Double-combination dual-shaft synchronous oscillation device

A synchronous vibration, dual-combination technology, applied in vibration conveyors, fluids utilizing vibration, furnace components, etc., can solve the problems of long smelting cycle, application, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

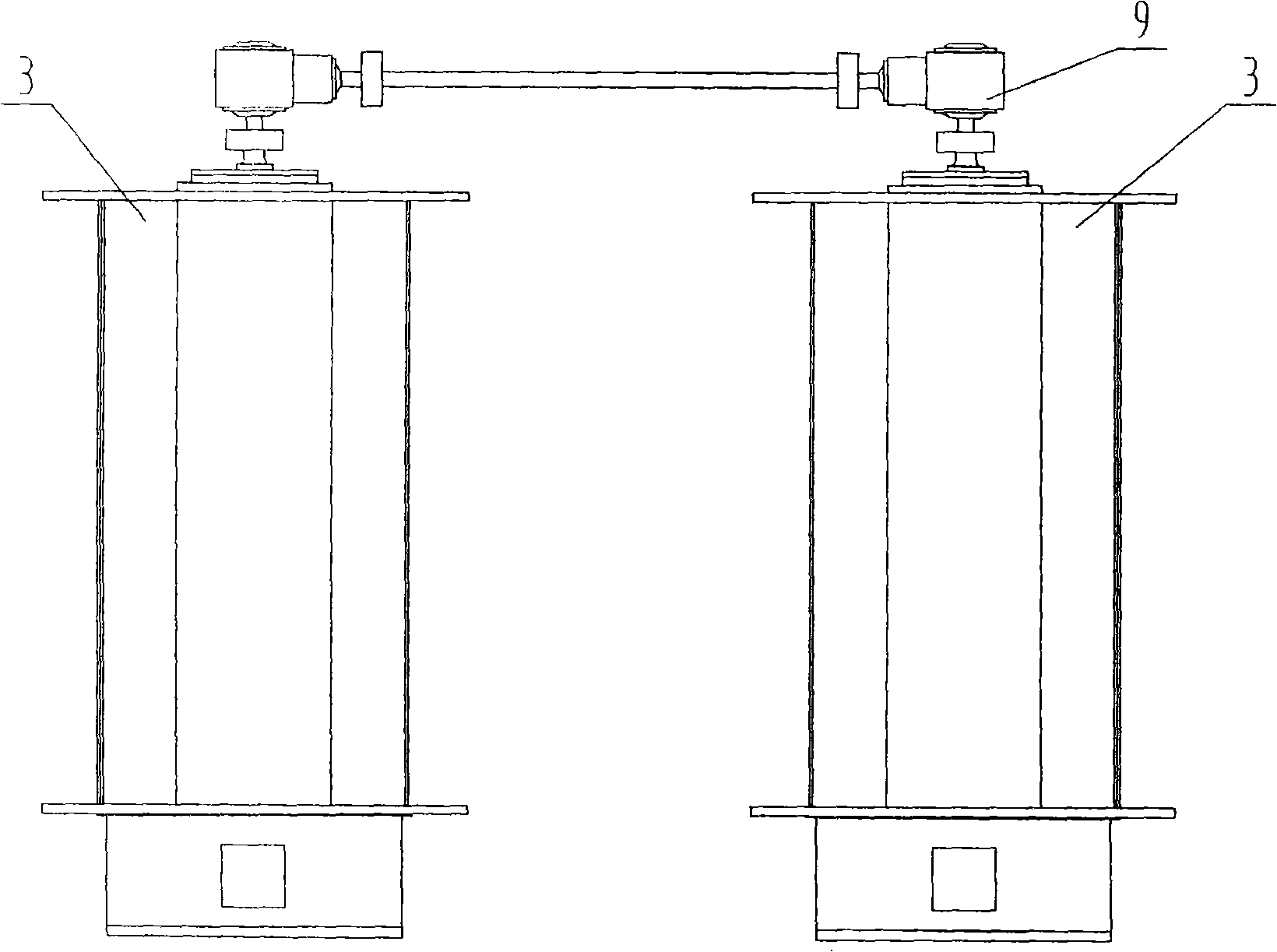

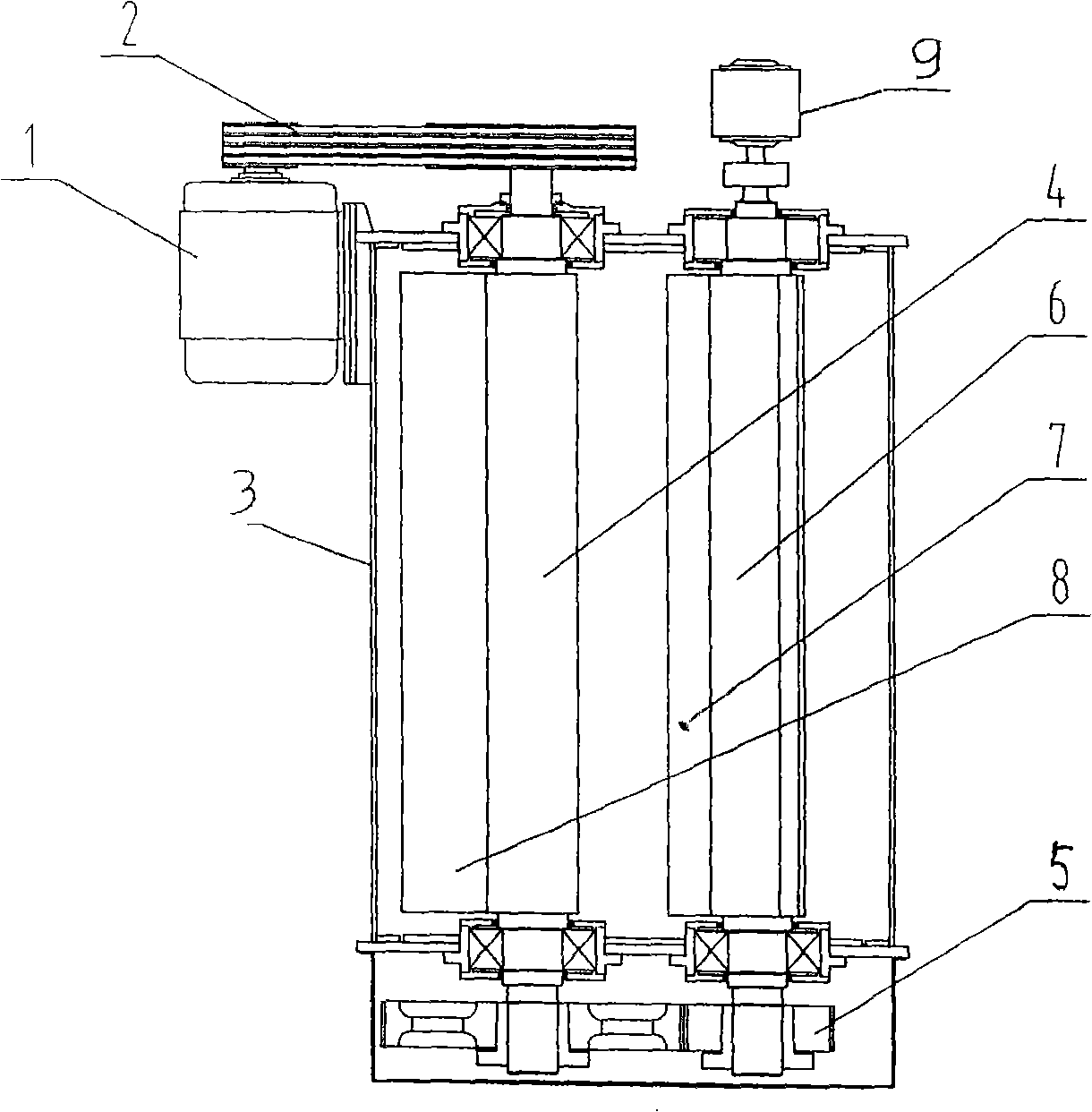

[0007] The embodiment is described in detail in conjunction with the accompanying drawings. The present invention is an improvement to the existing two-axis synchronous vibrator. A direction-changing transmission shaft mechanism 9 is connected between two ends of the two two-axis synchronous vibrator 3 passive eccentric shafts 6, and at the same time The end of each active eccentric shaft is respectively connected with a motor 1 through a pulley 2, and the other end of each active eccentric shaft is driven by a gear 5 to drive a passive eccentric shaft 6, and two eccentric shafts with different speeds are installed with different widths. The eccentric blocks 7 and 8 are provided with adjustable angles between the eccentric blocks of different widths. This kind of non-resonant linear vibrating conveyor, when working, the motor drives the two two-axis vibrators to work synchronously through the belt. The four eccentric shafts rotate at the same time to offset the force in the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com