Hidden installation hand hole molding mould

A forming mold and concealed technology, applied in the directions of molds, ceramic forming cores, ceramic forming mandrels, etc., can solve problems such as the inability to meet concealed hand holes, and achieve the effect of increasing the number of turnover utilization, convenient dismantling, and ensuring forming requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

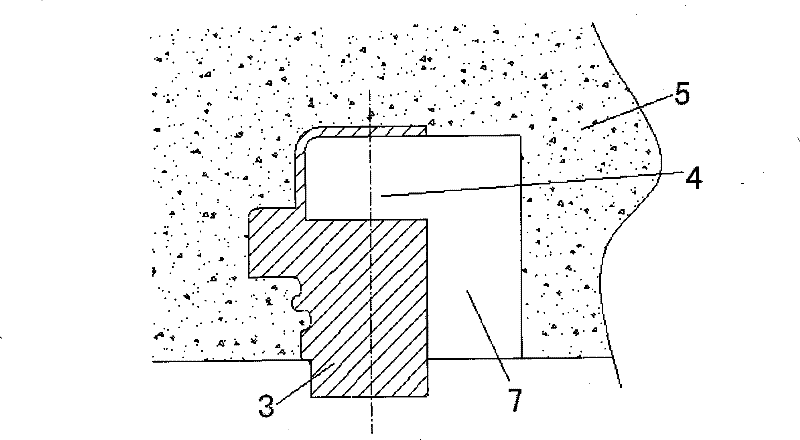

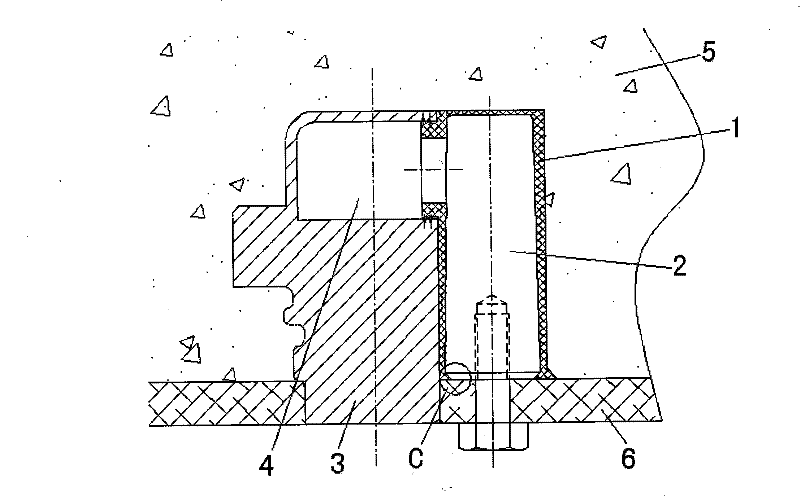

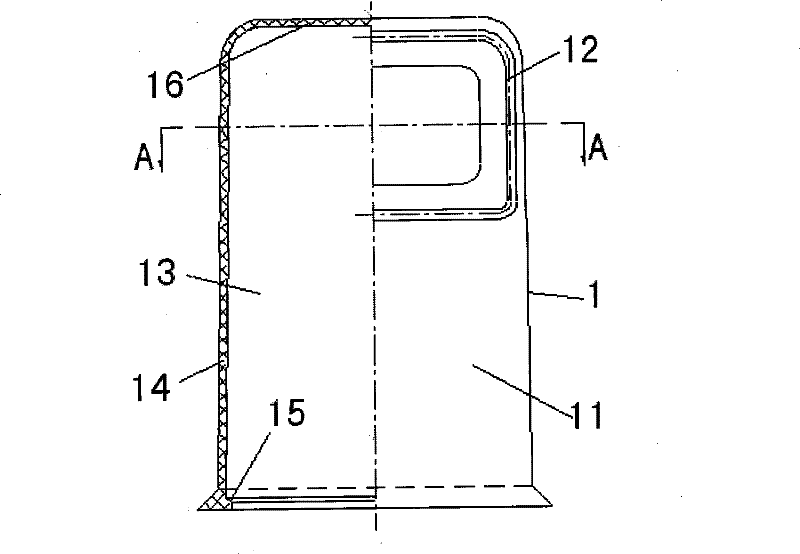

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] Such as Figure 1~5 As shown, the concealed installation hand hole forming mold of the present invention includes a shaped rubber sleeve 1 and an iron vertical mandrel 2. The shaped rubber sleeve 1 includes a vertical rubber sleeve main body 11 and a sealing spigot 12. The rubber The top of the sleeve body 11 is closed, and the sealing seam 12 protrudes laterally from the side wall of the rubber sleeve body corresponding to the cavity 4 of the embedded part. The entire shaped rubber sleeve is in a small "L" shape. The sealing seam 12 The shape is adapted to the shape of the cross-section of the embedded part cavity 4, and the sealing spigot 12 extends into the embedded part cavity to seal the port of the embedded part cavity; the iron vertical mandrel 2 is arranged on a rubber In the inner cavity 13 of the main body of the cover, it is adaptively matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com