Chipboard for containing flaky electronic unit

A technology of electronic components and cardboard, applied to paper, papermaking, paper coating, etc., can solve problems such as insufficient burr prevention effect and inability to solve burr obstacles, and achieve excellent bonding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

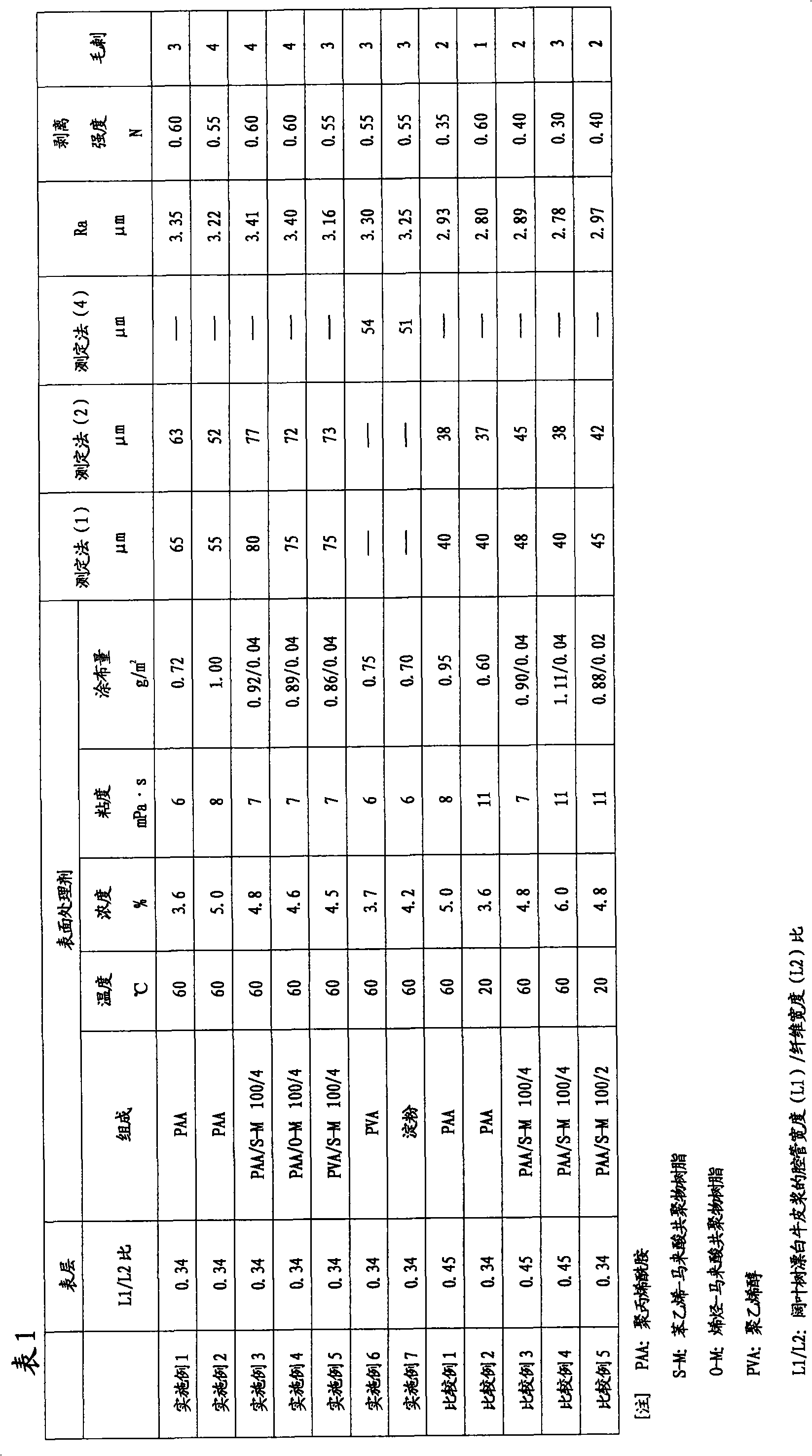

[0069] In Examples 1 and 2, different pulps were used to form the surface layer, middle layer, and back layer of the paper base material. That is, for the surface layer, LBKP 100% was beaten to prepare pulp with a Canadian standard freeness of 400 ml. At this time, the L1 / L2 ratio=0.34. In the middle layer, mix and beat according to the ratio of NBKP20% and LBKP80%, and prepare the pulp with Canadian international standard freeness of 350ml. Sulfuric acid tape was added to each pulp slurry to adjust pH to 6.0, and 0.3% of polyacrylamide (Polysteron-1250 manufactured by Arakawa Chemical Co., Ltd.) was added as an internal paper strength enhancer. The above-mentioned various pulp slurries are supplied to the short-wire paper machine, and the quantitative adjustment is made into a surface layer: 100g / m 2 , middle layer: 200g / m 2 , inner layer: 50g / m 2 , papermaking is carried out by papermaking method, and the obtained 3-layer base paper is smoothed by a calender installed in...

Embodiment 3

[0079] Same as Examples 1-2, the production weight is 350g / m 2 , Thickness 0.42mm sheet-type electronic components storage cardboard. However, in the surface treatment agent coating liquid, polyacrylamide (Arakawa Chemical Co., Polymaset-512 (trademark), molecular weight: 200,000) and styrene-maleic acid copolymer resin (Arakawa Chemical Co., Ltd. Polymaron-382 (trademark)), the surface treatment agent coating solution was adjusted at a temperature of 60°C, a surface treatment agent concentration of 4.8%, and a viscosity of 7 mPa·s, and coated on the base paper. At this time, the coating amount is polyacrylamide solid content: 0.92g / m 2 , Styrene-maleic acid copolymer resin solid content: 0.04g / m 2 . The penetration depth of the surface treatment agent at this time (measurement method (2) of penetration depth) was 77 μm. 2% fluorescent dye (Kayahor PBS Liquid (trademark) manufactured by Nippon Kayaku Co., Ltd.) was mixed with the same surface treatment agent coating soluti...

Embodiment 4

[0081] Cardboard for storing sheet-shaped electronic components was produced in the same manner as in Example 3. However, an olefin-maleic acid copolymer resin (manufactured by Arakawa Chemical Co., Ltd., Polymaron-482 (trademark)) was used instead of a styrene-maleic acid copolymer resin as a surface treatment agent coating liquid component, and the surface treatment agent was applied Liquid: 60° C., surface treatment agent concentration: 46%, viscosity: 7 mPa·s coating liquid. At this time, the coating amount is 0.89g / m for polyacrylamide 2 , for olefin-maleic acid resin is 0.04g / m 2 . The penetration depth of the surface treatment agent at this time (measurement method (2) of penetration depth) was 72 μm. 2% fluorescent dye (manufactured by Nippon Kayaku Co., Ltd., Kayahor PBS Liquid (trademark)) was mixed with the same surface treatment agent coating liquid as above, and the penetration depth was measured by fluorescence color development. The measured value of the pene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Centerline average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com