Method for synthesizing nu-88 molecular sieve

A technology of NU-88 and molecular sieve, which is applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve energy and material consumption, high cost and high consumption of double quaternary ammonium salt template agent Time and other issues, to avoid waste and ineffective consumption, to overcome the incomplete reaction of raw materials, to avoid the effect of time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Under stirring conditions, mix 21.093g of 1-methylpyrrolidine and 23mL of absolute ethanol, and then add 26.88g of 1,6-dibromohexane dropwise to the above mixture at a rate of 3 drops / second. The pre-reaction was performed for 4 hours to obtain the pre-reaction product A1. The molar ratio of 1,6-dibromohexane, 1-methylpyrrolidine and solvent ethanol was 1:2.25:3.66.

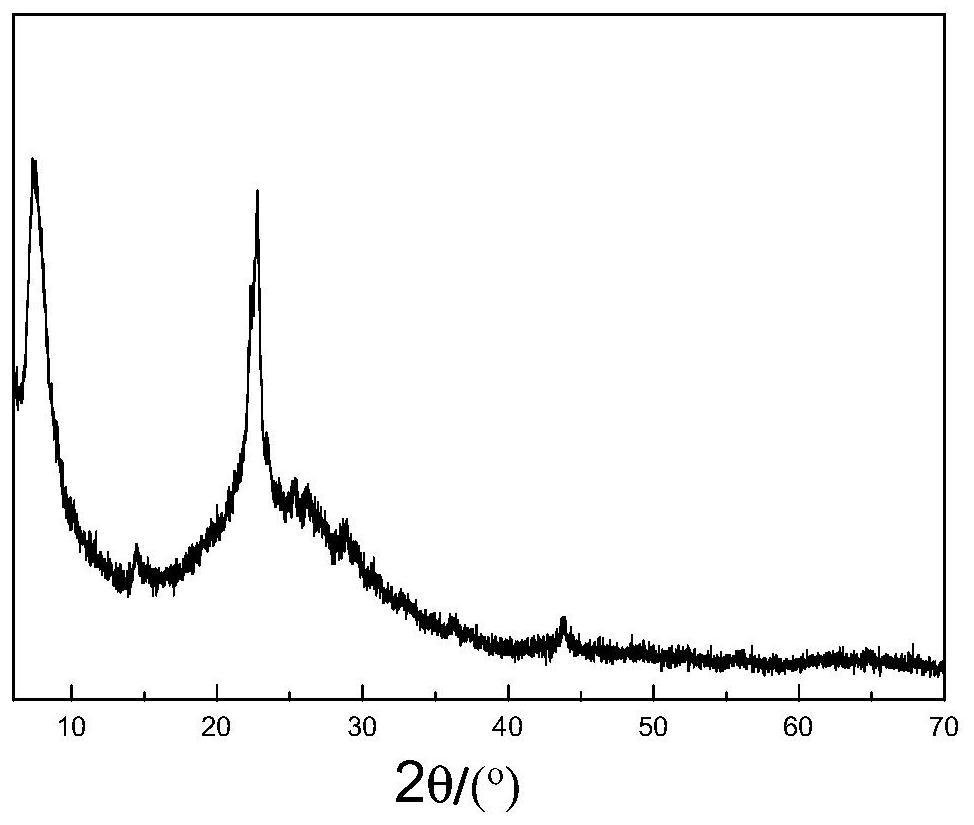

[0062] The pre-reaction product A1, 16.115g NaAlO 2 solution, 14.8g of 30% by weight NaOH solution was dissolved in an appropriate amount of deionized water, mixed uniformly, and under stirring conditions, 40g of white carbon black was slowly added to make a milky white colloidal mixture to be crystallized, and its molar composition was SiO 2 :Al 2 o 3 : Na 2 O:A1:H 2 O=100:3.3:16.7:16.7:5000, continue to stir for 1h, transfer to a 1L autoclave with mechanical stirring, stir at 160°C for hydrothermal crystallization for 13 days, stop the crystallization reaction, wash and filter the product Finally, d...

Embodiment 2

[0065] Synthesize NU-88 molecular sieve according to the method of Example 1, the difference is that under stirring conditions, 18.75g of 1-methylpyrrolidine and 32mL of ether were mixed, and then 26.875g of 1,6-dibromohexane was mixed with 5 drops / second Add it dropwise to the above mixture at a high speed, and pre-react at 35°C for 12 hours to obtain the pre-reaction product A2. The molar ratio of 1,6-dibromohexane, 1-methylpyrrolidine and solvent ether is 1:2:2.85 . The molecular sieve raw powder B2 was obtained by replacing A1 with the pre-reaction product A2. Its XRD spectrum was consistent with that of Example 1. The relative crystallinity and synthesis cost were calculated and listed in Table 1.

Embodiment 3

[0067] Synthesize NU-88 molecular sieve according to the method of Example 1, the difference is that, under stirring conditions, 19.69g of 1-methylpyrrolidine was mixed with 27mL of deionized water, and then 26.875g of 1,6-dibromohexane was mixed with 4 drops / Add it dropwise into the above mixture at a speed of 1 second, and pre-react at 60°C for 48 hours to obtain the pre-reaction product A3. The molar ratio of 1,6-dibromohexane, 1-methylpyrrolidine and solvent water is 1:2.1 : 13.89. The molecular sieve raw powder B3 was obtained by replacing A1 with the pre-reaction product A3. Its XRD spectrum was consistent with that of Example 1. The relative crystallinity and synthesis cost were calculated and listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com