Dry desulfurizing process implementing automatic control based on environment friendly monitoring network and numeration table

A technology of dry desulfurization and monitoring network, which is applied in the direction of measuring devices, separation methods, chemical instruments and methods, etc., can solve the problems of not being able to automatically control the desulfurization system and monitor the amount of desulfurization agent in real time, and achieve the effect of improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

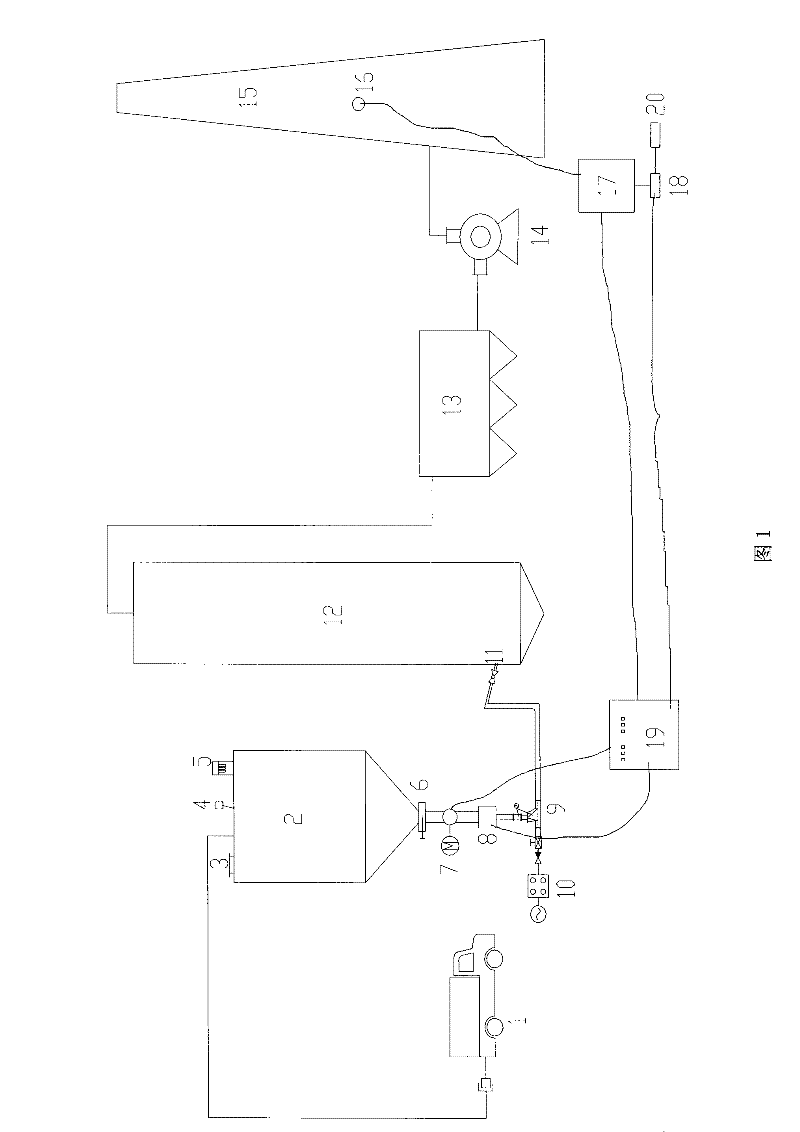

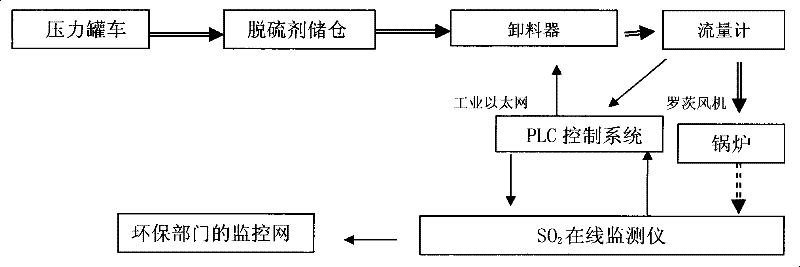

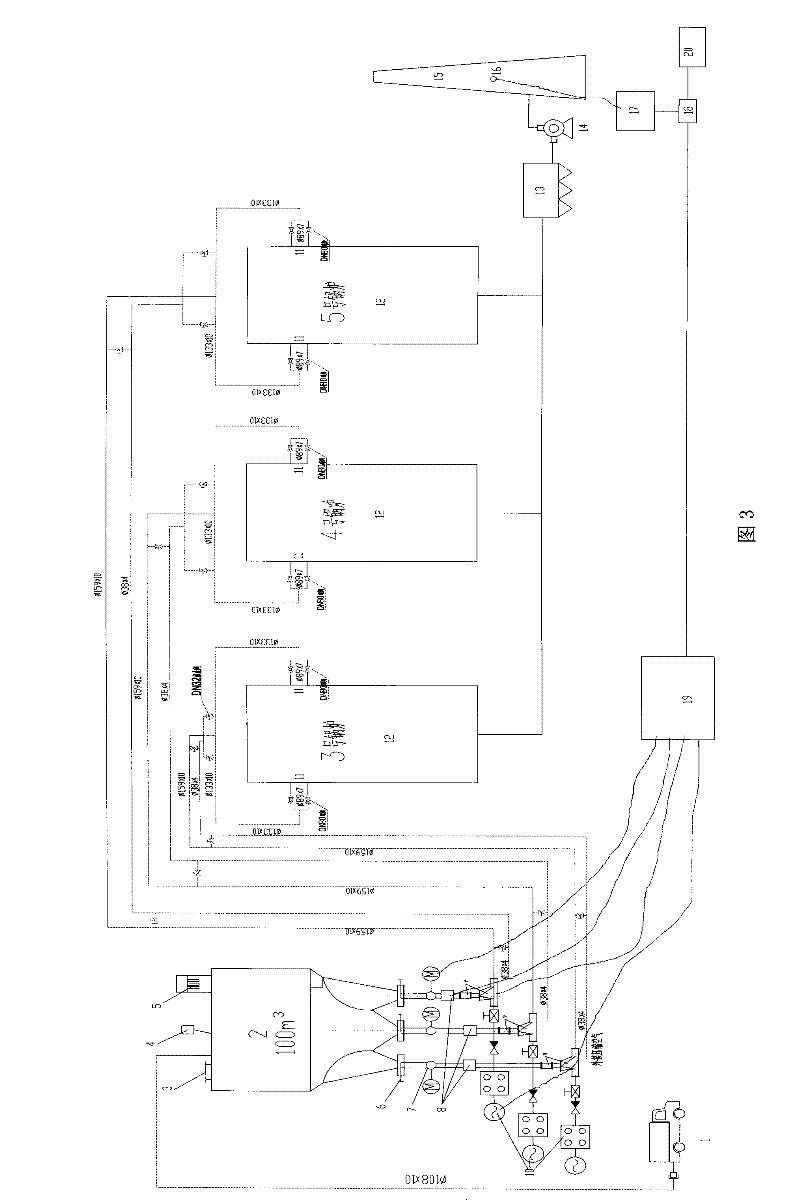

[0037] The tonnage of a circulating fluidized bed boiler in a power plant is designed to be 2×75t / h+1×90t / h, and the desulfurization method of the present invention is adopted, and the process flow is as follows image 3 shown.

[0038] The specific design basis is as follows:

[0039] Sulfur content in coal ≤ 1.7%

[0040] During normal production, the coal consumption of a single boiler is ≤14.5t / h

[0041] Boiler flue gas volume 150000m 3 / h

[0042] SO before desulfurization 2 Emission concentration 2660mg / Nm 3

[0043] Implement the method that the present invention applies PLC control system to implement the calcium spray desulfurization in circulating fluidized bed boiler furnace:

[0044] Purchased desulfurizer --- limestone powder pressure tanker 1, pneumatically conveyed (0.2MPa) to 100m by the on-board pump 3 In the storage bin 2, the particle size of the desulfurizer is required to be 0.01-1mm. The top of the storage bin is equipped with a pressure release va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com