Film overlay device of shoe cover machine and film overlay method using the device

A film covering device and shoe cover machine technology, which is applied in the field of shoe cover machines, can solve the problems of inability to achieve reliable wrapping of heat shrinkable film, low working efficiency of automatic shoe cover machines, and unsatisfactory heat shrinkable film wrapping effects, etc., to achieve improved coverage Film effect and speed, reduce heat loss, fast film covering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

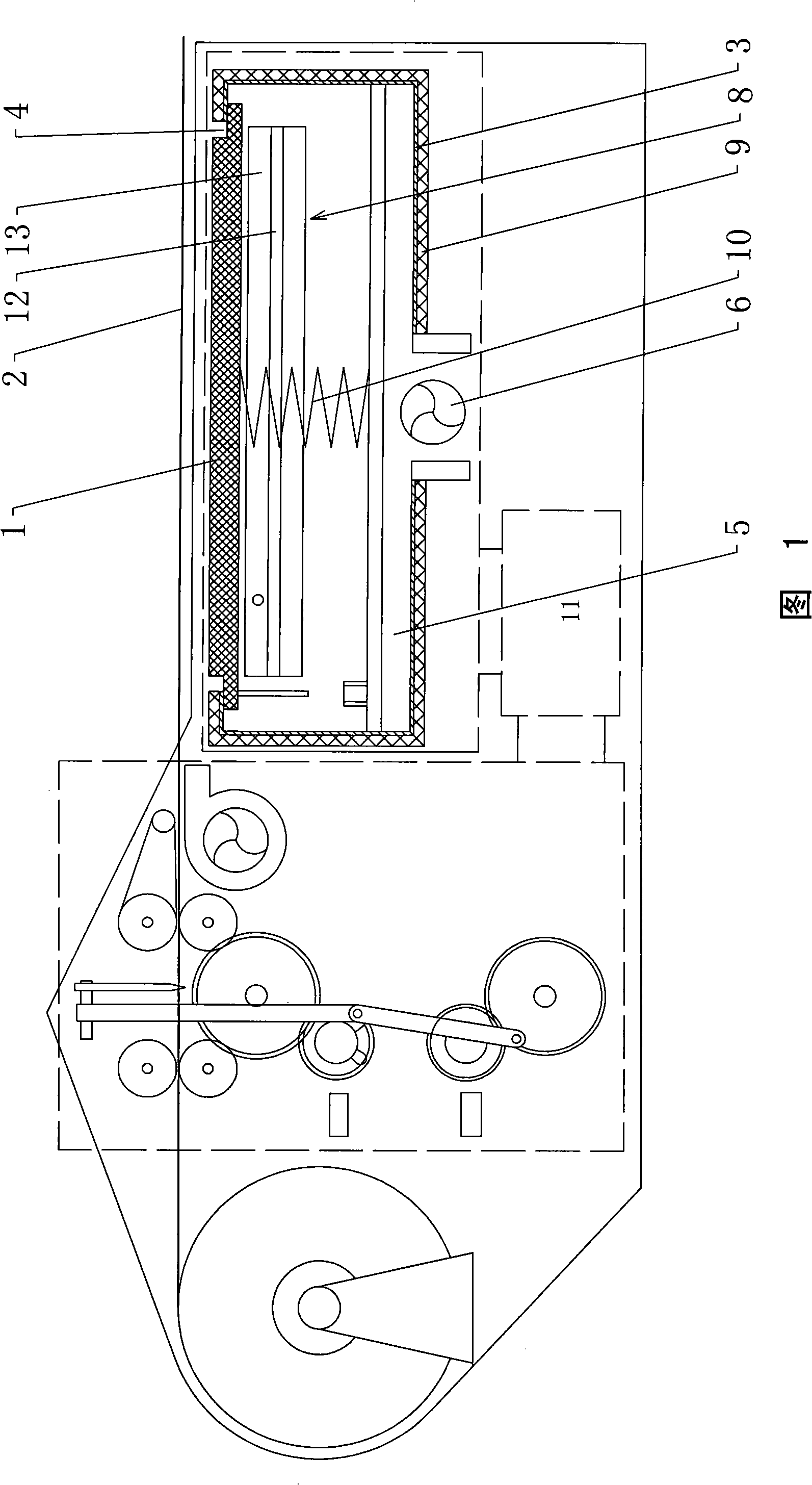

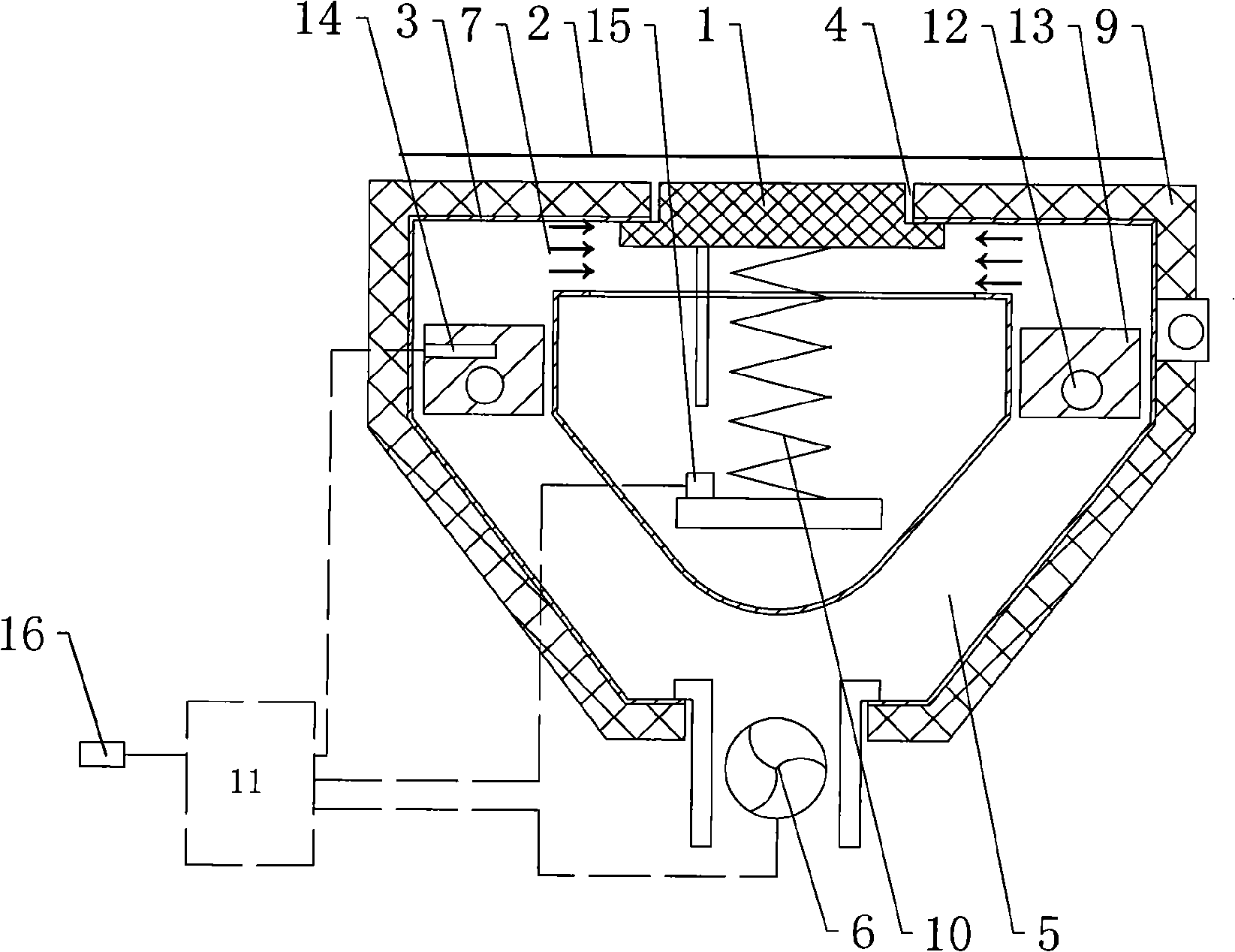

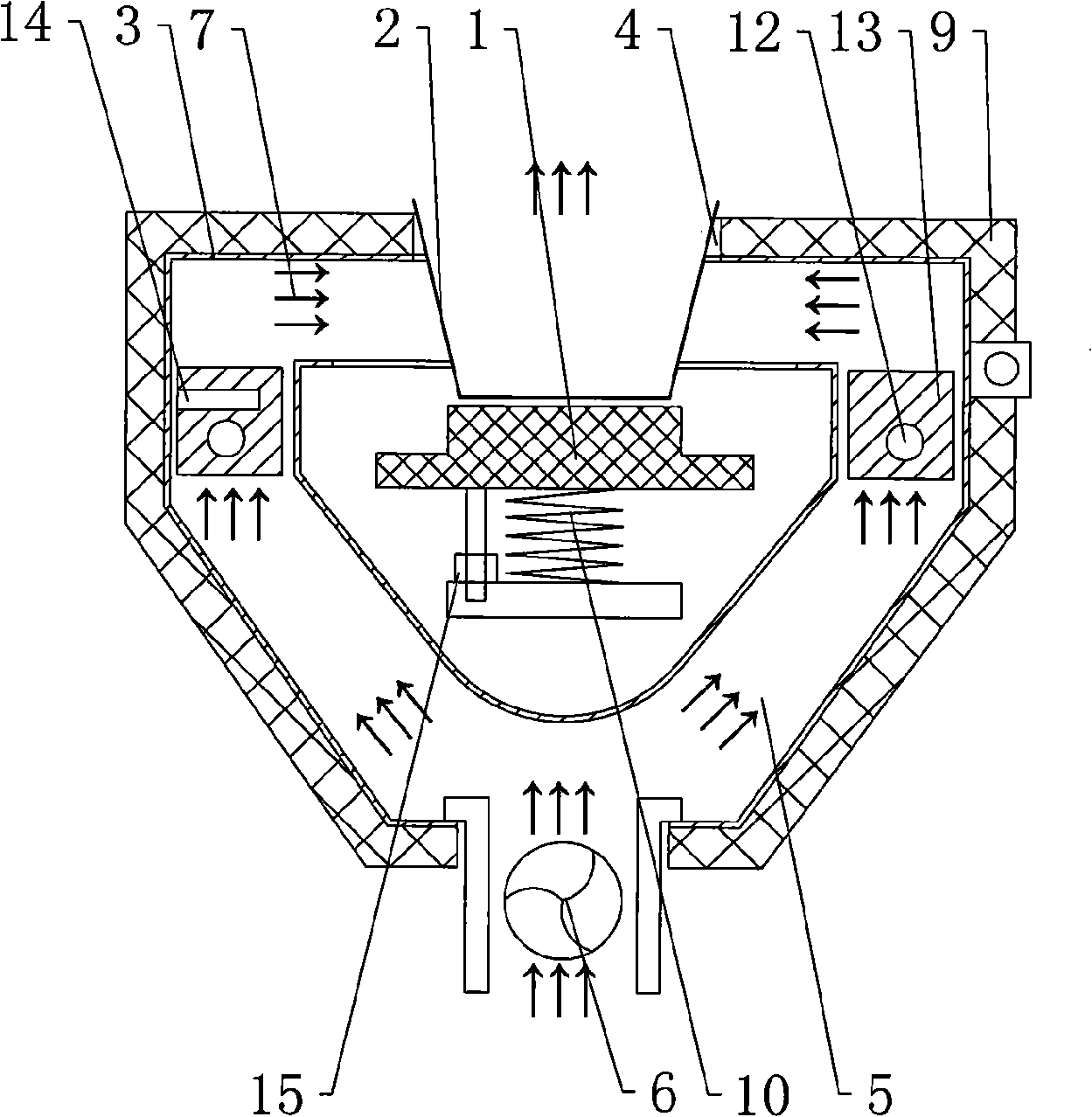

[0027] Combined with Figure 1, figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown: the shoe cover machine film coating device of this embodiment includes: a heating device is provided under the pedal 1, and the heat shrinkable film 2 is transported to the top of the pedal. The heating device includes a hot air chamber 3, the pedal 1 closes the outlet 4 of the hot air chamber, the hot air chamber is provided with a hot air duct 5, the air inlet of the hot air duct is provided with a fan 6, and the hot air duct The air outlet 7 is located on both sides of the pedal length direction. A heater 8 is provided in the hot air duct, a heat insulating layer 9 is provided outside the hot air chamber, and a reset device is provided in the pedal lifting mechanism, and the reset device is a spring 10 located at the bottom of the pedal. The control system 11 controls the fan 6 and the temperature of the hot air in the hot air chamber. The heater includes: a heating body 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com