Three-dimensional interposed waveguide type medium pool for Brillonin amplifying laser serial beam combination

A technology of dielectric cell and beam grouping, applied in laser parts, optics, nonlinear optics, etc., can solve the problems of difficulty in beam entrance and exit, and difficulty in good cross-overlap, so as to increase the interaction length, improve the energy conversion efficiency, Adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

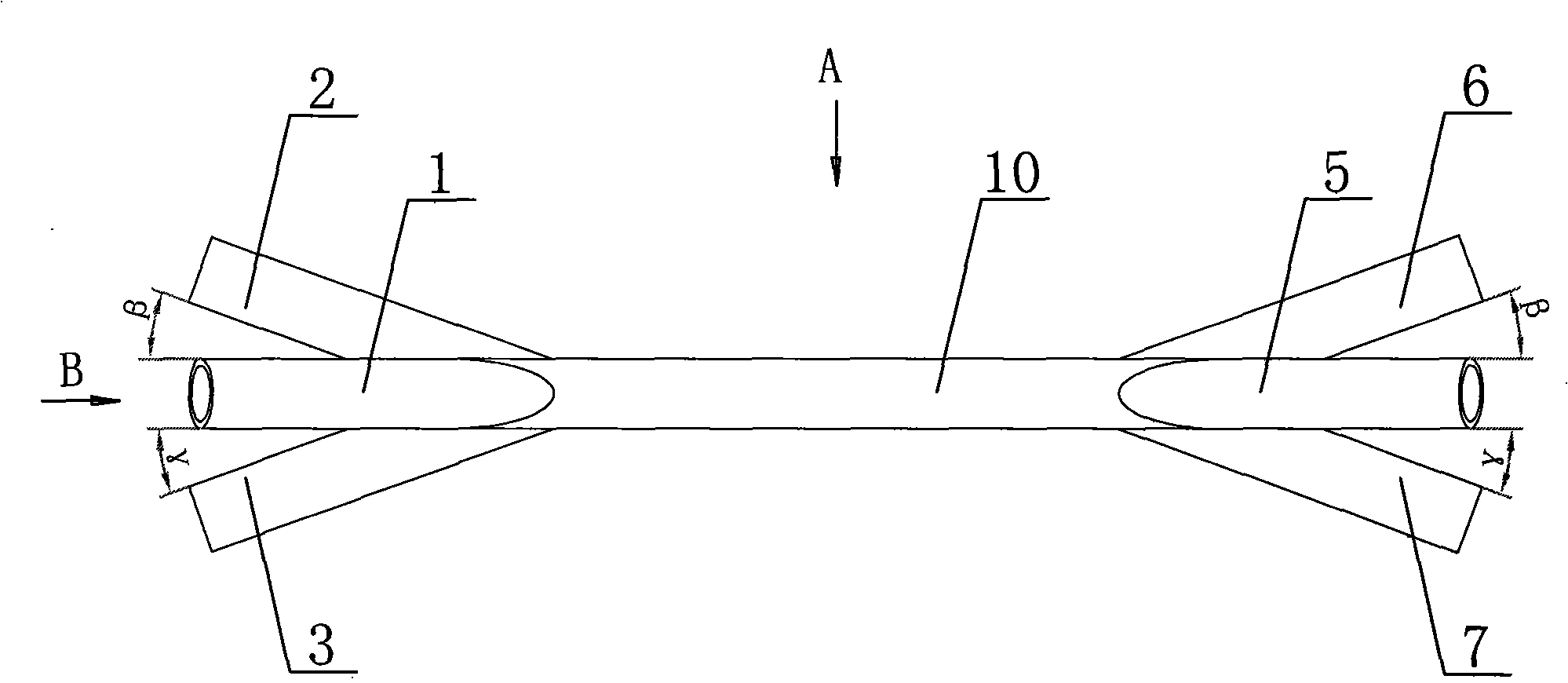

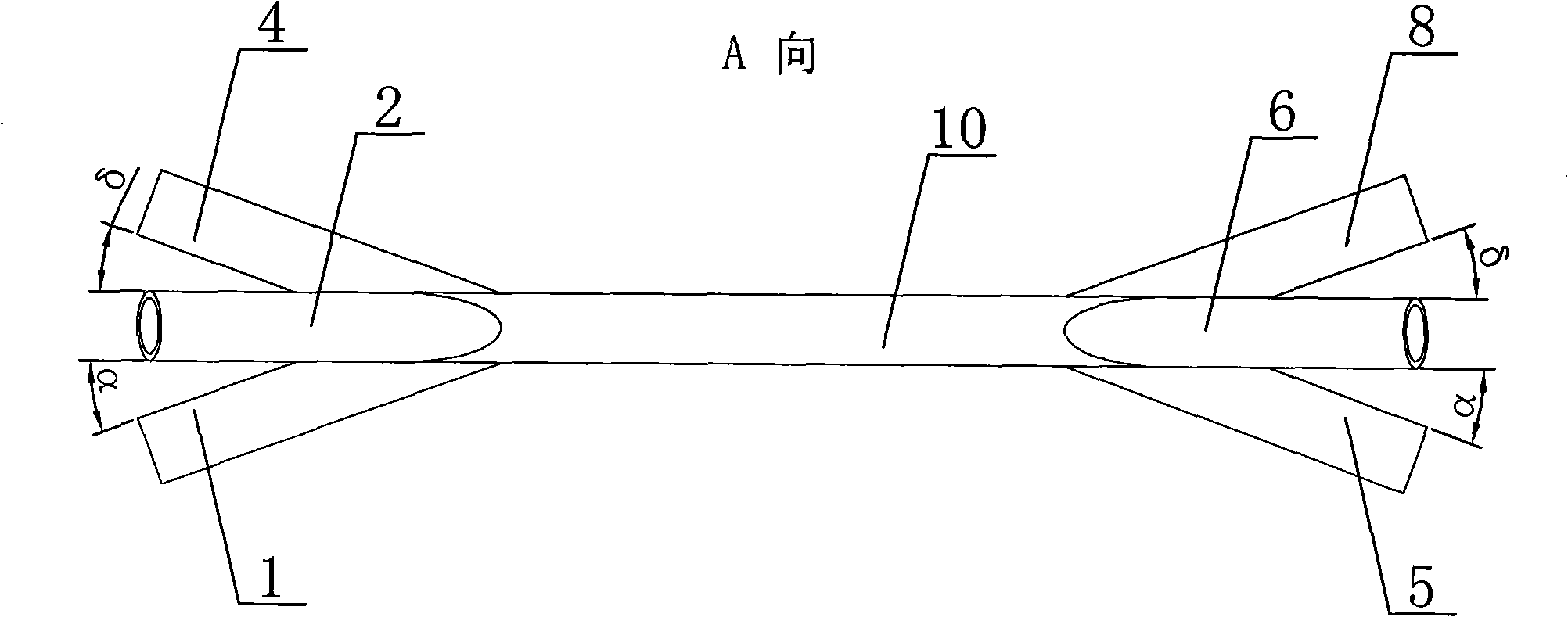

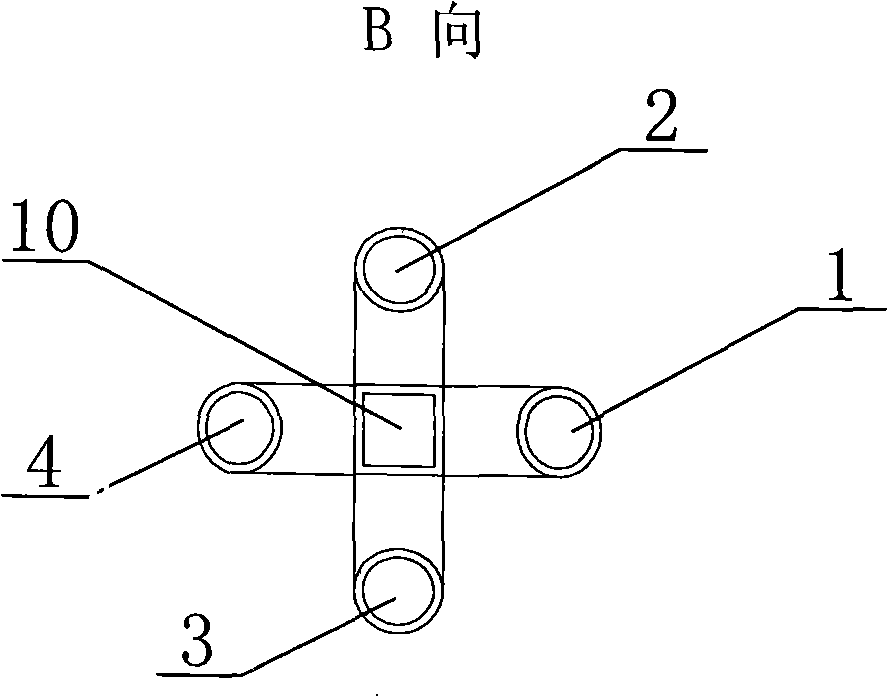

[0008] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment, this embodiment is made up of first assembly, second assembly and square element 10, described first assembly and second assembly are symmetrically arranged two ends of square element 10; Said first assembly is made up of first element 1 , the second element 2, the third element 3 and the fourth element 4, the first element 1, the second element 2, the third element 3 and the fourth element 4 are respectively arranged on the four side walls of one end of the square element 10 Above, the first component 1, the second component 2, the third component 3 and the fourth component 4 communicate with the square component 10; the second component consists of the fifth component 5, the sixth component 6, the seventh component 7 and The eighth element 8 is composed of the fifth element 5, the sixth element 6, the seventh element 7 and the eighth element 8 respectively arranged on the four sid...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Figure 4 Describe this embodiment, the angle α between the first element 1 and the fifth element 5 and the square element 10, the angle β between the second element 2 and the sixth element 6 and the square element 10, the angle β between the first element 1 and the fifth element 5 and the square element 10 in this embodiment. The angle γ between the third element 3 and the seventh element 7 and the square element 10 and the angle δ between the fourth element 4 and the eighth element 8 and the square element 10 are all 5-45°. With such a setting, it is easier to enter and exit the beam. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 4 Describe this embodiment, the angle α between the first element 1 and the fifth element 5 and the square element 10, the angle β between the second element 2 and the sixth element 6 and the square element 10, the angle β between the first element 1 and the fifth element 5 and the square element 10 in this embodiment. The angle γ between the third element 3 and the seventh element 7 and the square element 10 , and the angle δ between the fourth element 4 and the eighth element 8 and the square element 10 are all 5°. With such a setting, it is easier to enter and exit the beam. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com