Straight wing cycloid thruster with stepping motor as controlling mechanism

A technology of cycloid propeller and stepper motor, which is applied in the direction of rotary propeller, ship propulsion, propulsion components, etc., can solve the problems of complex control mechanism, slow dynamic response, short service life, etc., and achieve simplified control system structure, Effect of prolonging service life and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

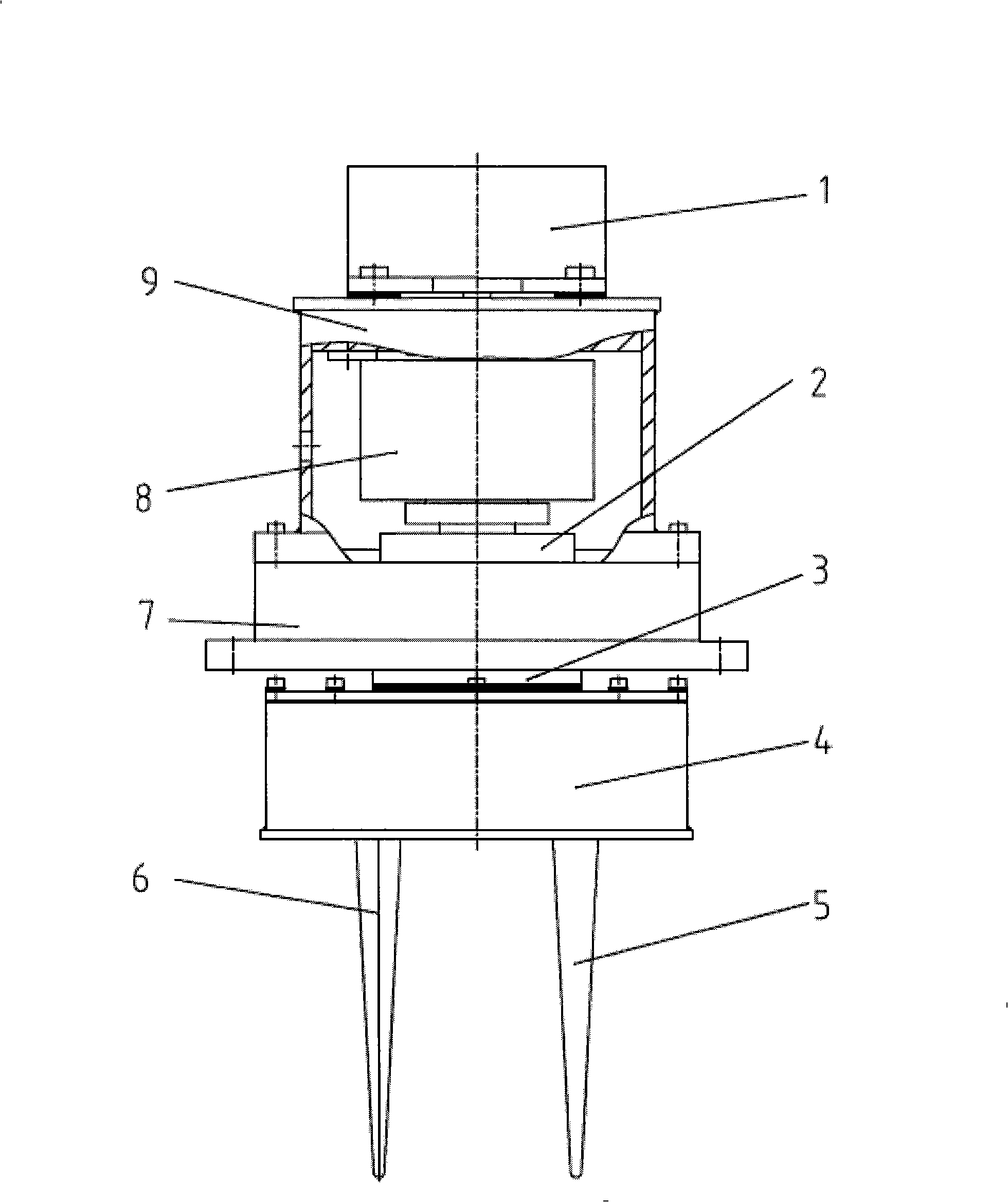

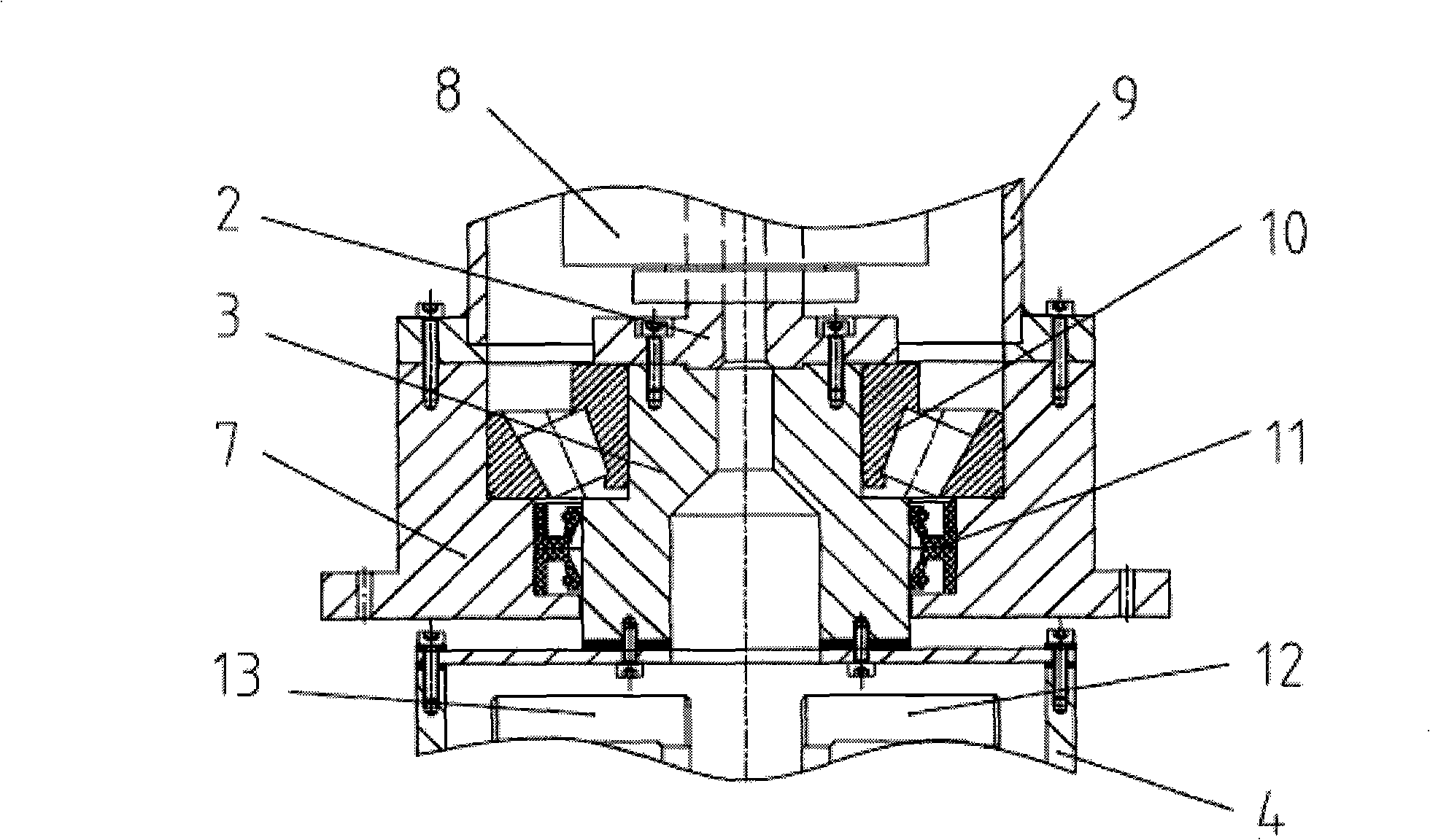

[0018] Such as figure 1 As shown, the straight-wing cycloidal propeller with a stepping motor as the control mechanism is provided with a main motor installation bracket 9 on the installation base 7, and the main motor installation bracket 9 is provided with a main drive motor 1, and the main drive motor 1 is connected to The shaft 2 is connected with the main shaft 3, the connecting shaft 2 is covered with a conductive ring 8, the main shaft 3 is connected with the rotary box 4 below the installation base 7, and the rotary box 4 is provided with a first blade control motor 12 and a second blade control motor 13 , the first blade control motor 12 is connected to the first blade 5 , and the second blade control motor 13 is connected to the second blade 6 .

