Vibrating transmitter for consistency measurement

A transmitter and consistency technology, applied in measuring devices, non-electric variable control, instruments, etc., can solve problems such as endangering measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention is based on the rapid frequency oscillation of the measuring body in the suspension, whereby the oscillation amplitude will vary depending on the fiber consistency of the suspension. This amplitude will be an inverse function of the fiber consistency and after signal processing the amplitude can be calculated and presented as an output signal of the measured consistency.

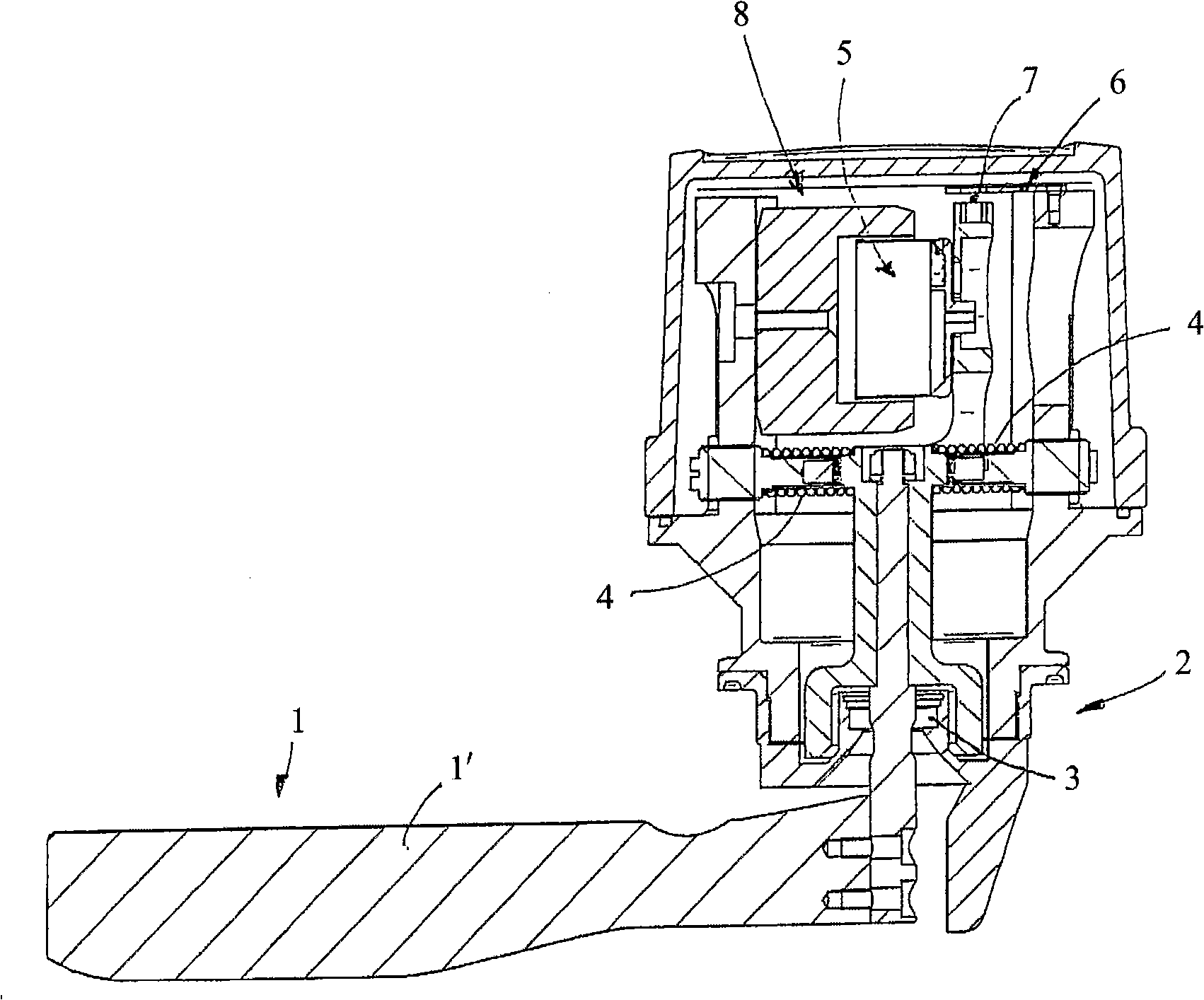

