A kind of preparation method of uranium niobium molybdenum alloy

A niobium alloy, niobium-molybdenum technology, applied in the field of metal smelting and forming process and alloy preparation, can solve the problems of material loss and impurity increase, long cycle, complicated process, etc., to achieve increased superheat, high purity, dissolution and diffusion full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The raw materials of uranium, niobium and molybdenum are prepared, the uranium metal is an ingot with a carbon content of ≤100μg / g, the niobium raw material is a wire with a purity greater than 99.9%, and the molybdenum raw material is a wire with a purity greater than 99.9%.

[0051] The operation steps of preparing U-5Nb-3Mo alloy are as follows:

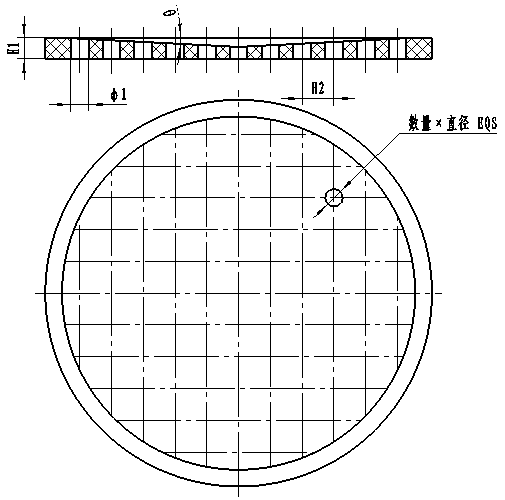

[0052] (1) When batching, the weight ratio of niobium is 5.2wt.%. The uranium metal and niobium raw materials are cleaned and put into the electron beam melting furnace, and the combined furnace is vacuumed to 2*10 -2 Power transmission after Pa, preheating at 800°C for 6 minutes, then gradually raising the temperature to 2800°C to completely melt the uranium and niobium raw materials, then cooling down to 2550°C for 30 minutes, adjusting the scanning frequency of the electron beam to 10Hz, using circular wave scanning, Make the electron beam spot spirally move from the center of the water-cooled copper crucible to the edge...

Embodiment 2

[0056] The raw materials of uranium, niobium and molybdenum are prepared, the uranium metal is an ingot with a carbon content of ≤100μg / g, the niobium raw material is a rod with a purity greater than 99.9%, and the molybdenum raw material is a wire with a purity greater than 99.9%.

[0057] The operation steps of preparing U-4Nb-4Mo alloy are as follows:

[0058] (1) When batching, the weight ratio of niobium is 3.9wt.%. The uranium metal and niobium raw materials are cleaned and put into the electron beam melting furnace, and the combined furnace is vacuumed to 2*10 -2 Power transmission after Pa, preheat at 600°C for 6 minutes, then gradually increase the temperature to 3000°C to completely melt the uranium and niobium raw materials, then cool down to 2500°C for 25 minutes, adjust the scanning frequency of the electron beam to 10Hz, and use circular wave scanning. Make the electron beam spot spirally move from the center of the water-cooled copper crucible to the edge of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com