Excimer broadband pumping alkali metal laser by adopting negative-branch confocal unstable-cavity structure

An alkali metal, unstable cavity technology, applied in the field of alkali metal lasers, can solve the problems of low conversion efficiency, achieve good uniformity, improve conversion efficiency, and achieve the effect of repeated pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

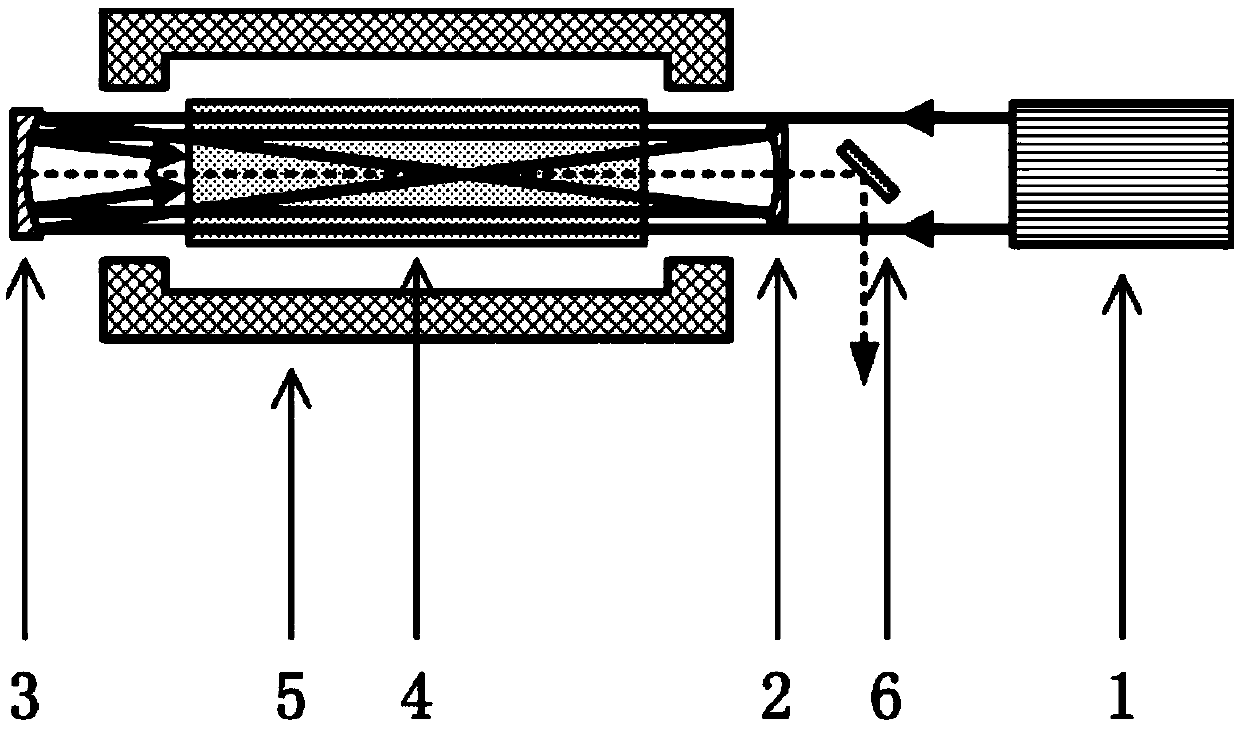

[0019] See attached for details figure 1 As shown, the main structure of the present invention includes: a pumping source 1, a concave reflector a 2, a concave reflector b 3, an alkali metal vapor pool 4, a heating furnace 5, and a flat high reflector 6.

Embodiment 2

[0023] See attached for details figure 1 As shown, the main structure of the present invention includes: a pumping source 1, a concave reflector a 2, a concave reflector b 3, an alkali metal vapor pool 4, a heating furnace 5, and a flat high reflector 6.

[0024] The specific implementation is:

[0025] The alkali metal vapor pool 4 is filled with sufficient cesium metal, and the alkali metal vapor pool 4 is also filled with krypton gas as a buffer gas. The inflation pressure of the krypton gas at room temperature is 1000 torr, and the alkali metal vapor pool 4 is heated by the heating furnace 5. When heated to 300°C, the pressure of cesium vapor at this temperature is 2.31torr; the outer surface of the windows at both ends of the alkali metal vapor pool 4 is coated with a 800-900nm waveband enhancement film; the pump source output laser wavelength is 841nm, which corresponds to cesium and The blue wing of the excimer formed by krypton (Cs-Kr) absorbs the center wavelength of the ...

Embodiment 3

[0027] See attached for details figure 1 As shown, the main structure of the present invention includes: a pumping source 1, a concave reflector a 2, a concave reflector b 3, an alkali metal vapor pool 4, a heating furnace 5, and a flat high reflector 6.

[0028] The specific implementation is:

[0029] The alkali metal steam pool 4 is filled with a sufficient amount of rubidium metal, and the alkali metal steam pool 4 is also filled with krypton gas as a buffer gas. The inflation pressure of the krypton gas at room temperature is 1400 torr, and the alkali metal steam pool 4 is heated by the heating furnace 5. When heated to 280°C, the pressure of rubidium vapor at this temperature is 0.78torr; the outer surface of the windows at both ends of the alkali metal vapor pool 4 is coated with a 730-830nm waveband enhancement film; the pump source output laser wavelength is 760nm, corresponding to rubidium and The blue wing of the excimer formed by krypton (Rb-Kr) absorbs the center wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com