Matrix type dielectric water-cooling resistor locker

A water-cooled resistor, matrix technology, applied in resistors, resistor components, circuits, etc., can solve problems such as volume reduction, and achieve the effect of volume reduction, small footprint, and balanced cooling effect

Active Publication Date: 2008-11-19

BEIJING 718 YOUSHENG ELECTRONICS

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to overcome the disadvantages of the original water-cooled resistors that the cooling water is electrified and that it is not convenient to assemble into super-large-scale water-cooled resistors, the present invention introduces a water-cooled resistor, which can realize high-voltage insulation between the cooling water and the resistor, and remove the sealing groove at the same time. Numerous resistor cores are compactly assembled together, the structure is simple, and the volume is greatly reduced

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

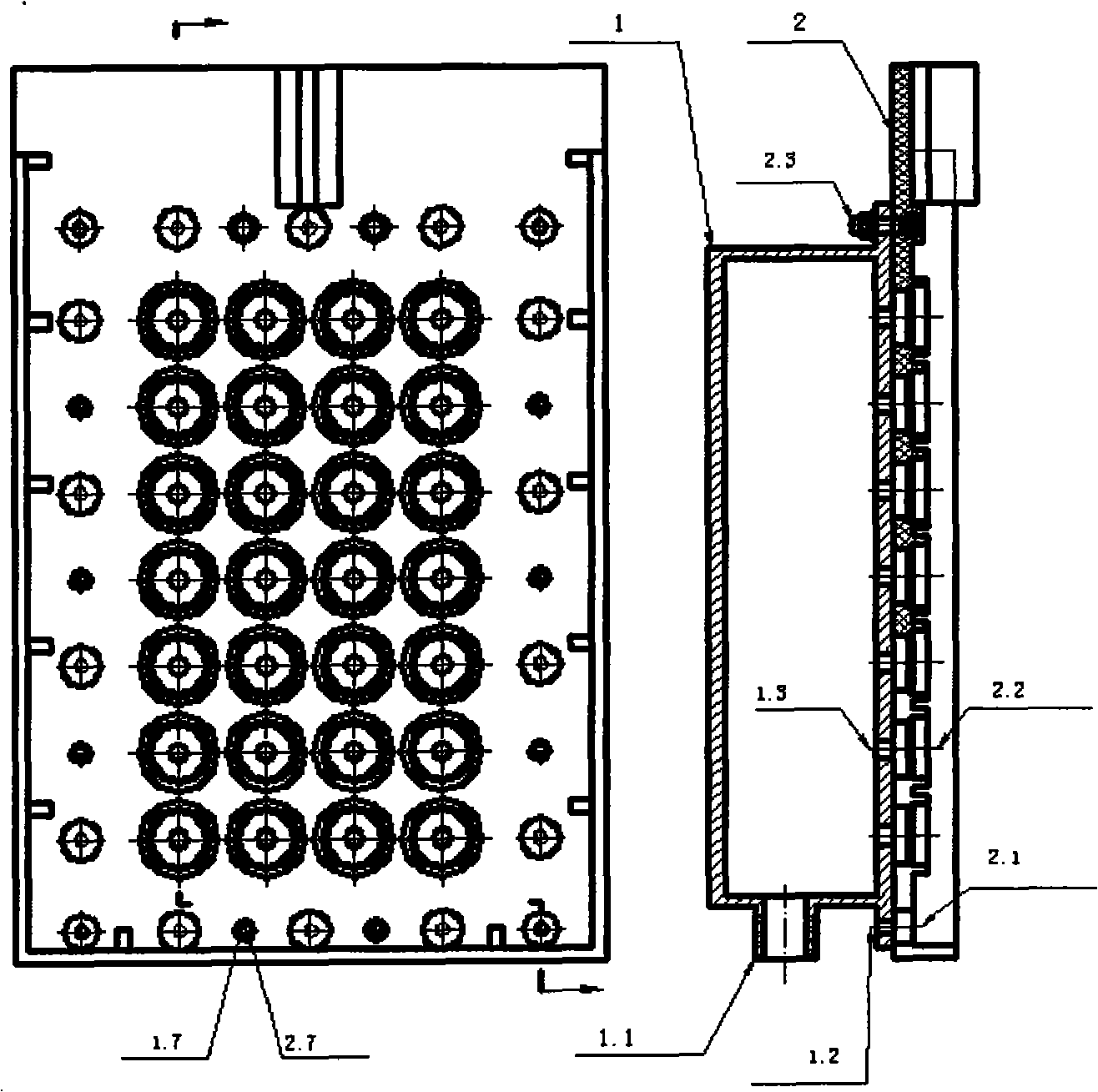

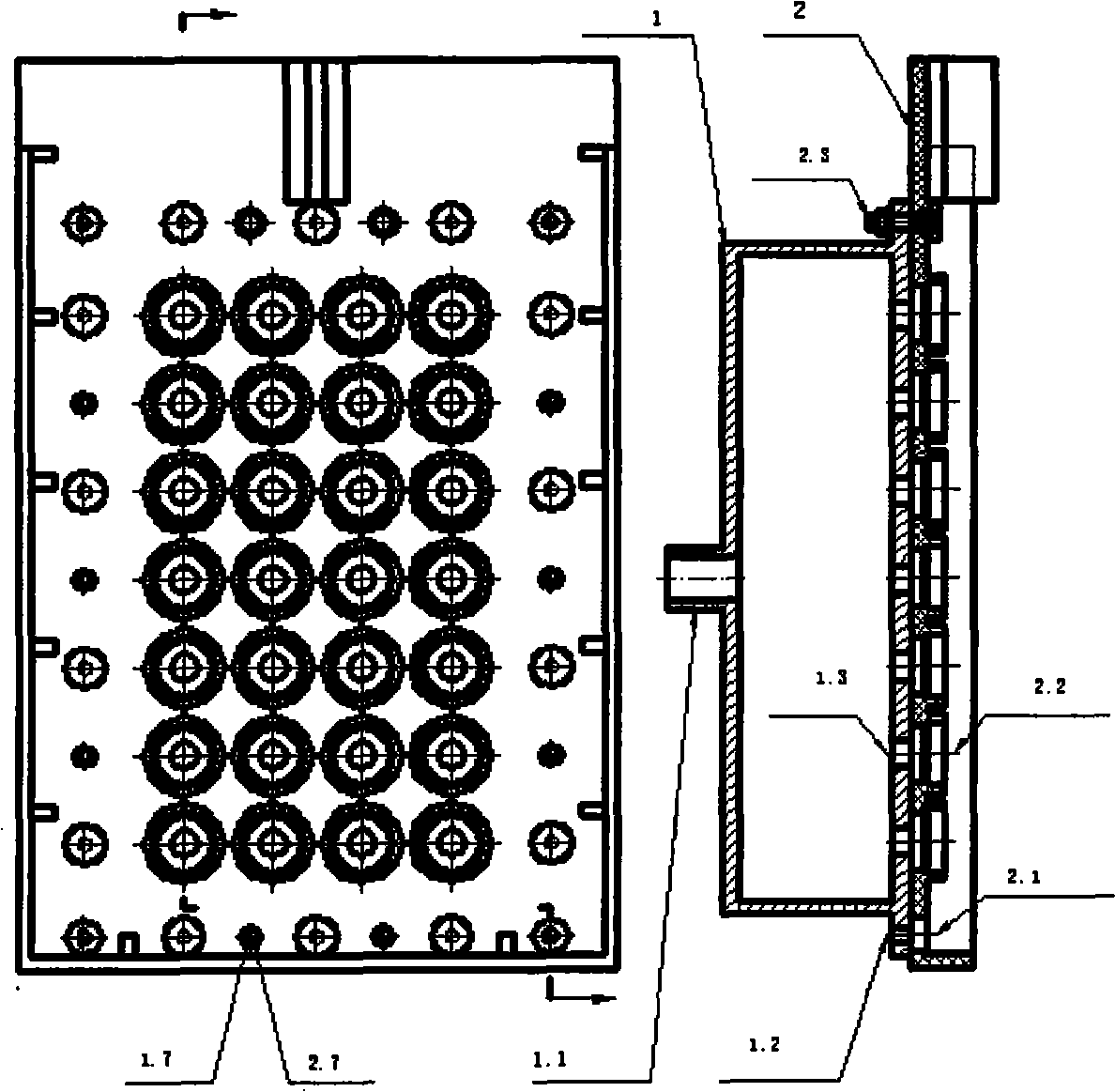

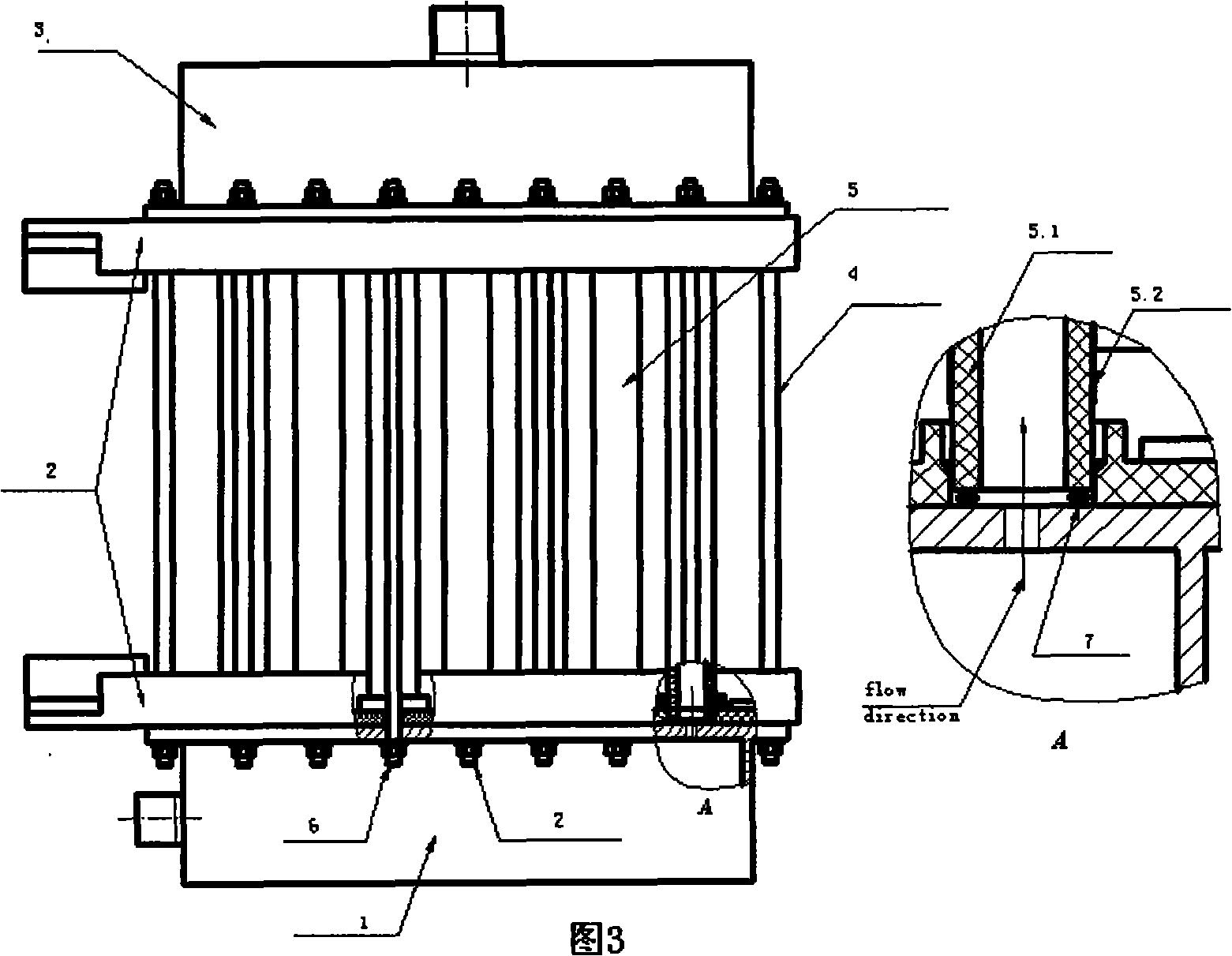

