Mounting structure and mounting method of evaporator assembly

A technology of evaporator assembly and installation structure, which is applied in the direction of evaporator/condenser, refrigeration components, refrigerators, etc., and can solve the problems of not considering the influence of peripheral related parts, many fixed points, and a lot of time consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

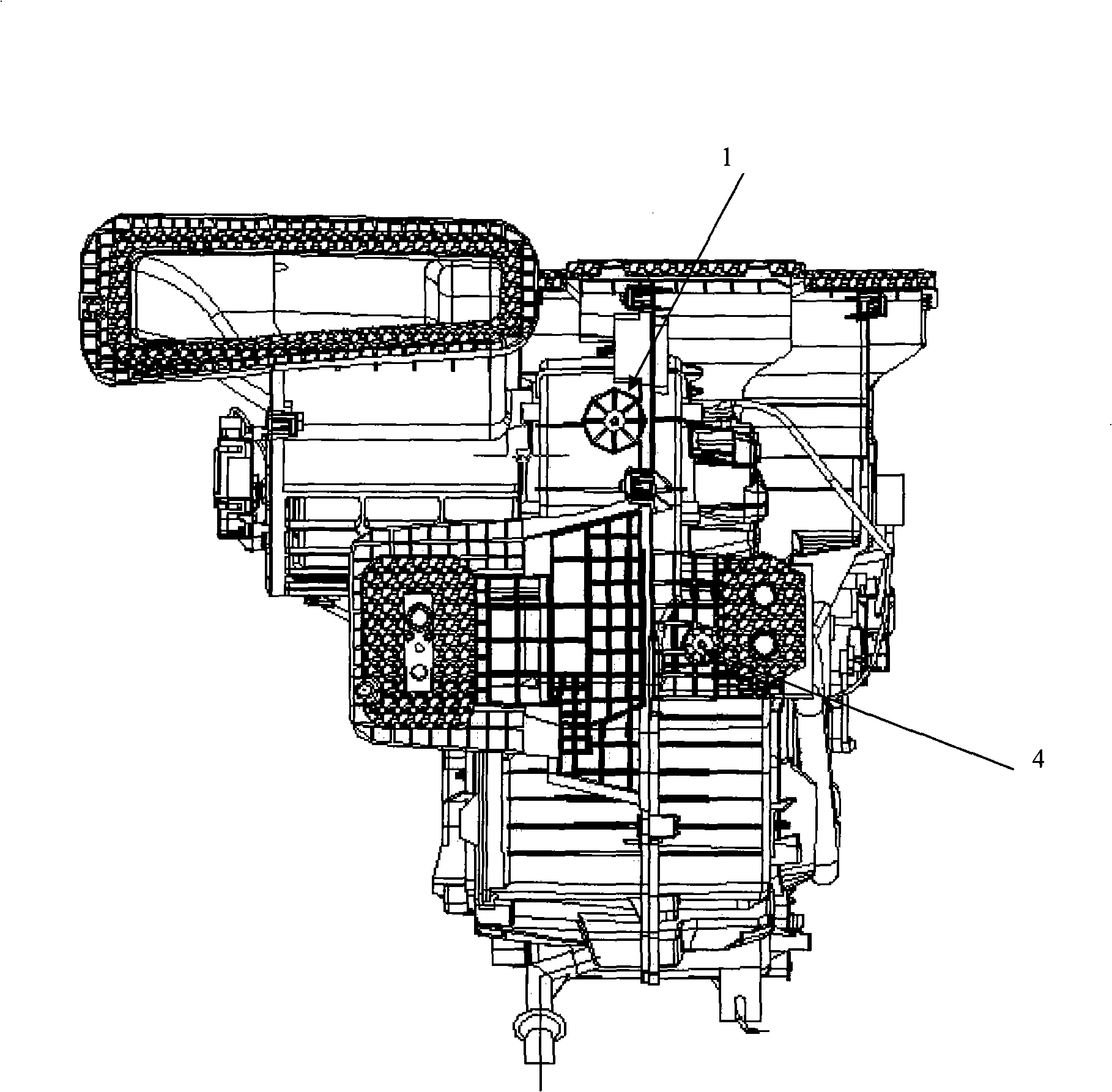

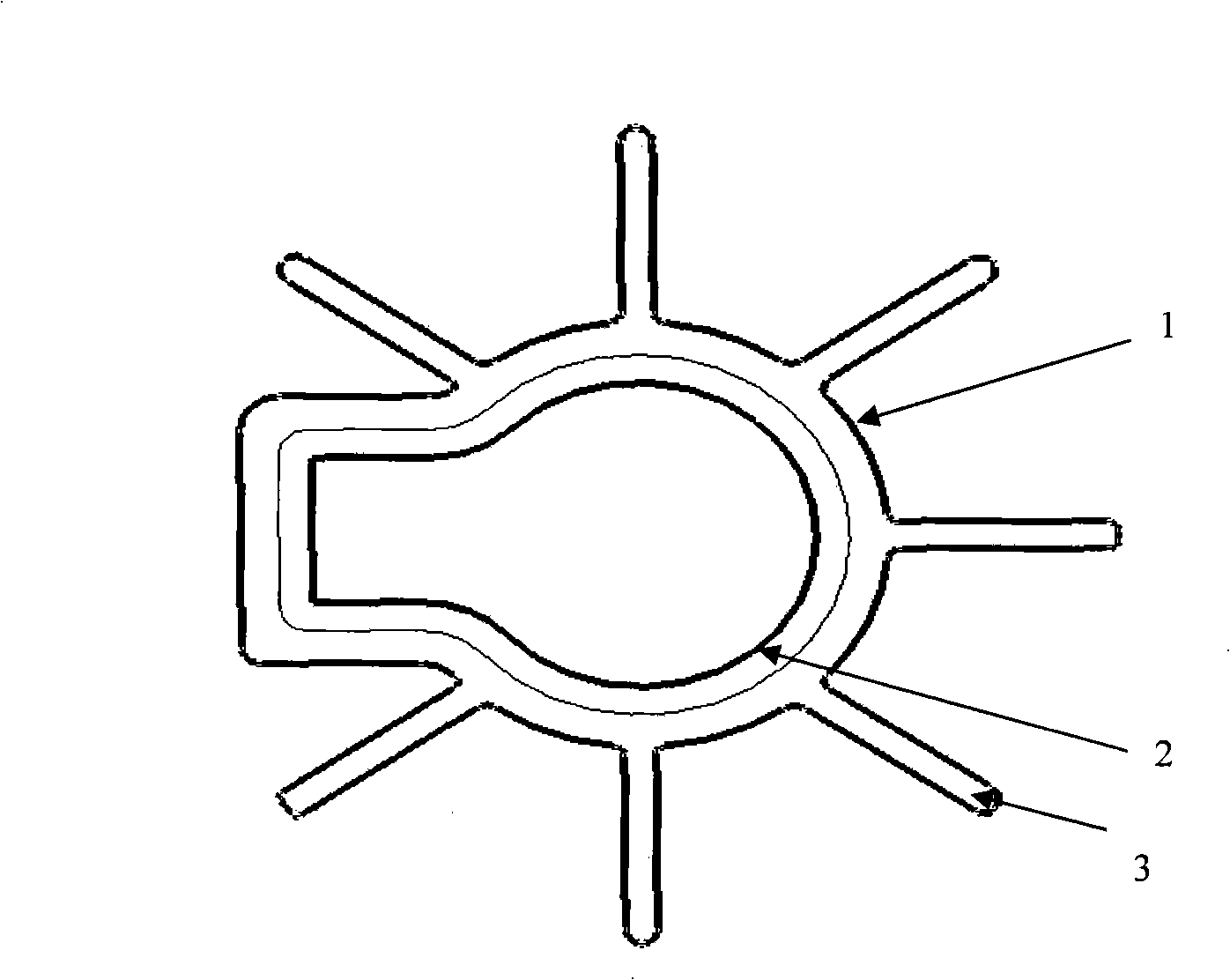

[0017] Such as figure 1 As shown, on the basis of the original symmetrical HVAC assembly, the structure of the fixed installation point 1 is changed. The installation point 1 is a hole 2, and the shape is a combination of square rows and circles. This point provides a fixed limit for the evaporator assembly. Adding a square shape can prevent the evaporator assembly from moving in the circumferential direction of the circular fixed point, restrict a certain degree of freedom, and better ensure the installation accuracy of the evaporator assembly. Its periphery has stiffener 3, specifically as figure 2 shown. Correspondingly, a boss protrudes from the front wall sheet metal used for installation, which is used for fixing and limiting the HVAC assembly.

[0018] On the HVAC assembly, at the lower part of the installation hole 1, there is also an adjustable installation point, which is a protrusion. Correspondingly, there is a image 3 The waist-shaped hole shown is used to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com