Liquid crystal display panel and method for making the same

A technology for liquid crystal display panels and substrates, which is applied in the photoengraving process, optics, optomechanical equipment and other directions of the pattern surface, which can solve the problems of complicated processes and high material costs, improve the allowable range, reduce costs, and reduce materials and processes. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

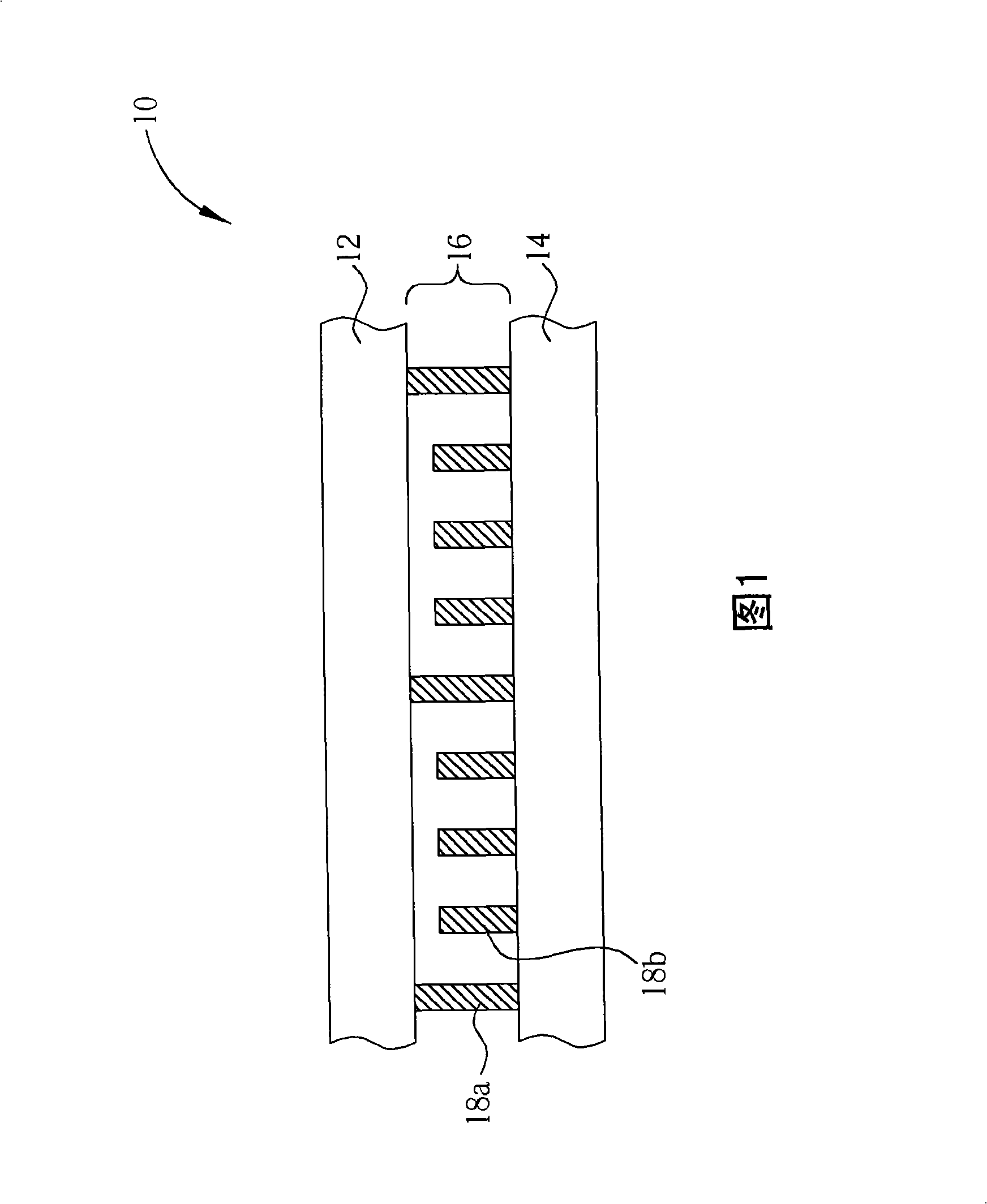

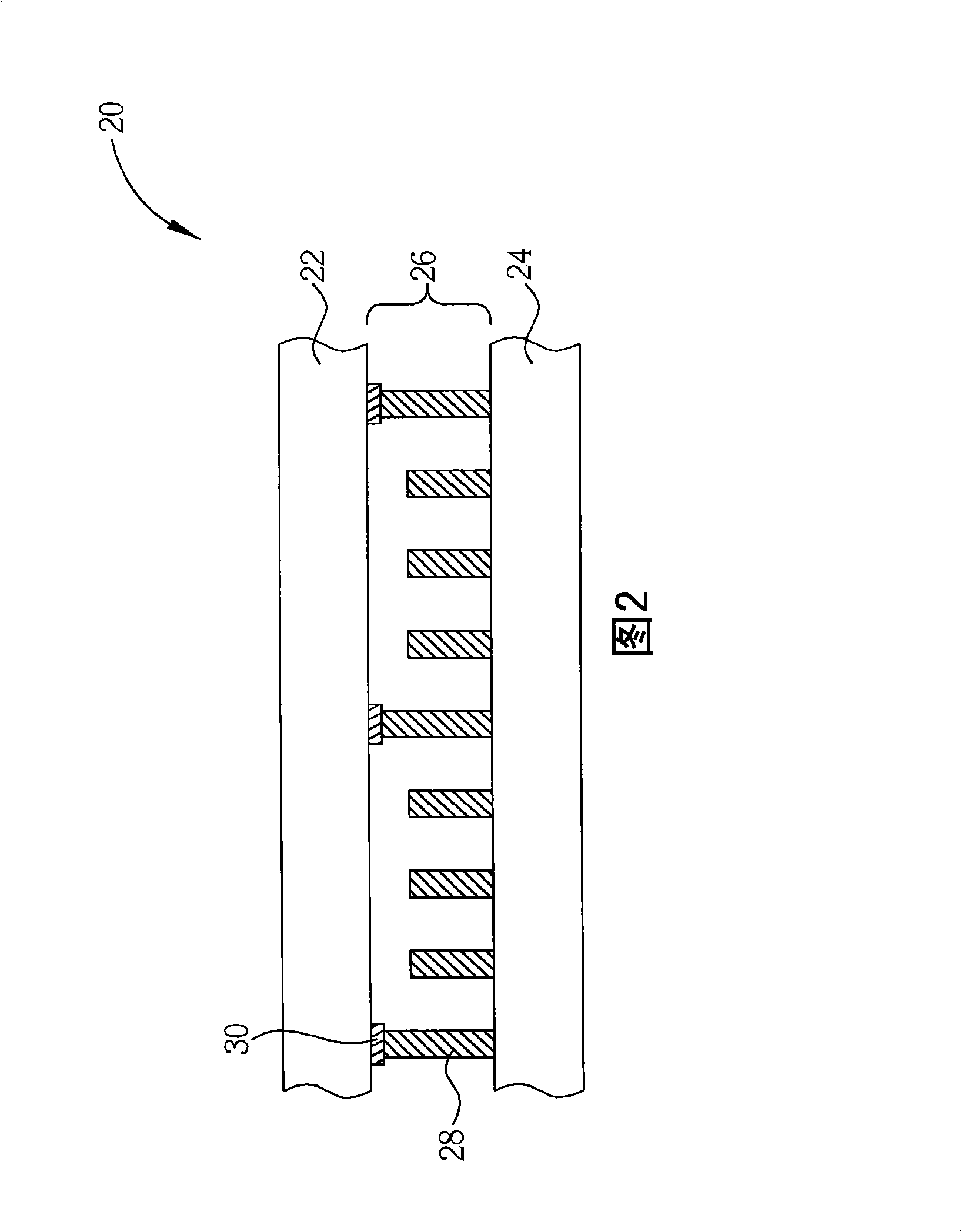

