Conveyor

A conveyor and conveying direction technology, applied in the field of conveyors, can solve problems such as production stagnation and product damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

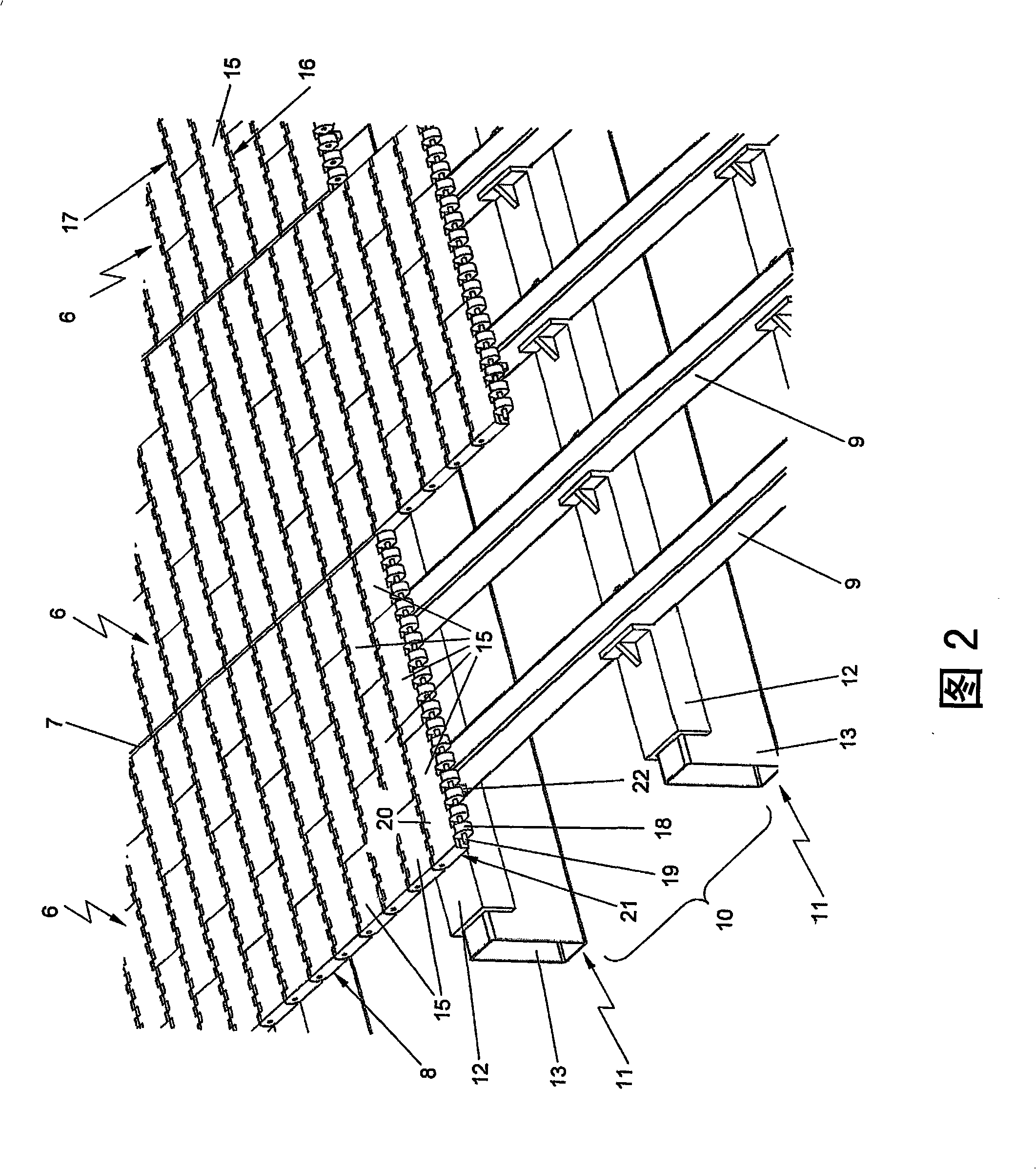

[0019] The drawings are merely schematic representations of preferred embodiments of the invention, given by way of non-limiting implementation. In the drawings, the same or corresponding parts are denoted by the same reference numerals.

