Perovskite type oxide, preparation method thereof and application of perovskite type oxide in preparation of carbon monoxide

A perovskite type and carbon monoxide technology, applied in the direction of carbon monoxide, can solve the problems of complex gas products, slow reaction rate, large demand, etc., and achieve the effect of increasing oxygen capacity, high selectivity, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

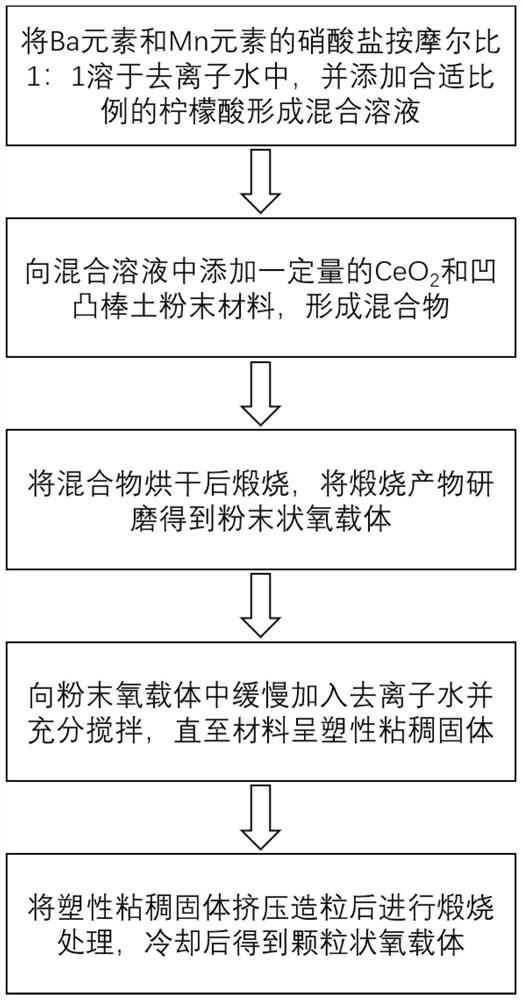

[0034] The preparation method of a perovskite oxide provided in the embodiment of the present invention, such as figure 1 shown, including the following steps:

[0035] S1. Prepare its nitrate solution according to the molar ratio of Ba and Mn metal ions of 1:1, and then add citric acid to the nitrate solution to obtain BaMnO 3 A mixed solution of components.

[0036] S2. Add CeO to the mixed solution 2 powder carrier material, and stir evenly; then add attapulgite powder carrier material to the mixed solution, and disperse evenly to obtain a mixture;

[0037] S3, the mixture is calcined and then granulated, which specifically includes the following steps:

[0038] S31, drying the mixture, then calcining the mixture, and grinding the calcined product to obtain a powdered oxygen carrier material;

[0039] S32. Slowly add deionized water to the powdered oxygen carrier material, and at the same time fully stir with a glass rod, until the material is a plastic viscous solid, a...

specific Embodiment

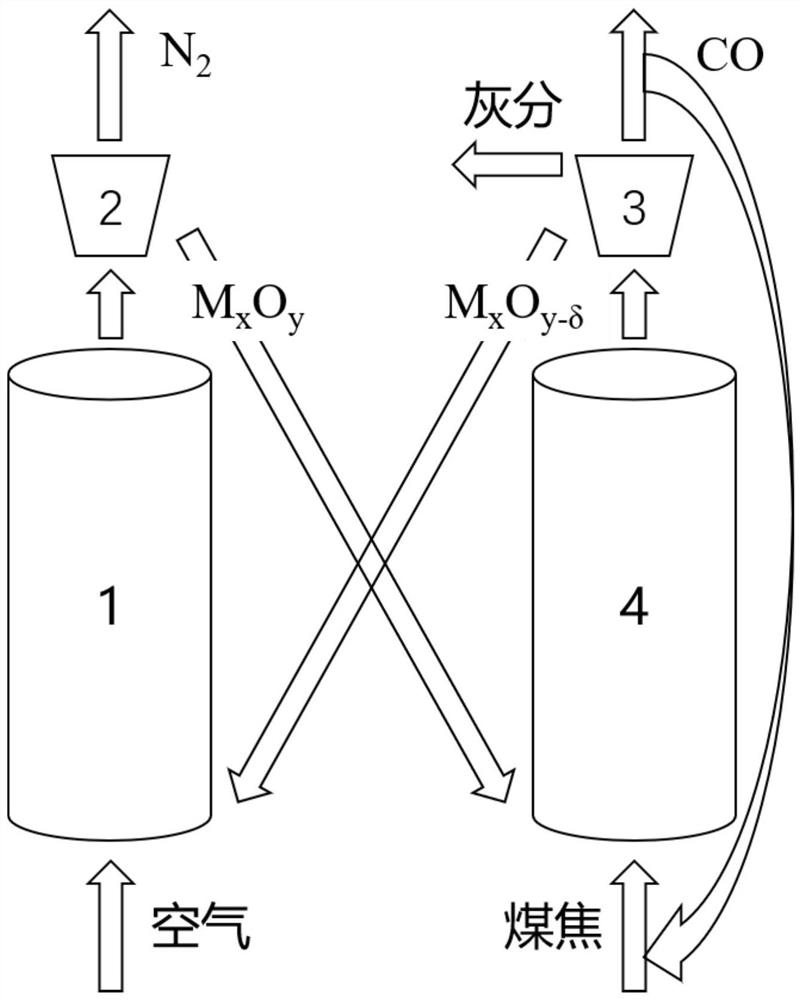

[0056] To test and prove BaMnO 3 , CeO 2 , the content of attapulgite on the performance of oxygen carrier, a total of two groups of experiments are given. In both sets of experiments, the prepared oxygen carrier was used to prepare carbon monoxide, and when carbon monoxide was prepared, the reaction temperature in the fuel reactor was 900 °C, and the mass ratio of coal char to oxygen carrier was 1:25.

[0057] The first set of experiments: testing BaMnO 3 with CeO 2 The influence of molar ratio is shown in Table 1; the content of attapulgite added is 40%, and other preparation parameters are the same.

[0058] Table 1 BaMnO 3 with CeO 2 The effect of molar ratio

[0059] group BaMnO 3 : CeO 2

Carbon conversion rate (%) CO concentration (%) Example 1 1:0.5 75 85 Example 2 1:1 92 89 Example 3 1:2 88 91 Comparative Example 1 CeO2 free 63 80 Comparative Example 2 Direct use of LaFeO 3

12 42 Comparative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com