Loudspeaker and its manufacturing method

A manufacturing method and loudspeaker technology, which is applied in the field of loudspeakers, can solve problems such as full-frequency distortion, limited remedial measures, and scrapped products, and achieve the effects of improving product performance, increasing product manufacturing pass rate, and improving pronunciation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the implementation methods and accompanying drawings.

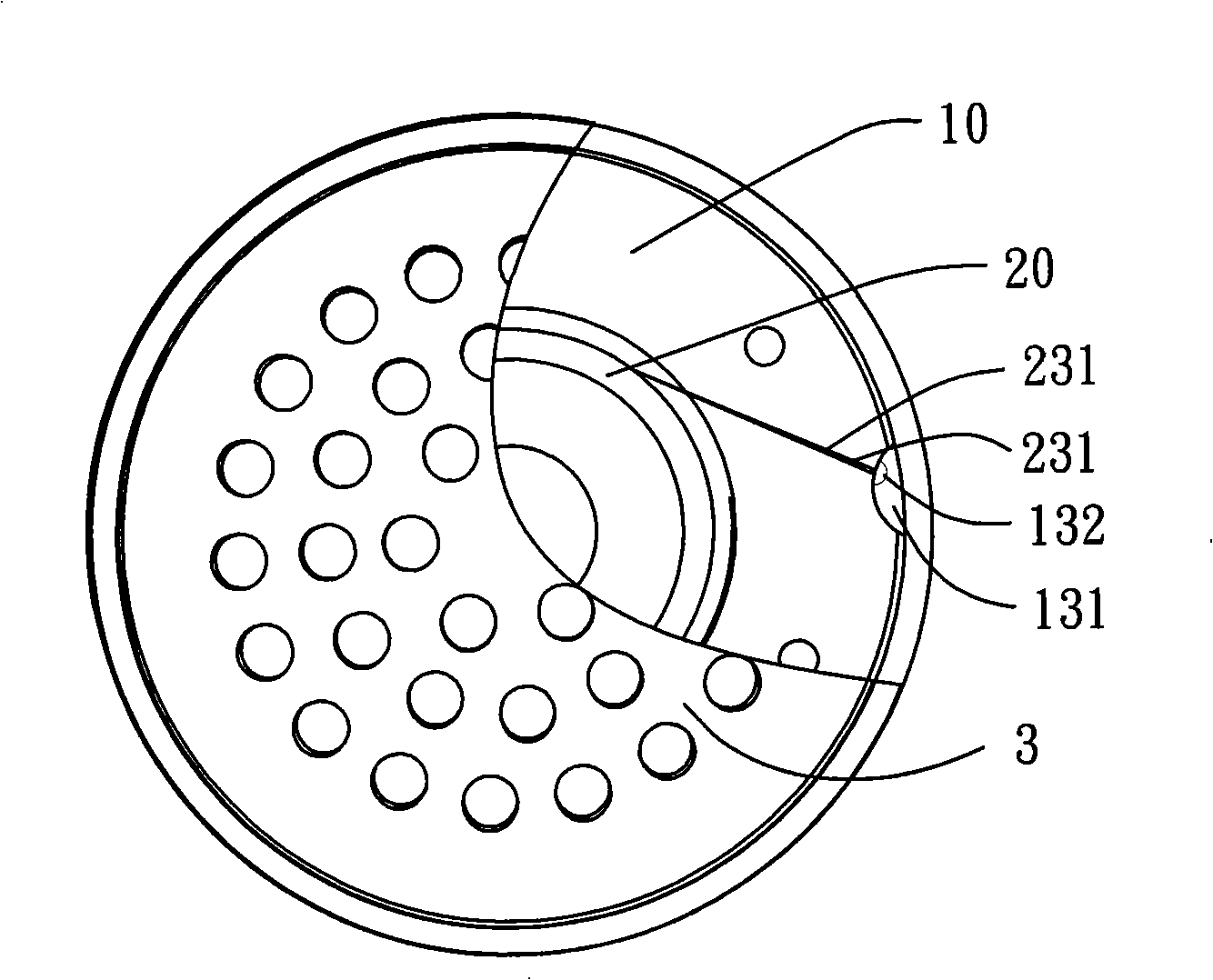

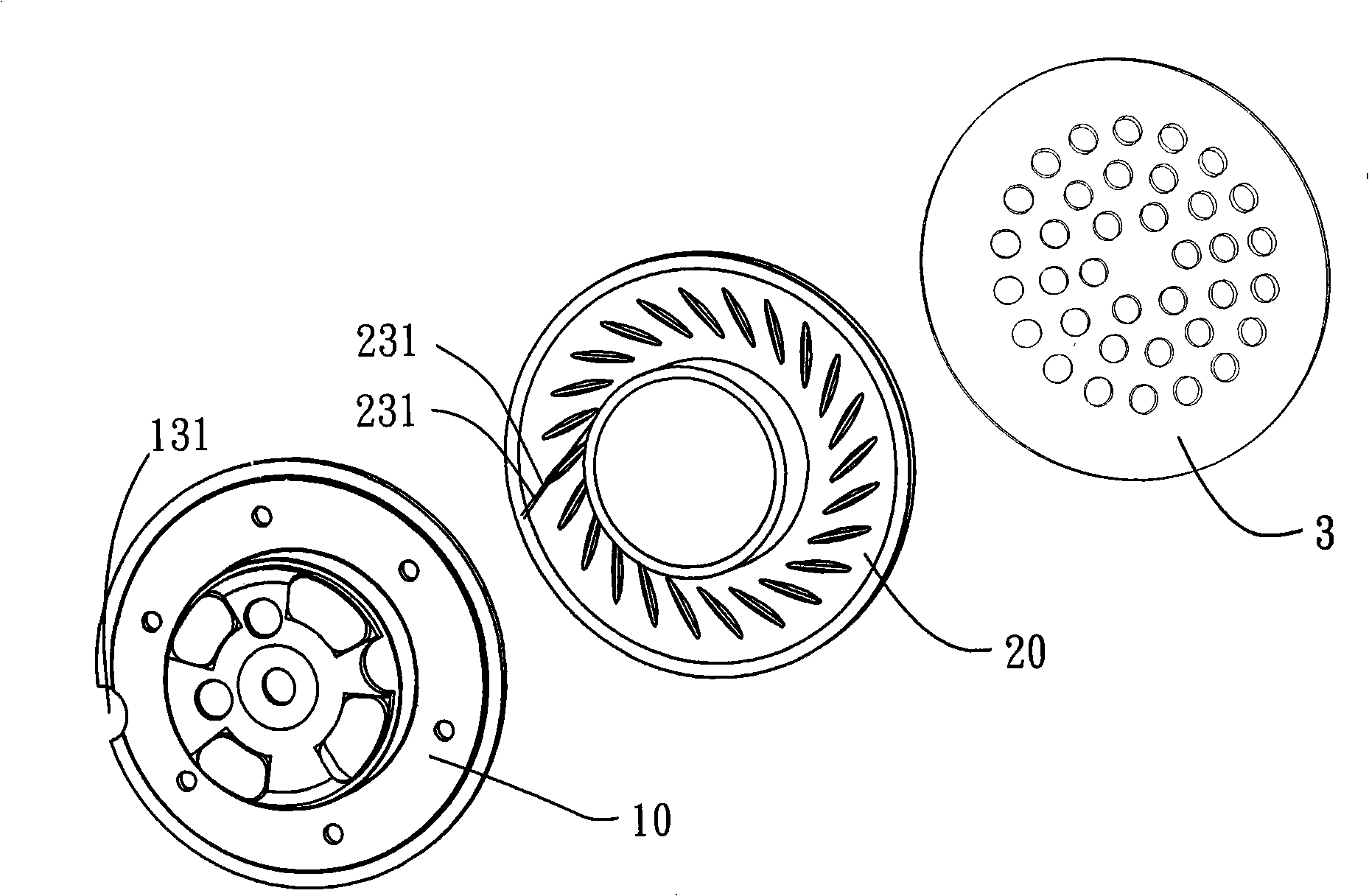

[0033] see figure 1 and figure 2 , the loudspeaker of the present invention includes a basin assembly 10 . A sounding assembly 20 is fixed on the front of the basin frame assembly 10 . The front of the pronunciation assembly 20 is fixed with a magnetically conductive mesh cover 3 .

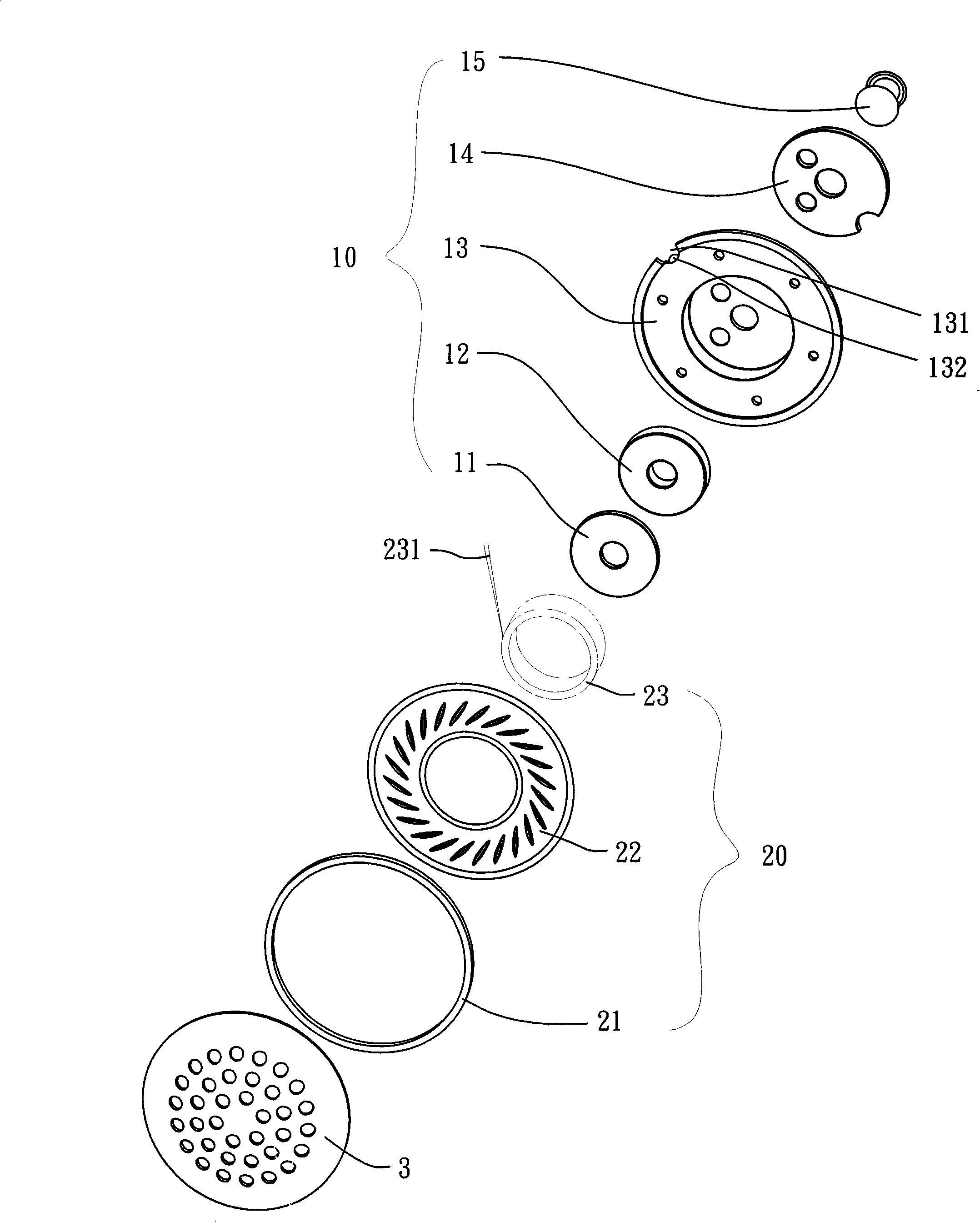

[0034] see image 3 , the pot frame assembly 10 includes a pot frame 13, and the pot frame 13 has a pot frame gap 131 thereon. The back of the pot frame 13 is provided with a PCB board 14 , and the cavity at the front of the pot frame 13 is provided with a magnet block 12 and a magnetically conductive sheet 11 . The magnetic conductive sheet 11 , the magnet block 12 , the basin frame 13 and the PCB board 14 are fixed together by rivets 15 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com