Disclosed is a matrix form insulated water-cooling resistor which is characterized in that a gasket ring locating plate is fixed on the sealed plane of a splitter box and a header tank, and a gasket ring is laid in a hole of the gasket ring locating plate; the splitter box is arranged below the header tank, with the self sealing plane of the splitter box facing upwards and the self sealing plane of the header tank facing downwards; tens of resistor cores are arranged in the form of a matrix between the splitter box and the header tank and are fixed through screws, contour locating rods and worms and are installed and sealed integral. The resistor cores take hollow porcelain tubes as base bodies, and the porcelain tubes are equal in height, with both ends be parallel planes perpendicular to the axis. Conducive films are arranged on the outer walls of the porcelain tubes and the internal holes of the porcelain tubes are water passages; cooling water and conductive films are separated by the walls of the porcelain tubes. The insulated water-cooling resistor is high in cooling efficiency, and the cooling water and the resistor can be insulated at high voltage. The insulated water-cooling resistor is compact in structure and is convenient to be assembled into a super-power matrix form insulated water-cooling resistor.

Description

Matrix insulated water-cooled resistance cabinet Technical field The invention belongs to the field of water cooling resistors. Background technique The original water-cooled resistors are cooled by direct contact between the cooling water and the resistors. Since the cooling water is in direct contact with the resistors, the cooling water is charged, and there are great safety hazards in use (especially in high-voltage circuits. middle), and it is not allowed in some circuits; on the other hand, the original water-cooled resistor uses the sealing ring squeezed in the sealing groove to realize positioning and sealing water. This structure is complex and bulky after assembly. It is not convenient to assemble into super-power water-cooled resistors. Contents of the invention In order to overcome the disadvantages of the original water-cooled resistors that the cooling water is electrified and that it is not convenient to assemble into super-large-scale water-cooled resis...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01C1/082

Inventor 李本德唐海岩周向辉

Owner BEIJING 718 YOUSHENG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com