Dry method red mud storage yard drainage method and apparatus having forced drainage function

A drainage device, red mud technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of complex construction process, small drying and consolidation effect, poor permeability, etc., to reduce construction area and cost, shorten dry The effect of curing and consolidation cycle, which is beneficial to its own stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

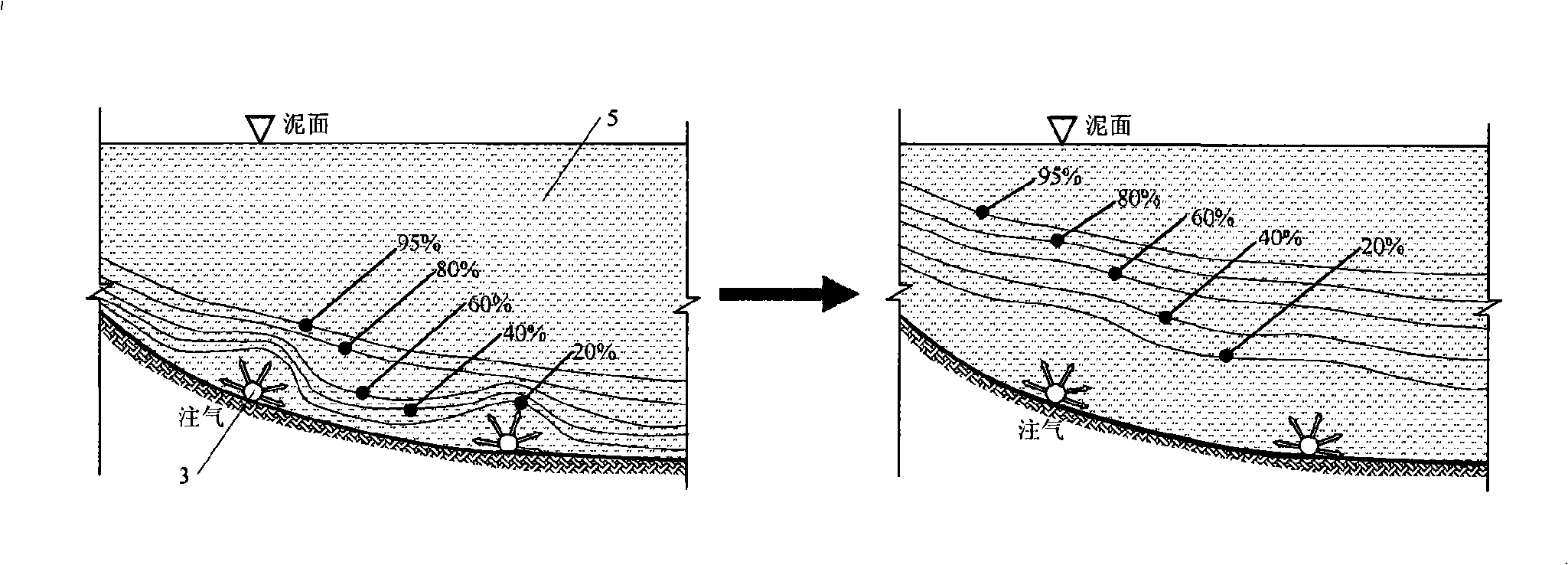

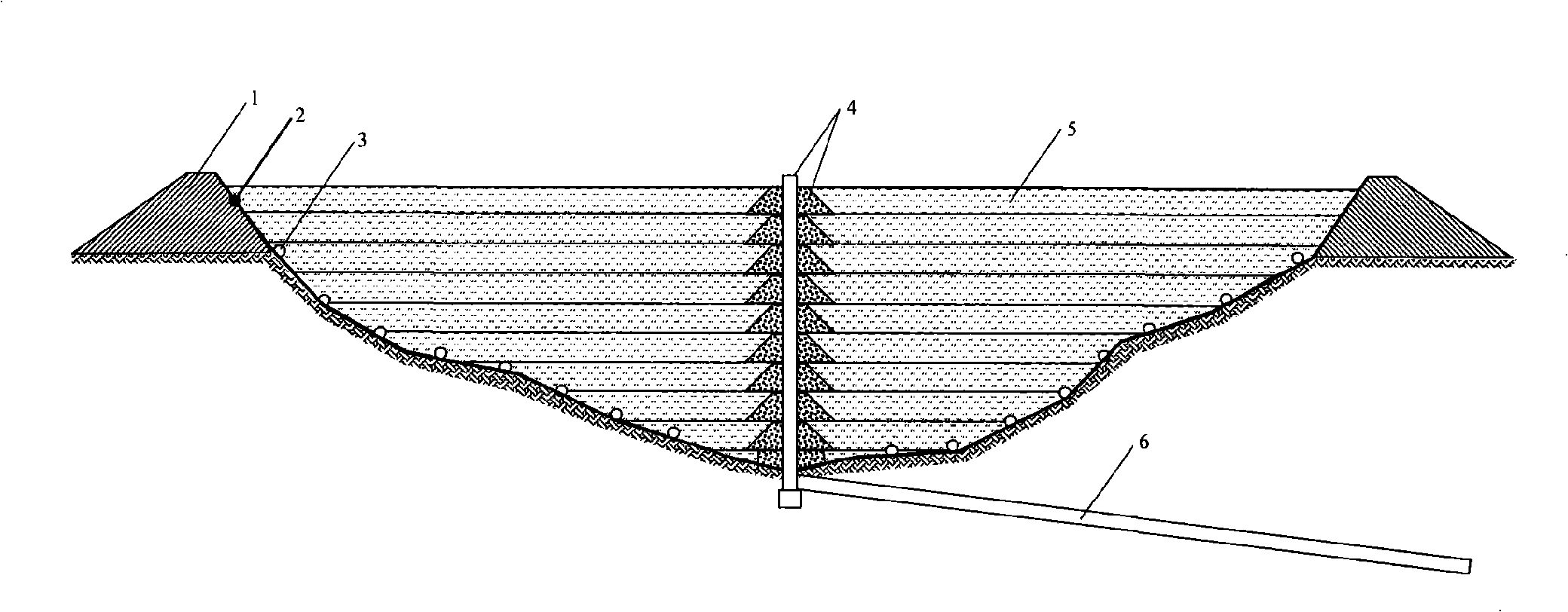

[0013] figure 1 It is a principle diagram of forced drainage of the present invention. The gas supply pipeline 3 buried at the bottom of the red mud 5 yard can continuously inject pressure gas into the red mud. The pressure gas is provided by an air compressor and its pressure is controlled to be 0.6 to 5.0 of the vertical earth pressure at the position of the pipeline. times. As the pressure gas gradually enters the red mud soil body from the bottom of the stockyard, under the action of the pressure gradient field formed by the gas, the gas will continue to spread around and rise continuously. Therefore, the water-saturated red mud soil will gradually dehydrate and become unsaturated soil, and its water content will continue to decrease with the entry of gas, and its saturation contour will gradually move away from the gas supply pipeline. At the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com