Substrate processing sytstem and apparatus

A substrate processing device, substrate processing system technology, applied in the direction of optics, instruments, discharge tubes, etc., can solve the problems of uneven distribution of plasma, side wall peeling, generation of particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

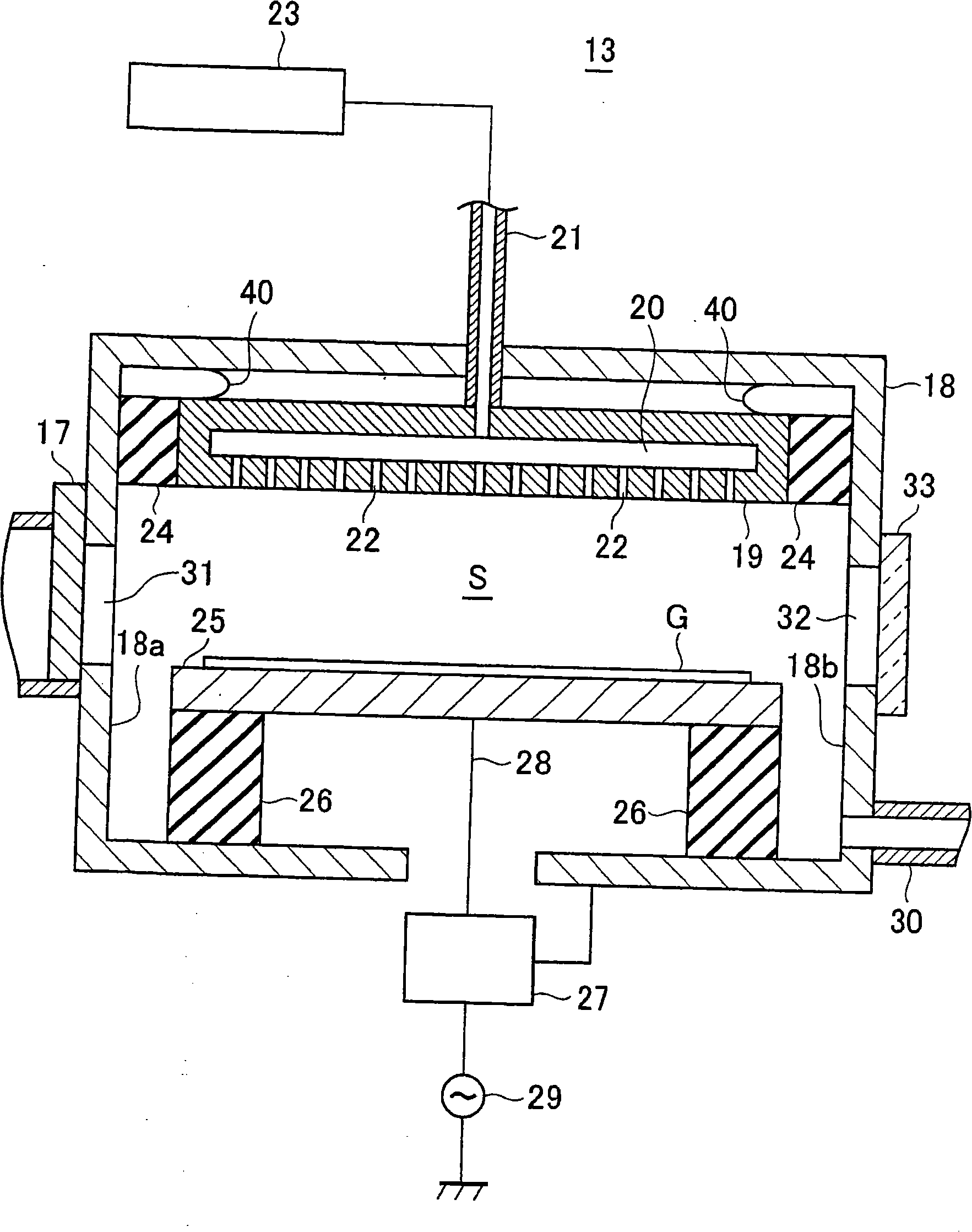

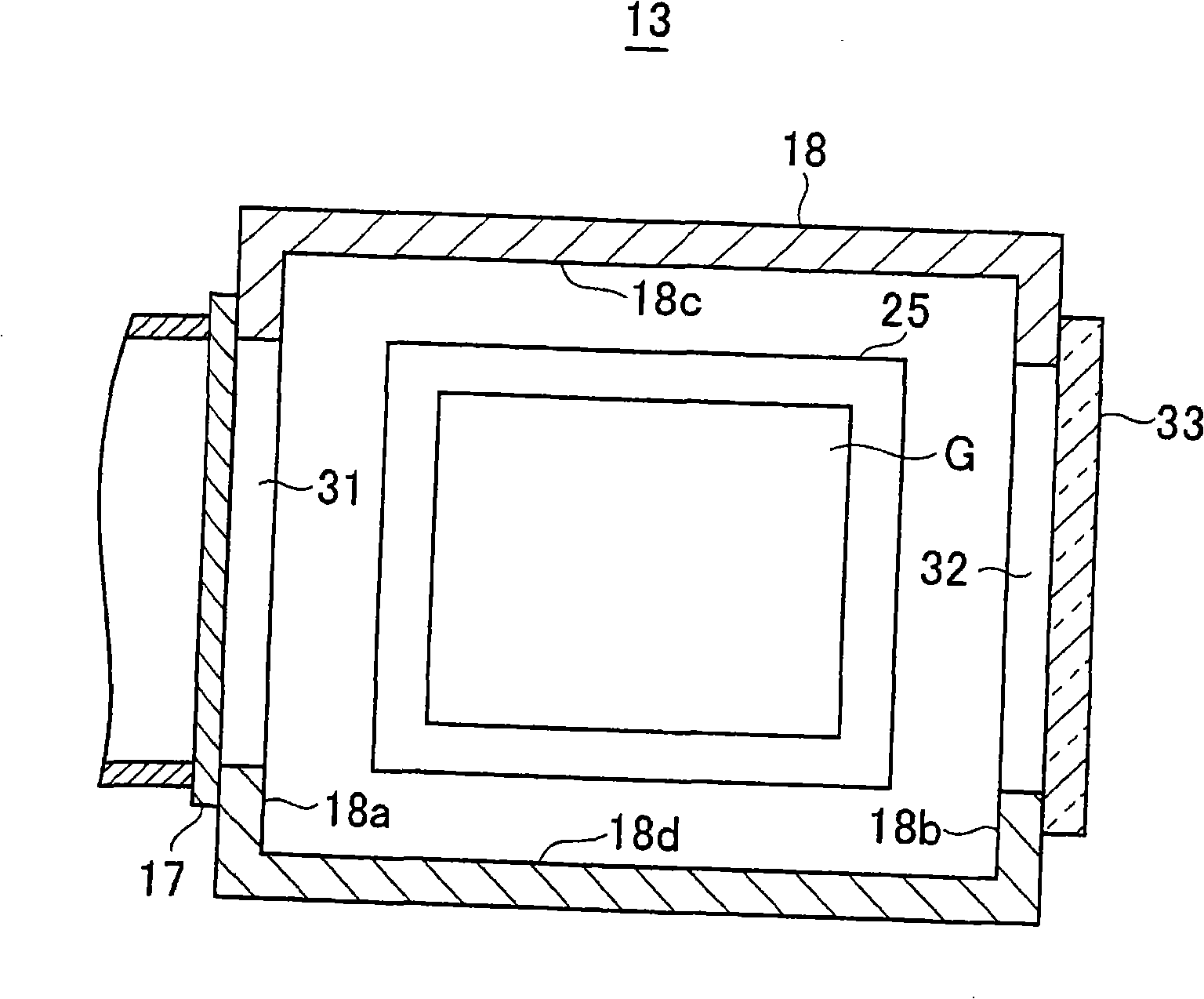

[0033] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0034] First, a substrate processing system according to an embodiment of the present invention will be described.

