Compression-resistant fire-prevention risk-avoiding storage cabinet

A storage cabinet and risk-avoiding technology, applied in the field of pressure-resistant fire-proof and risk-avoiding storage cabinets, can solve the problems of unable to meet the short-term survival of personnel, unable to protect personnel safety, unable to withstand large gravity, etc., to prolong the effective rescue time and light weight. , functional and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

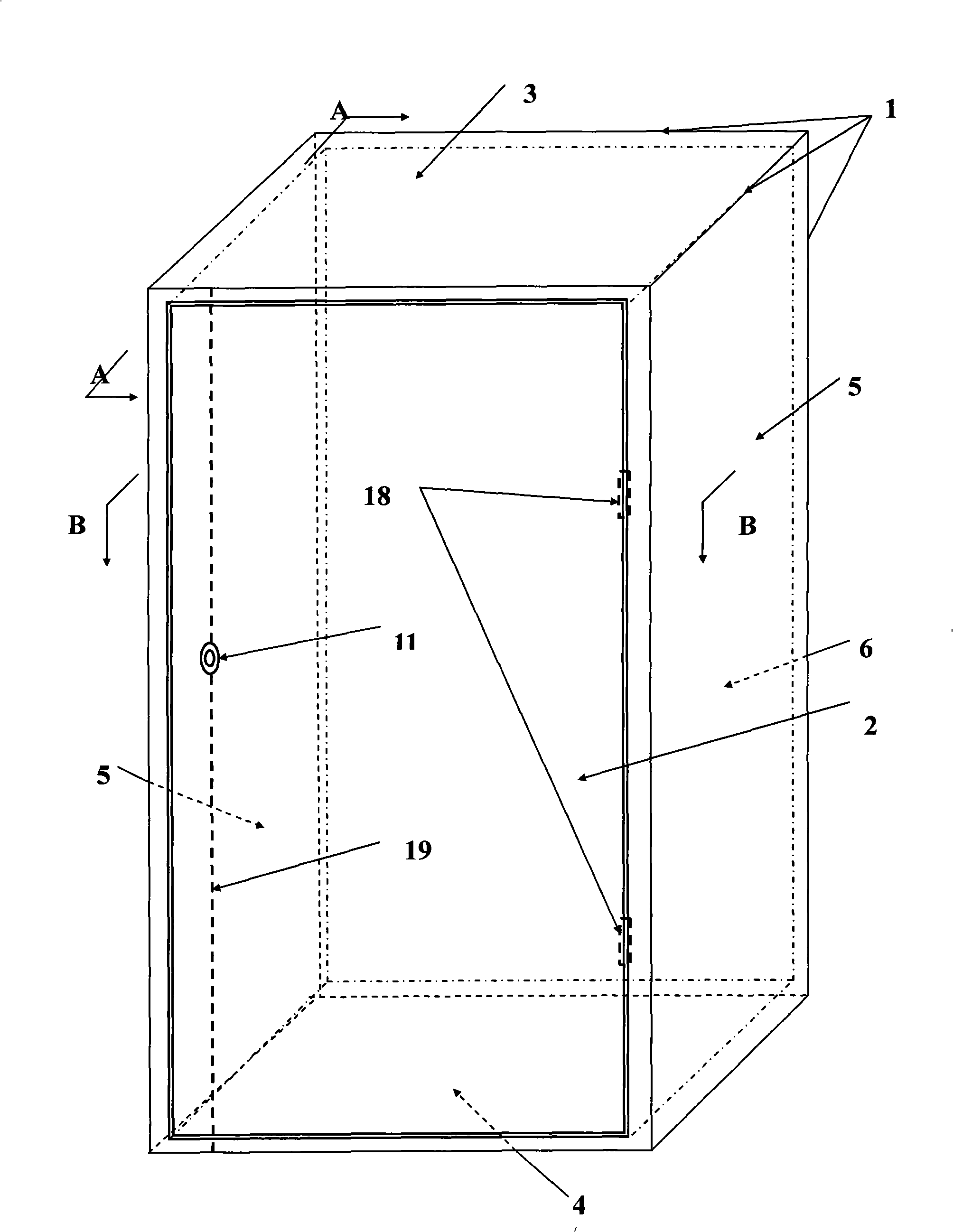

