Position Feedback Master Hand System of Live Repair Robot

A robot, master-hand technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as the limitation of robot operation content and operation efficiency, the inability of the operator to perceive the working environment, and the inability to achieve master-slave control, so as to improve the operation Efficiency, increased flexibility, easy wiring effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

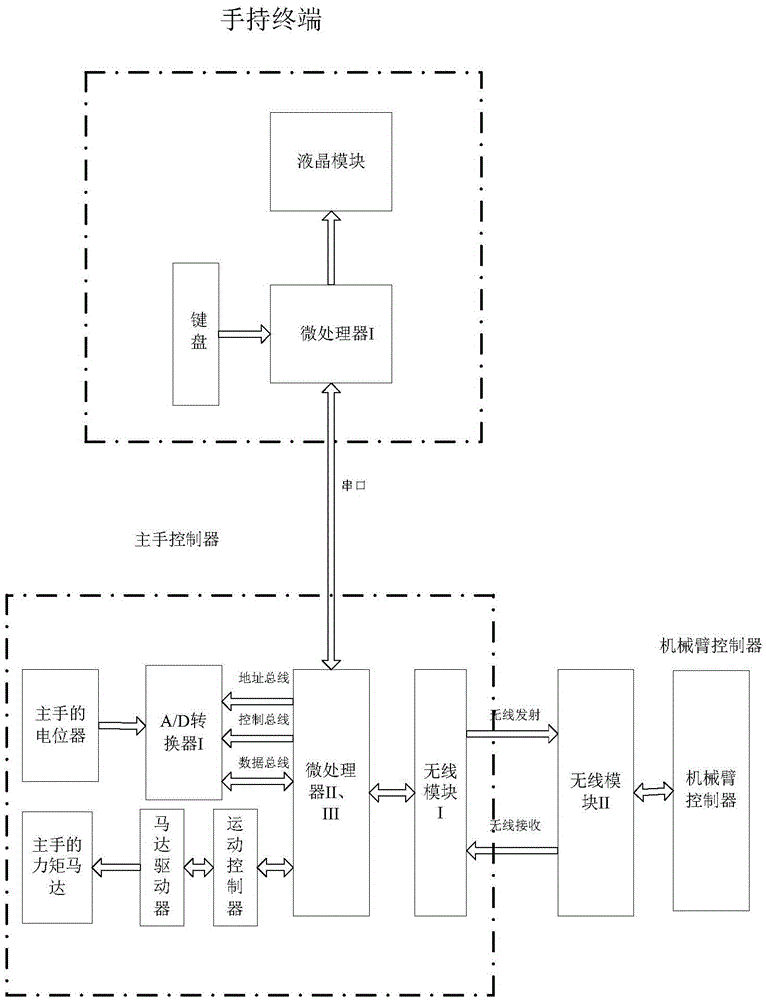

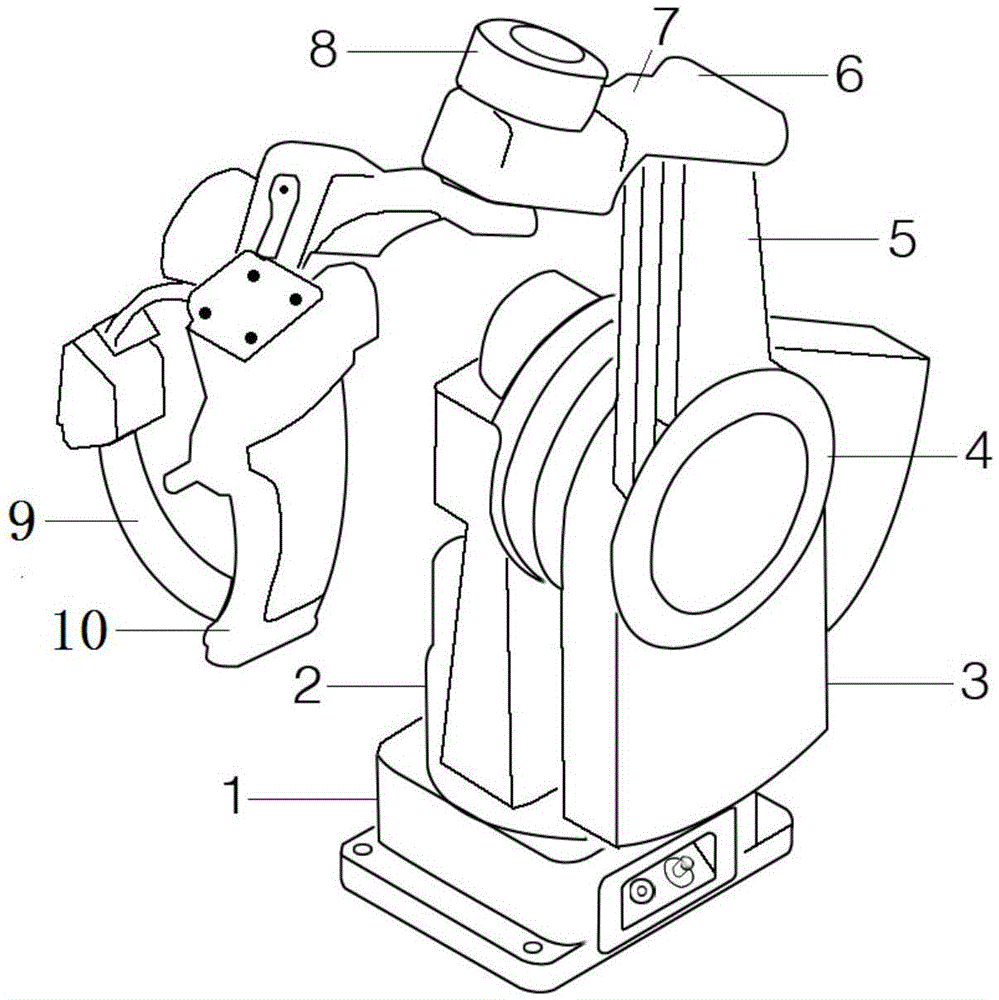

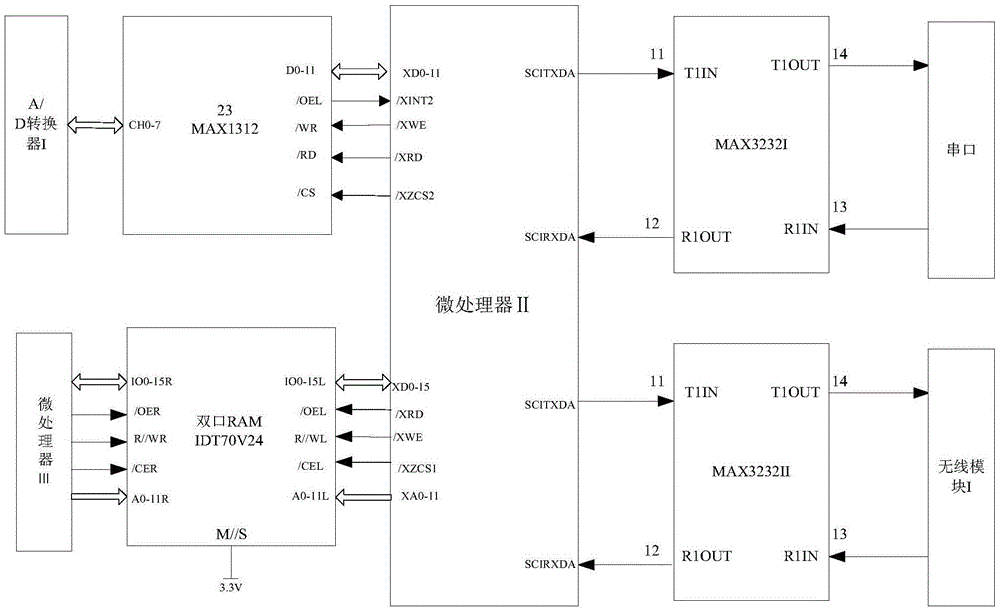

[0042] figure 1 Among them, a live repair robot position feedback main hand system, its handheld terminal includes a microprocessor I, which is connected to the keyboard, LCD screen and the main hand controller respectively; the main hand controller uses a DSP chip, including a microprocessor II And the microprocessor III, the microprocessor II is connected with the microprocessor I and the dual-port RAM respectively, and the dual-port RAM is connected with the microprocessor III; the microprocessor III is connected with the motion controller respectively, and the motion controller is connected with the motor driver , the motor driver is connected with the torque motor 2 of the main hand; the A / D converter I is connected with several potentiometers (at each joint movement axis) of the main hand, and the microprocessor II is connected with the A / D conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com