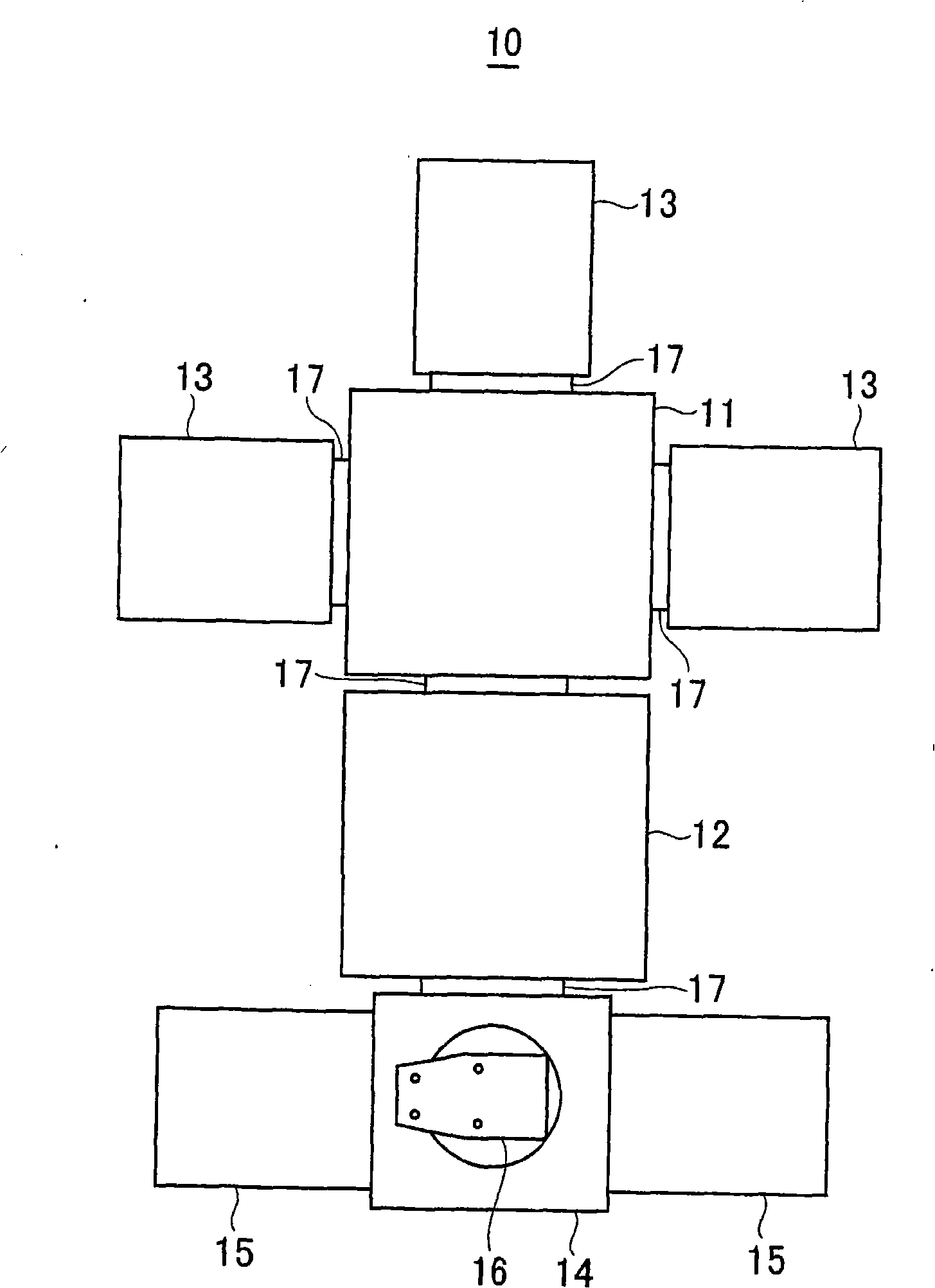

[0035] figure 1 It is a plan view schematically showing the configuration of the substrate processing system according to the embodiment of the present invention. This substrate processing system is a multi-chamber type substrate processing system for etching a glass substrate for FPD.

[0036] exist figure 1 Among them, the substrate processing system 10 includes: a transfer chamber 11 arranged in the center; a load lock chamber 12 connected to the transfer chamber 11; device); on the opposite side with the transfer chamber 11, the arm support platform 14 connected to the load lock chamber 12;

[0037] One box 15 is used to store a plurality of unprocessed glass substrates (hereinafter simply referred to as “substrates”) G, and the other box 15 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com