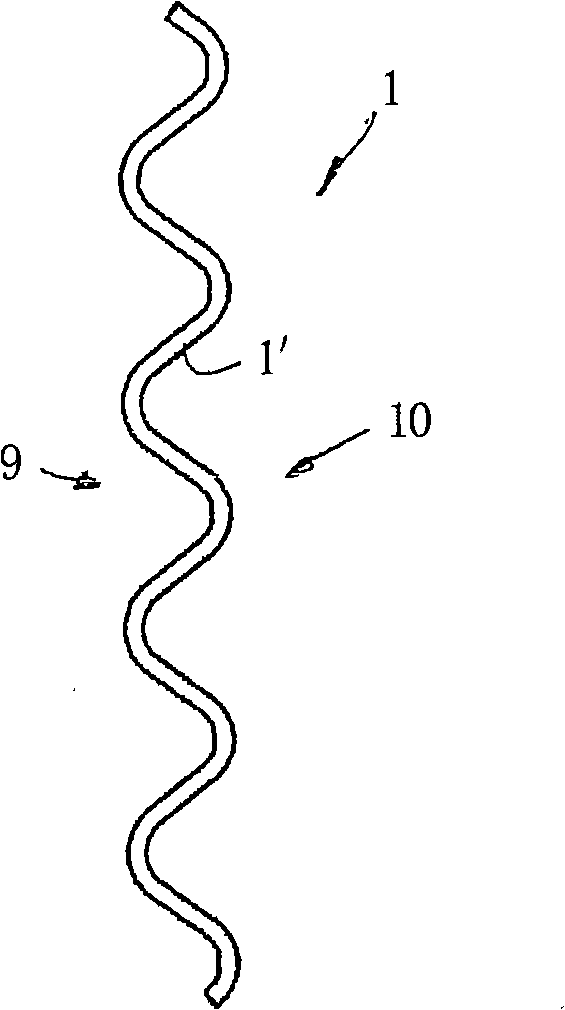

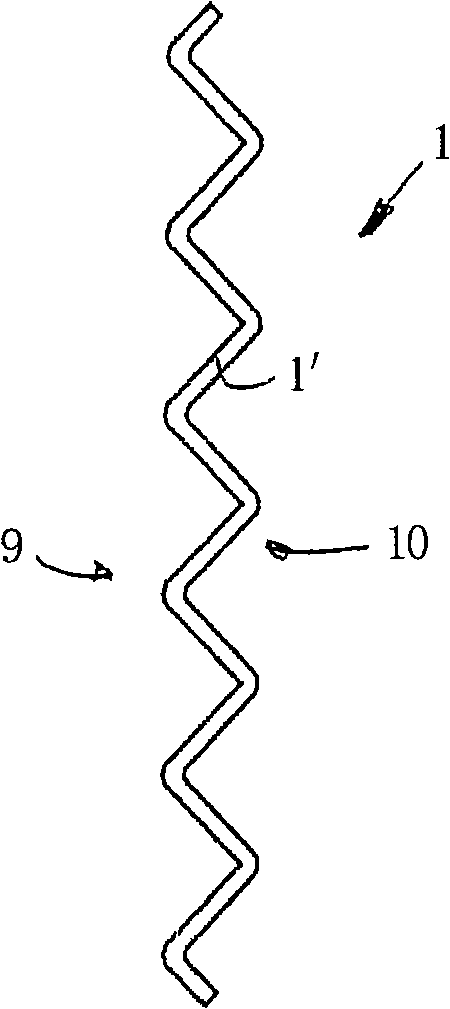

[0015] Such as figure 1 As shown, a measuring body 1 in the form of a vane 1 ′ inserted into the suspension is suspended in a bearing system 2 and an elastic seal 3 . The measuring body is further positioned by means of an opposing spring system 4 and an excitation system with coils and magnets 5 . In the self-resonance range of 30-60 Hz typical for the device, a stationary applied sinusoidal current from the electrical operating device 6 causes the measurement volume to oscillate. The amplitude is measured with the linear position detection sensor 7 and is calculated and presented as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com