[0019] Such as figure 2 As shown, a tapered roller bearing 10 and a plurality of lip seal rings 11 are provided between the main shaft 3 and the installation base 7 .

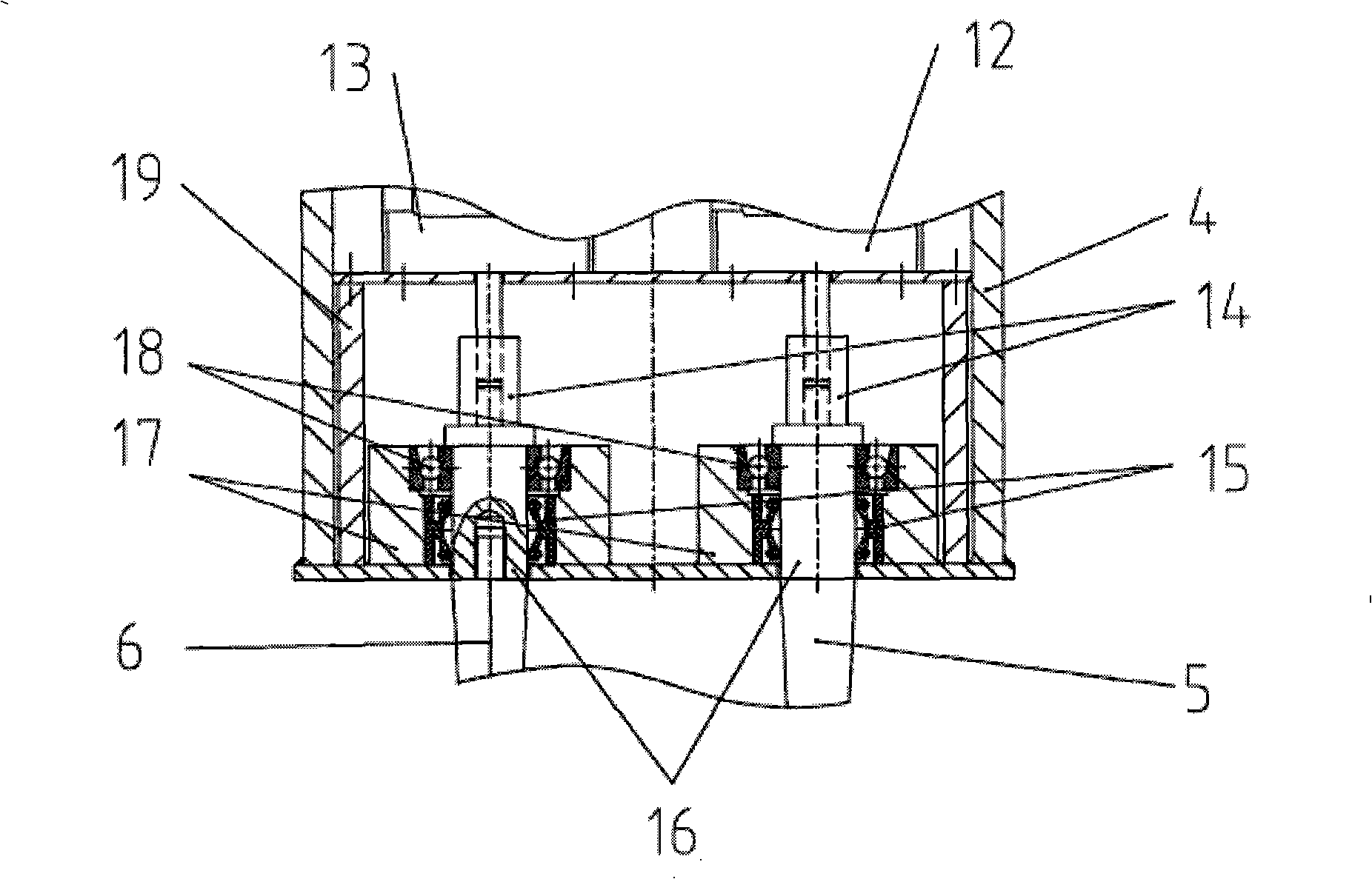

[0020] Such as image 3 As shown, the bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com