Surface coated silastic bulb and its manufacturing method

A manufacturing method and technology of silicone rubber, applied in the direction of loss prevention measures of lighting devices, lighting devices, lighting and heating equipment, etc., can solve the problem of unsafe broken glass pieces, achieve soft and uniform lighting, improve safety, and improve transparency. Effects of Light Rate and Diffuse Scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

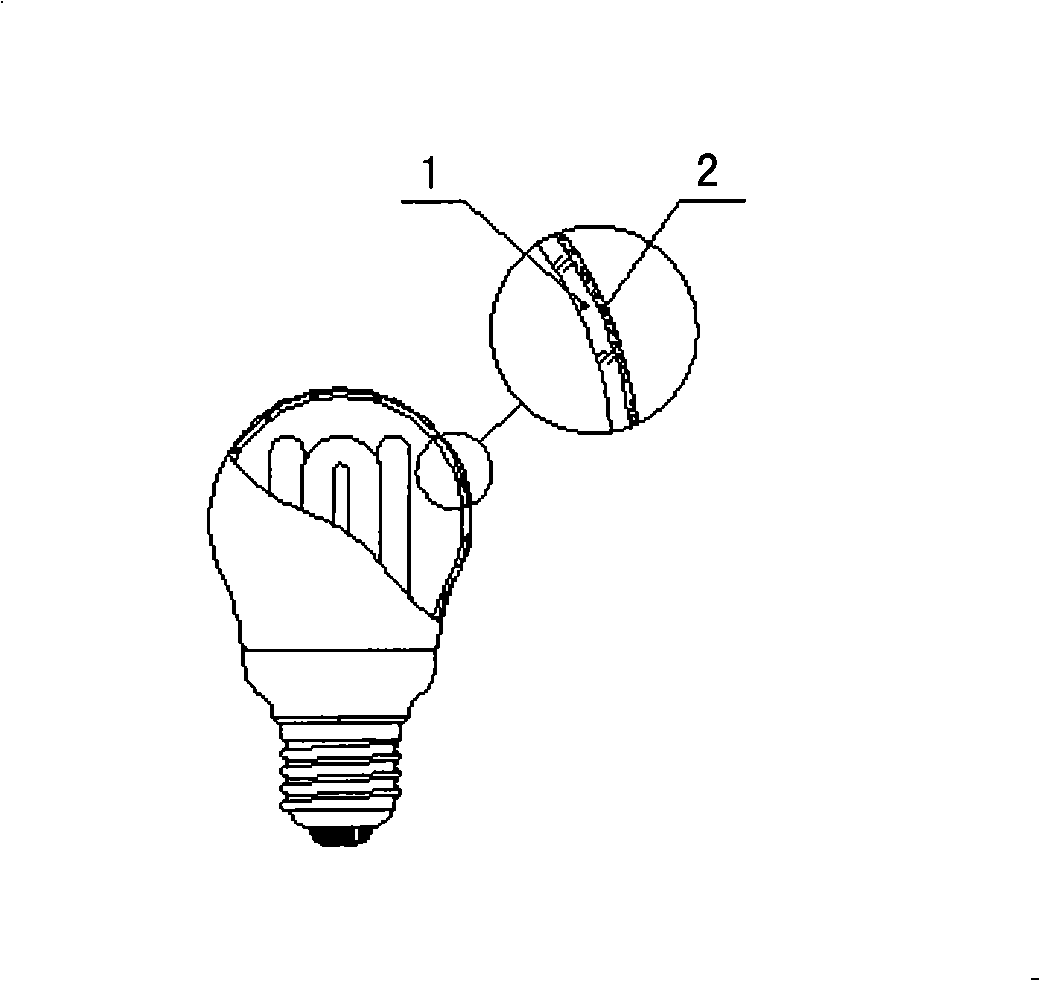

[0018] Such as figure 1 As shown, the light bulb of the present invention includes a glass bulb 1 and a film layer 2 . The film layer 2 is evenly applied to the bulb 1 . In one embodiment, the film layer is made of silicone rubber. Of course, in other embodiments, other materials can also be selected, as long as the material has good light transmittance and diffuse scattering to make the light emitted by the film layer softer and more uniform, and the material should also be compatible with the light bulb. The material adheres well so that glass shards do not fly when the bulb shatters.

[0019] In addition, white or colored filling substances can be added to the film layer material to make the bulb have various color effects.

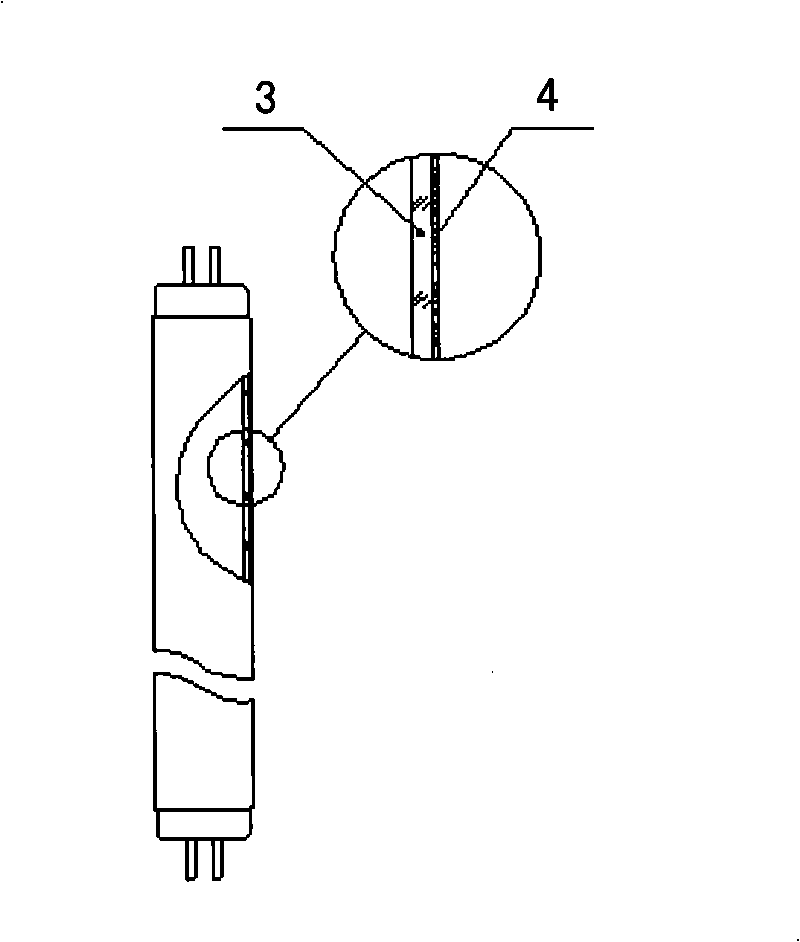

[0020] figure 2 A further embodiment of the invention is shown, in which the film layer 4 is applied to the bulb 3 of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com