Industry method of oil backfilling by manufacturing alkaline residue after the entire cleaning of the alkaline residue pool

A technology of backfilling soil and alkali slag, which is applied in filling, solid waste removal, sustainable waste treatment, etc., can solve the problems of ecological environment damage, large land occupation, etc., achieve less intermediate links, save land resources, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

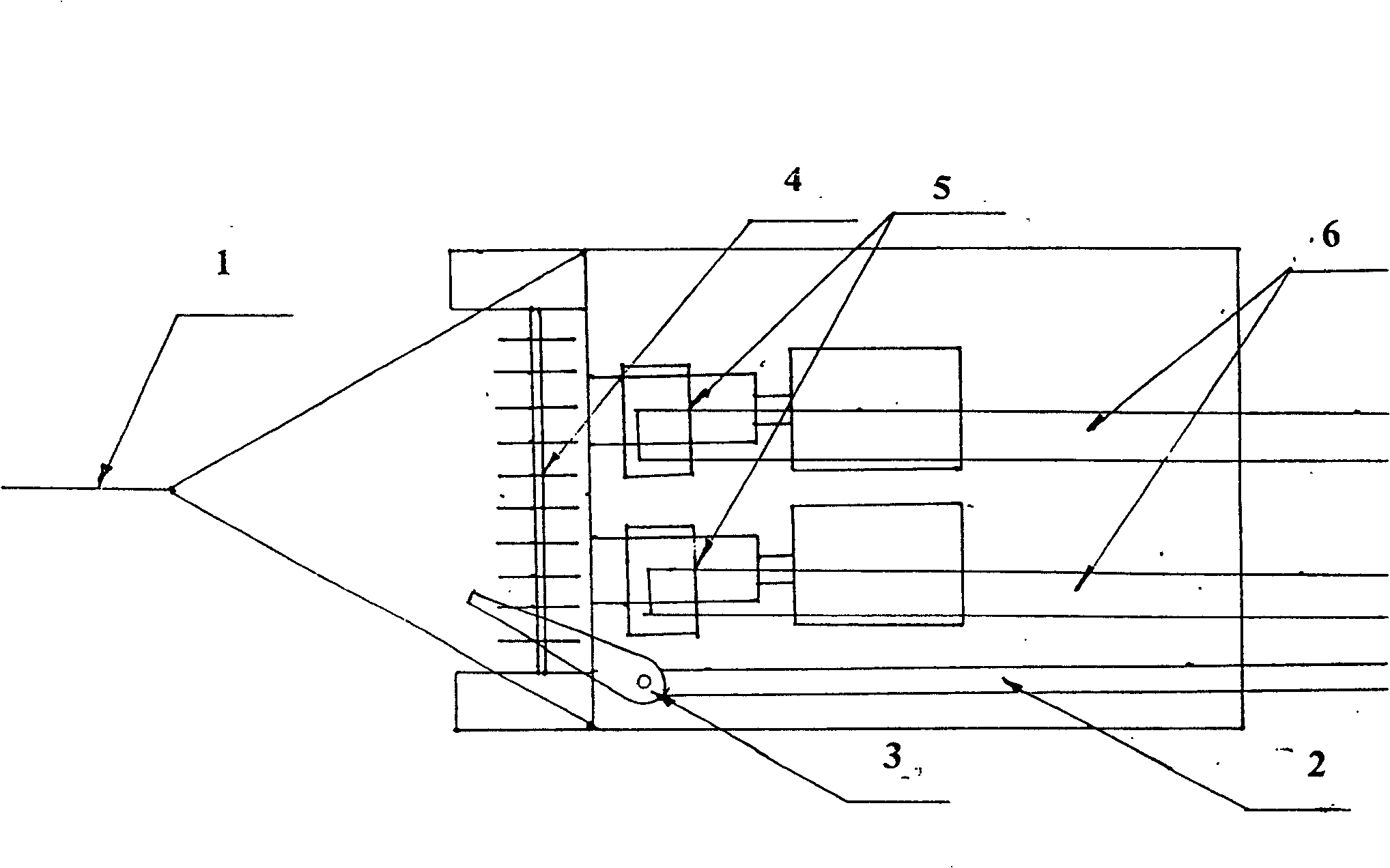

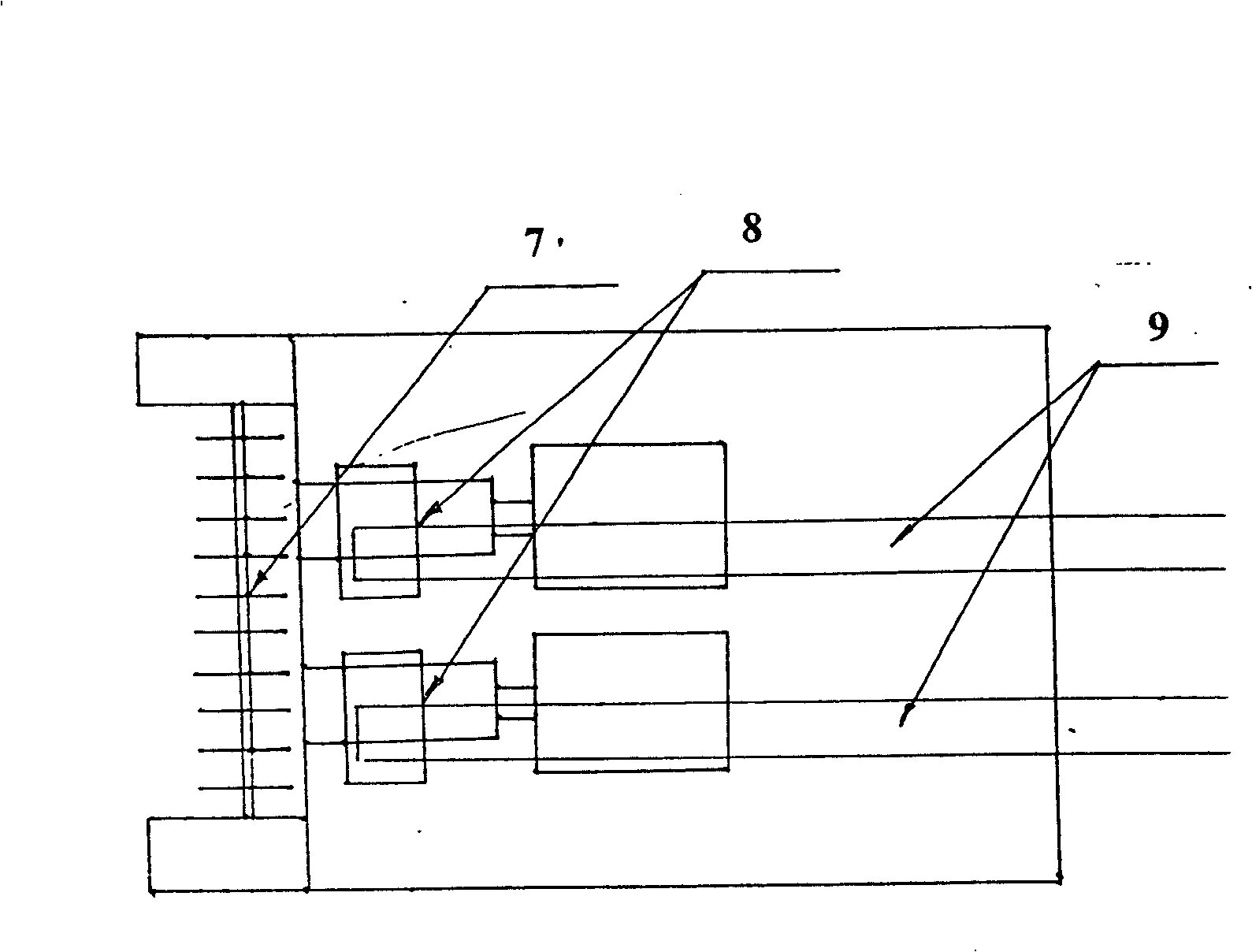

Image

Examples

Embodiment

[0076] The method for cleaning the soda plant alkali slag pool and making it into urban industrial backfill soil comprises the following steps:

[0077] 1. Treatment of backfilling sites:

[0078] a. Build a dam on all sides of the backfill site. The dam surface is 2 meters wide, the bottom is 4 meters, and the area is 100 meters x 100 meters.

[0079] b. When building the dam, dig the ditch with soil. The depth of the ditch is 50 cm to 70 cm.

[0080] c. Install water pumps deep in the ditch in the backfill area to drain water every day to speed up the drying of the dam.

[0081] d. Let the soil in the backfill area dry in the sun until the excavator can start freely and carry out construction work before discharging alkali slag.

[0082] 2. Alkali slag treatment in the alkali slag pool:

[0083] a. Use an excavator to dig out the dam of the alkali slag pool, and excavate a channel at the bottom of the alkali slag pool for trucks and mixing conveyors to enter and exit.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap