Sheet feeding mechanism and adaptable automatic paper feeder

A technology of automatic paper feeding device and paper feeding mechanism, which is applied in the directions of transportation and packaging, separation of objects, separation of piles, etc., can solve the problems of increasing production cost, increasing system burden, and high motor loss rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the present invention can have various changes in different ways, all of which do not depart from the scope of the present invention, and the description and illustrations therein are used as illustrations in nature, not to limit the present invention .

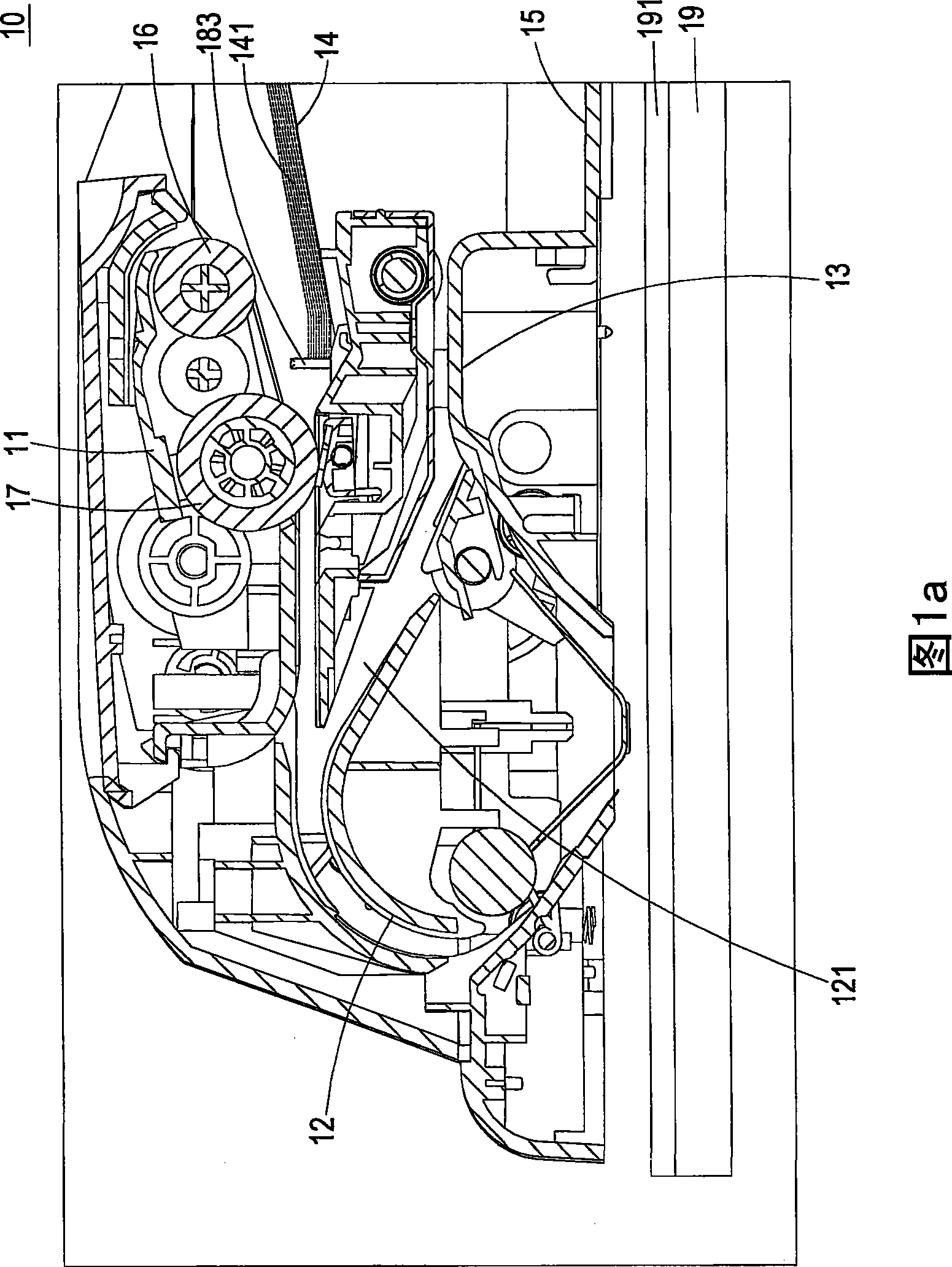

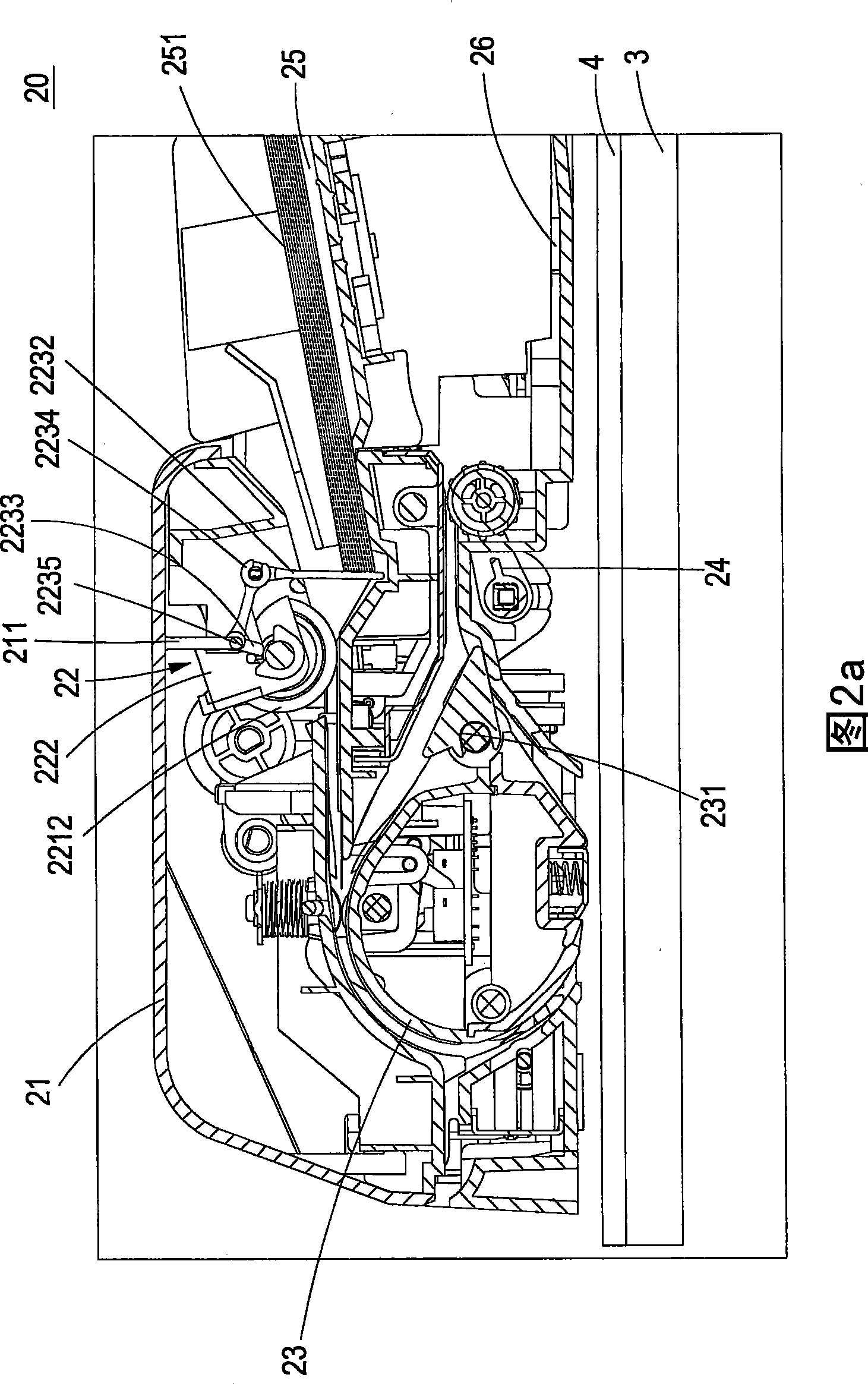

[0048] Please refer to Figure 2a, which is a schematic structural view of the automatic paper feeding device of a preferred embodiment of the present invention when it is not feeding paper. A business machine, such as a scanner, at least includes an outer casing 21, a paper feeding mechanism 22, a conveying mechanism 23, a discharge mechanism 24, a paper feeding tray 25, and a paper discharging tray 26, wherein the paper feeding tray 25 can stack a plurality of paper sheets 251 , and the paper feeding mechanism 22 is used to sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com