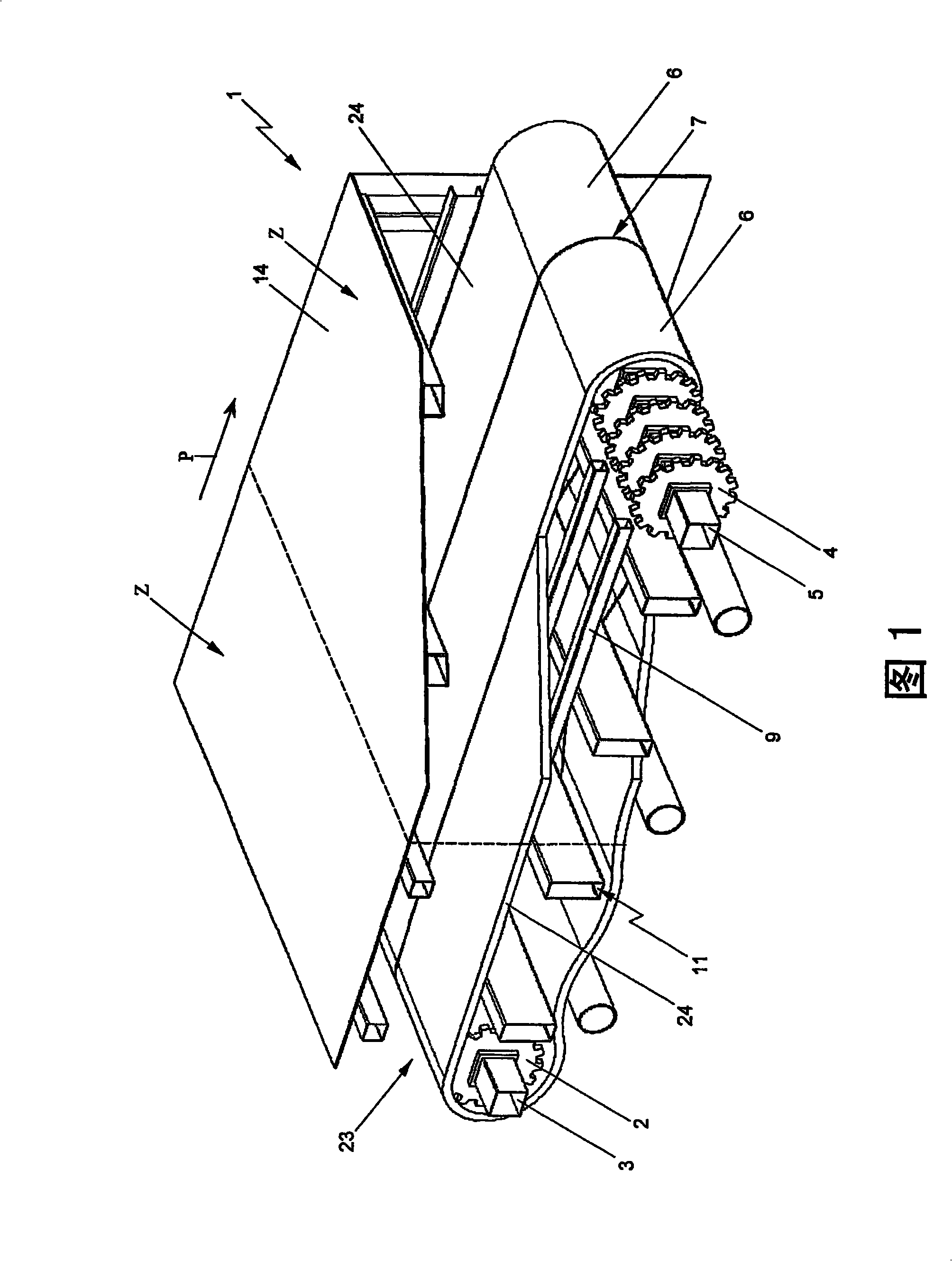

[0020] Figure 1 shows a conveyor 1 for conveying products along a conveying track with variable temperature. The conveyor 1 comprises a first axle 3 with deflecting wheels 2 and a second axle 5 with second deflecting wheels 4 . In the conveying direction indicated by the arrow P, a plurality of circulating conveying floors 6 run side by side in parallel around the first and second deflection wheels 2 , 4 . At the same time, the conveying floor defines an unobstructed conveying surface. As explained further below, the conveyor floor 6 is of modular design with plastic floor modules 15 . In this case, the width of the modular base plate 6 is approximately 400 mm. Between adjacent conveyor floors 6 there is an intermediate space 7 of approx...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com