Horizontal type fabric cutting machine

A cloth cutting machine, horizontal technology, applied in the cutting of textile materials, textiles and papermaking, tire parts and other directions, can solve the problem of low cloth cutting efficiency, and achieve the effect of avoiding invalid consumption and improving cloth cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

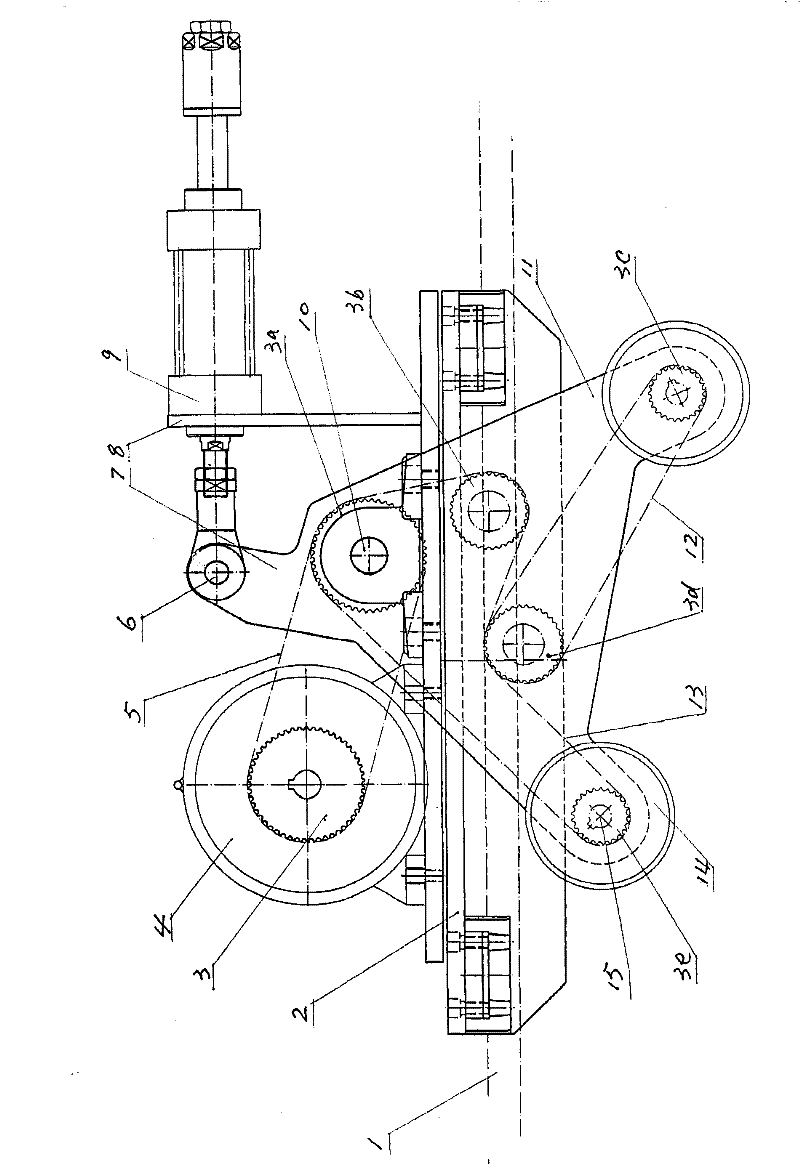

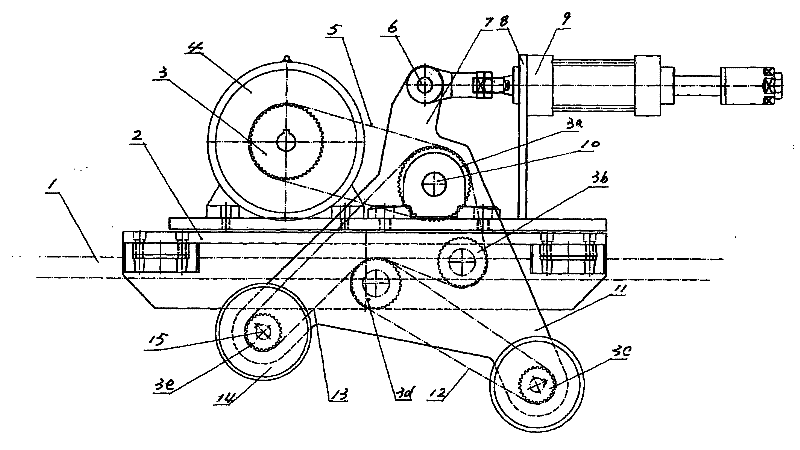

[0012] As shown in the accompanying drawings, the horizontal cloth cutting machine of the present invention includes a slideway 1 on which a base 2 that can move horizontally along the slideway 1 is arranged. The base 2 is provided with a motor 4 , a support shaft 10 and a stroke adjustment cylinder 9 , the output shaft of the motor 4 is parallel to the support shaft 10 and they are all perpendicular to the motion direction of the base 2 .

[0013] One side of the base 2 is provided with a support frame 11, which is an isosceles triangle, one corner, that is, the top angle, is rotatably hinged on the support shaft 10, and the other two corners protrude under the base 2. Among them, the upper boss 7 is processed on the corner where the support frame 11 cooperates with the support shaft 10, the stroke adjustment cylinder 9 is fixed on the machine base 2 through the bracket 8, and the piston rod passes through the pin shaft 6 and the upper part of the support frame 11 corner. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com