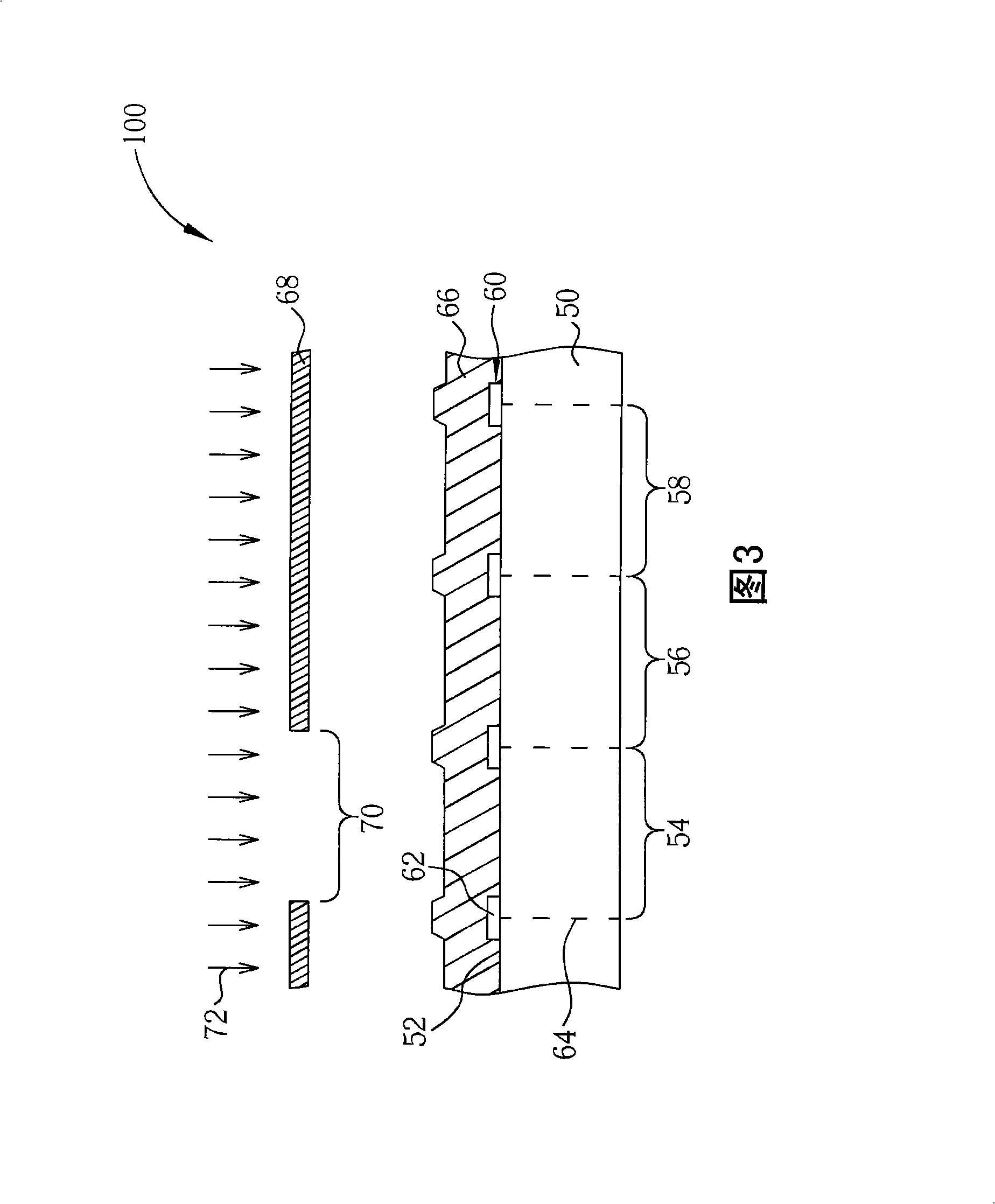

[0053] Please refer to FIGS. 3 to 8. FIGS. 3 to 8 are schematic cross-sectional views of the first embodiment of the method for manufacturing a liquid crystal display panel of the present invention. FIG. 3 is a partially enlarged schematic diagram of the first substrate 50 of the liquid crystal display panel 100 of the present invention. According to the manufacturing method of the present invention, first, a first substrate 50 is provided, which includes a plurality of first sub-pixel regions 54, a plurality of second sub-pixel regions 56, and a plurality of third sub-pixel regions 58, which are arranged adjacent to each other to form a matrix arrangement. The first sub-pixel area 54, the second sub-pixel area 56, and the third sub-pixel area 58 respectively represent sub-pixels that can provide light of different or the same color. Next, a patterned black matrix layer 60 is formed on the first surface 52 of the first substrate 50, which includes a plurality of black matrix patte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com