Target plate for positioning components

A technology for positioning components and target plates, which is applied in the field of optical systems, can solve problems such as complicated use, easy damage, and obstacles to smooth operation, and achieve the effects of ensuring stability, eliminating backscattering, and eliminating irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

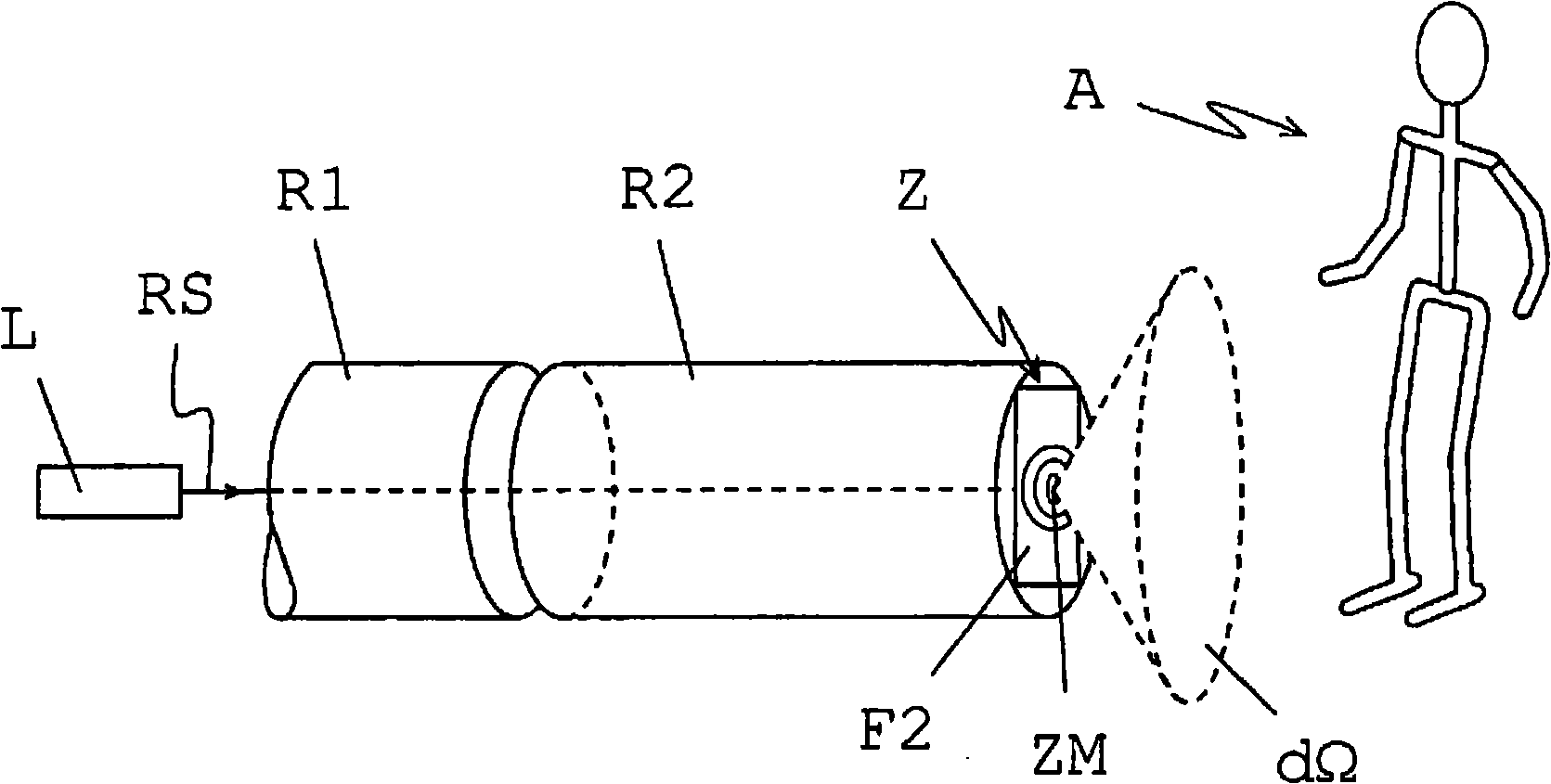

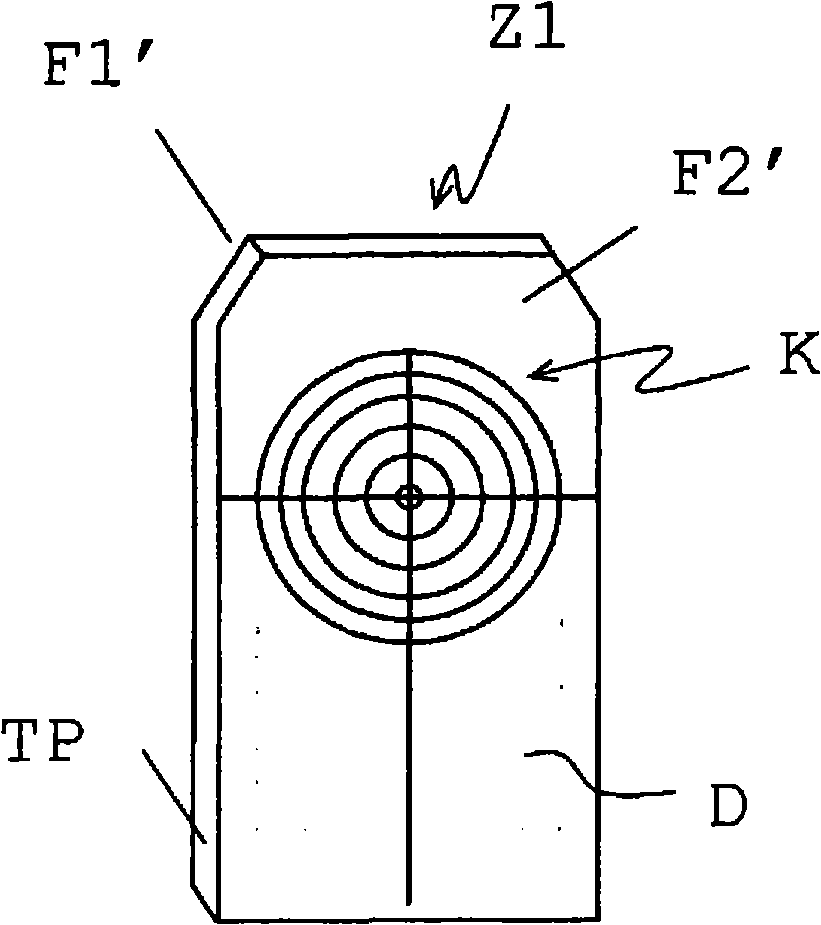

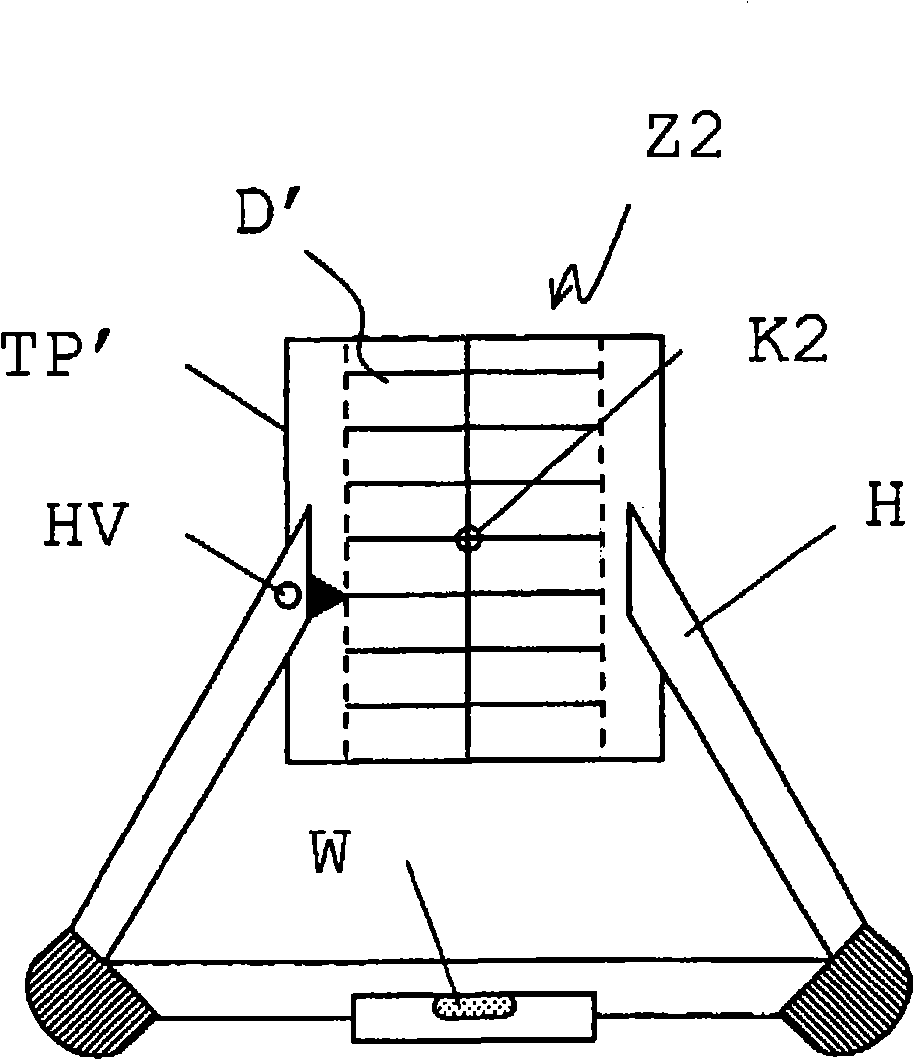

[0050] figure 1 A system comprising a target plate Z in pipe laying according to the invention is represented. The pipe laser L as radiation source emits a reference beam RS along the longitudinal axis of the first pipe R1 already laid. The target plate Z according to the invention is fastened concentrically to the second pipe R2. The target plate Z has two surfaces: a first surface in the direction of the reference beam RS and inside the tube and a second surface F2 facing outside the second tube R2 and formed transparent to the reference beam, for example by opal glass or Colored plastic form. The position of the reference beam RS is shown on the second surface F2 of the target plate Z. In this example, the rectangular target plate Z has polar coordinates, that is, a plurality of concentric circular marking lines symmetrically around the midpoint of its surface, and since the arrangement is concentric with the pipe, symmetrical with respect to the pipe axis, the polar coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com