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

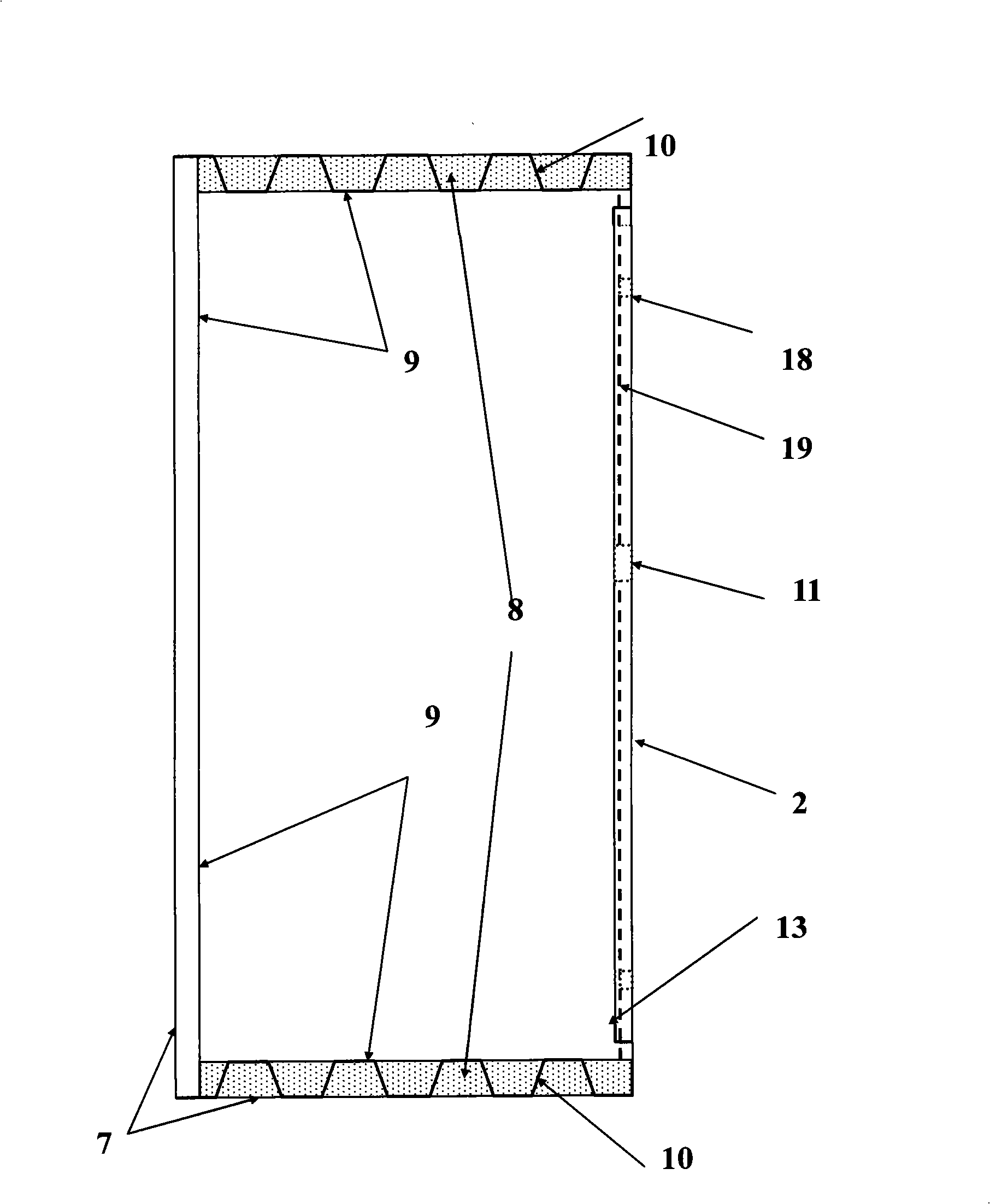

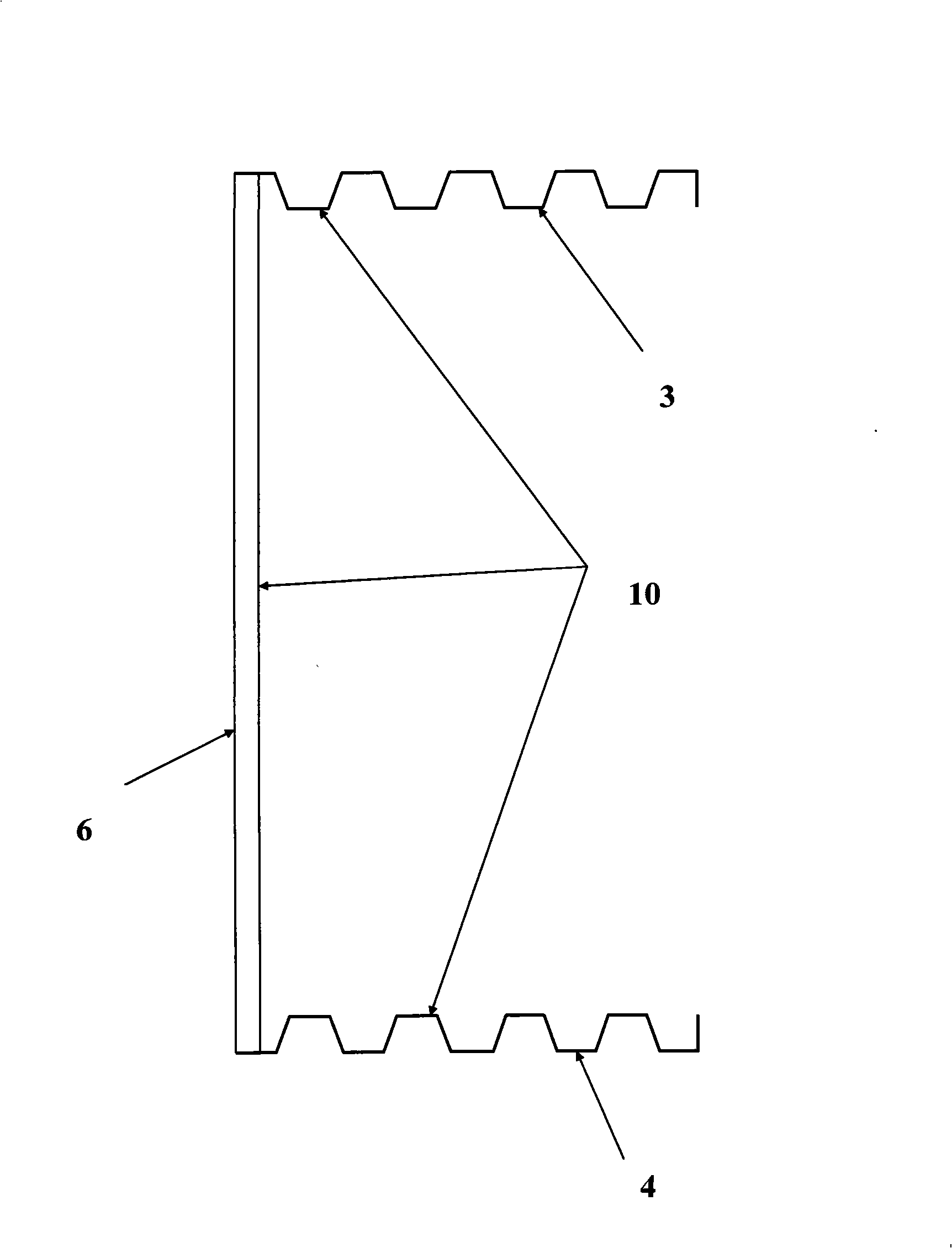

[0041] like figure 1 , figure 2 , image 3 , Figure 4 , a kind of anti-pressure and fire-proof storage cabinet, comprising a cabinet frame 1 composed of a top board 3, a bottom board 4, two side boards 5, and a back board 6; The top board 3 , the bottom board 4 , the side boards 5 , the back board 6 and the door board 2 are all made of corrugated steel plates 10 . An exterior panel 7 is fixed outside the corrugated steel plate 10 . The cavity formed between the corrugated steel plate 10 and the exterior panel 7 is filled with a fireproof filling material 8 .

[0042] An interior trim panel 9 is fixed inside the corrugated steel plate 10 . The cavity formed between the corrugated steel plate 10 and the interior panel 9 is filled with a fireproof filling material 8 .

[0043] Figure 5 It is a cross-sectional view of another embodiment of the corrugated steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com