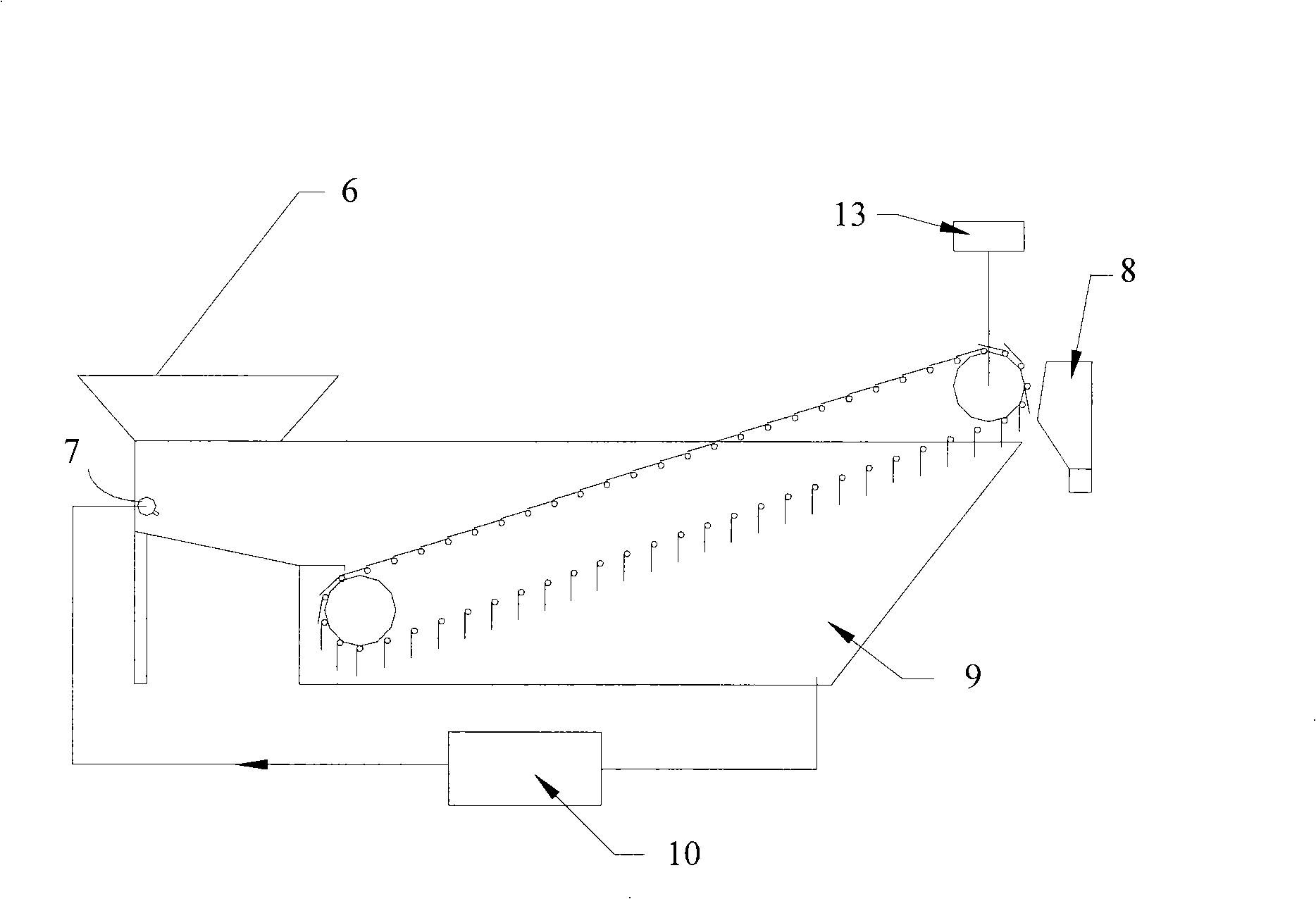

[0016] Referring to Fig. 1, as shown in the figure, the mesh type chain plate 2 with the strip filter hole is hinged on the roller chain pin shaft. The driving wheel 11 drives the conveyor belt through the chain drive to convey forward. On the upper layer of the sheet conveyor belt, the mesh-type chain plates 2 are overlapped together in a fish-scale manner to form an approximate strip-shaped mesh surface, and the conveyor belt is in a "closed" state. The material is conveyed on the "net surface" and slides down to the driven wheel 12. To the lower layer of the conveyor belt, the mesh type chain plate 2 is suspended on the pin shaft of the roller chain due to gravity, and the conveyor belt is in an "open" state. Liquids containing dirt can leave the conveyor belt without proble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com