LED tunnel lamp

A technology of LED tunnel light and LED light source, which is applied in the field of LED lighting, can solve the problems of ineffective heat dissipation of LED light source, complex structure, energy consumption, etc., achieve simple and convenient installation and fixing, improve luminous intensity, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

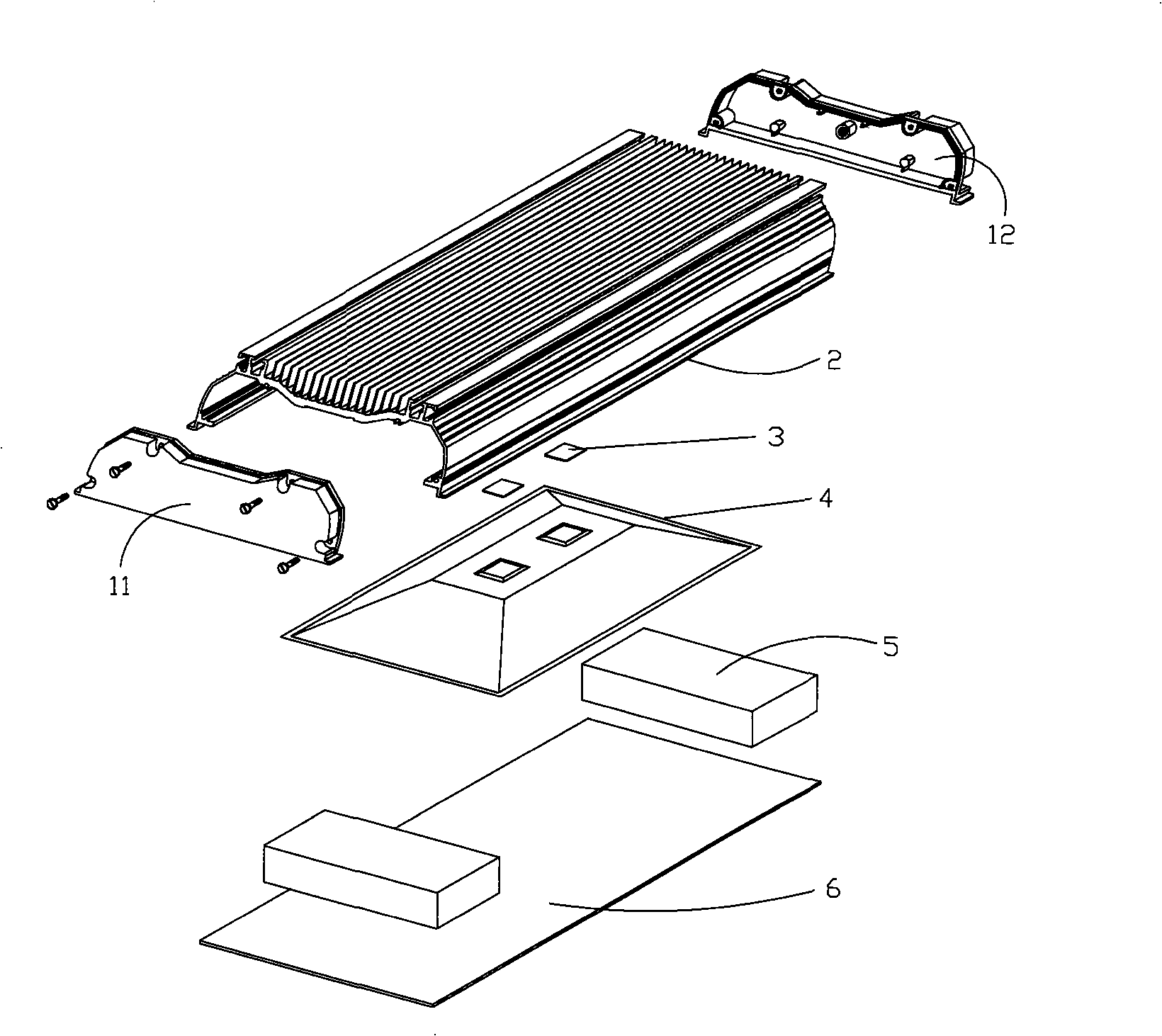

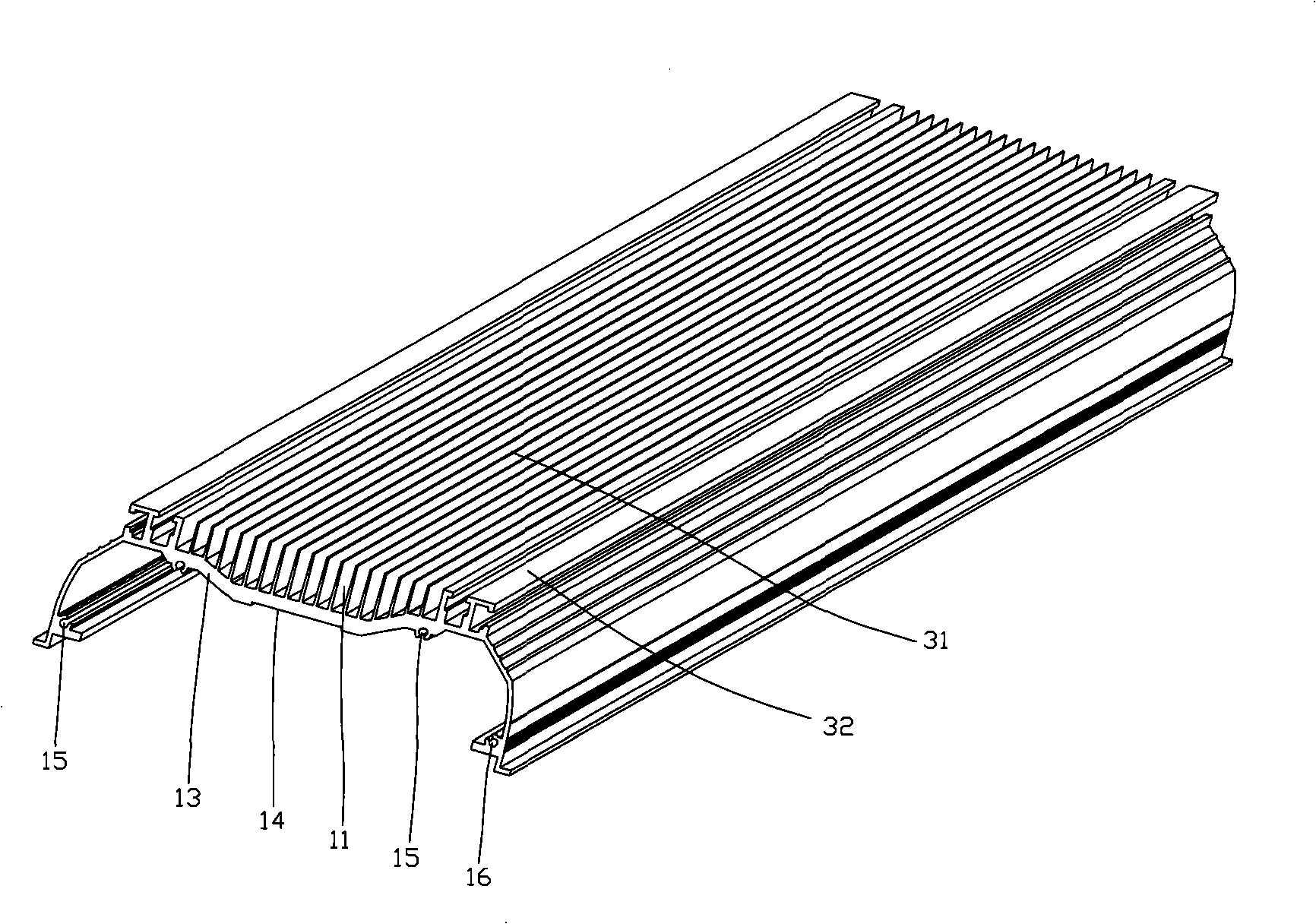

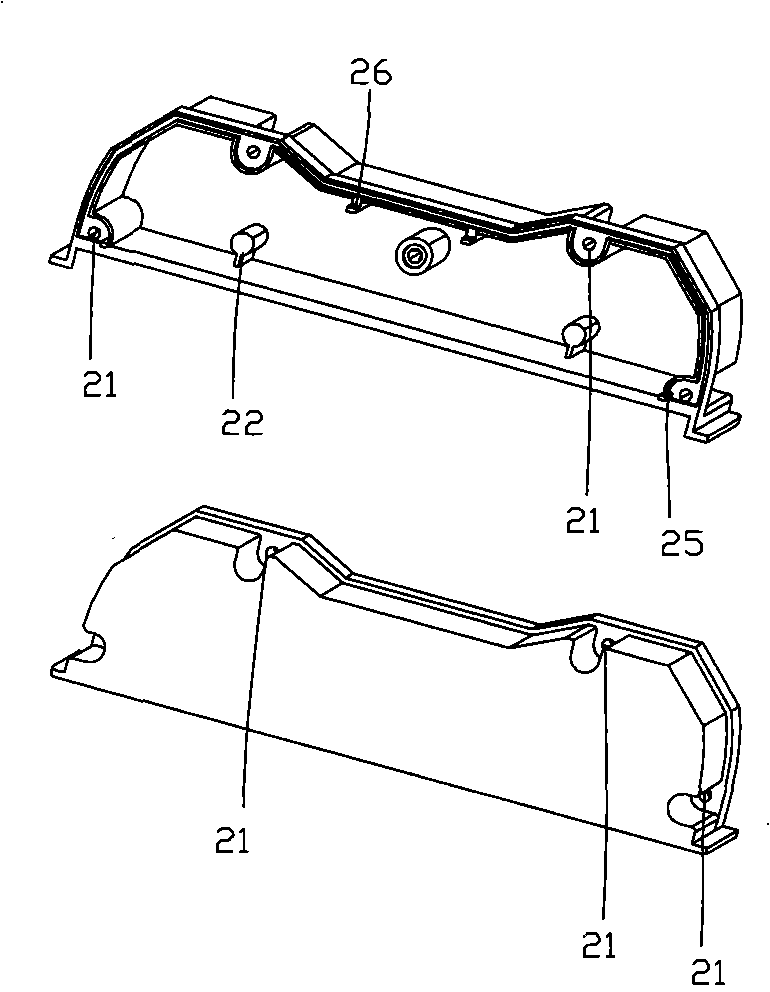

[0017] Example: such as figure 1 As shown, an LED tunnel light consists of a left side panel 11, a right side panel 12, an upper lamp housing 2, a flat transparent lampshade 6, at least one LED light source module 3 installed inside the upper lamp housing, and at least one LED light source The reflector 4 of the module mounting hole, the LED light source driver 5 with at least one positive and negative power supply output and the sealing ring (pad) are composed of the upper lamp housing 2 and the left and right side panels 11 and 12 are fixedly connected by screws (thereby can be filled with Sealing gasket, and sticking with glue to ensure sealing) to form the lamp housing, lamp housing and flat transparent lampshade 6 are fastened by buckles or screws, etc., wherein a sealing ring (pad) is filled, and glued together, lamp housing, sealing ring (pad) ) and the flat transparent lampshade 6 form a sealed cavity (waterproof and dustproof); the LED light source module 3 is fixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com