Non-contact switch apparatus

A switching device, non-contact technology, applied in electronic switches, electrical components, pulse technology, etc., can solve the problems of inability to switch quickly, insensitive to changes, etc., to prevent insensitive resistance changes and rapid switching operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings.

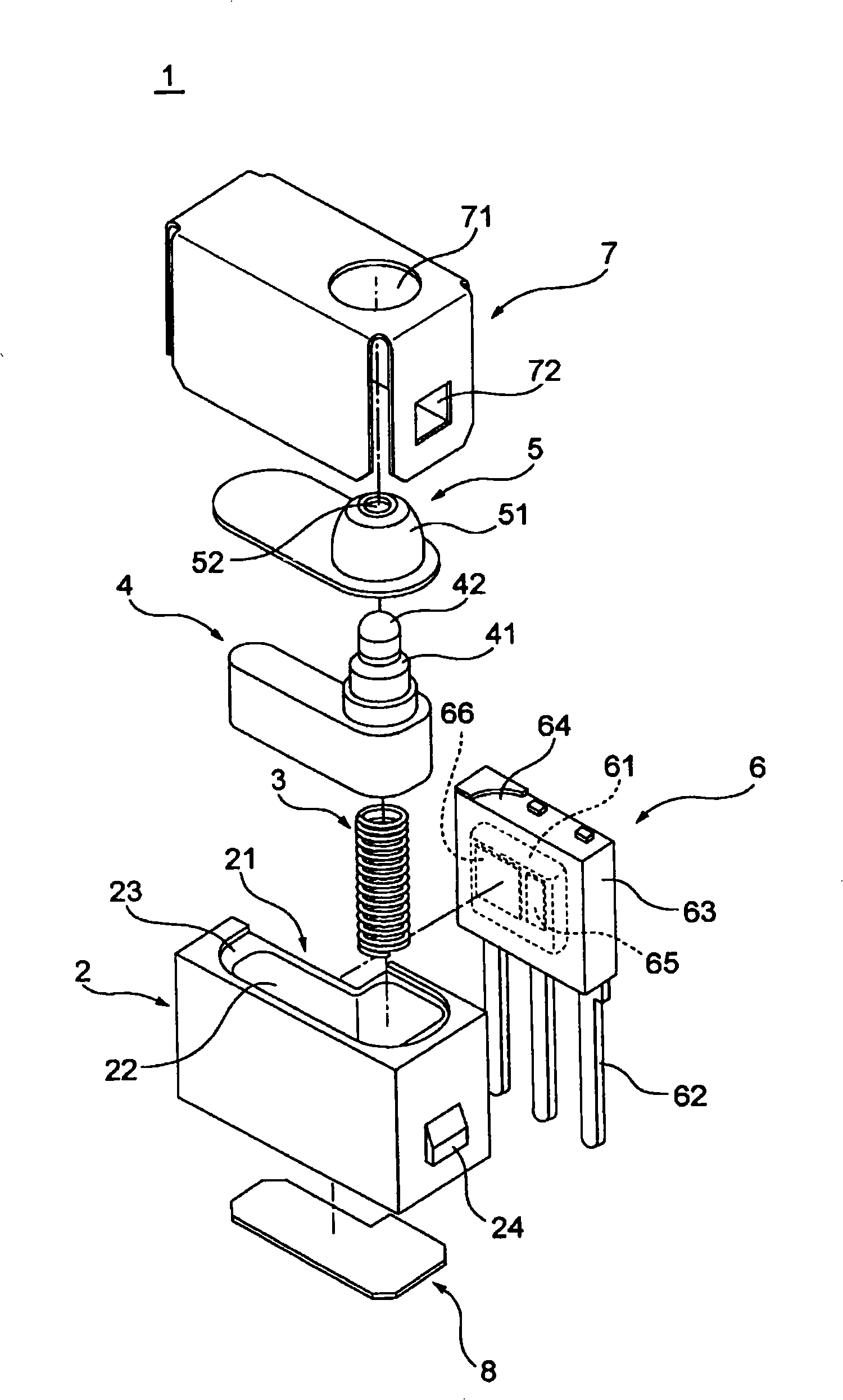

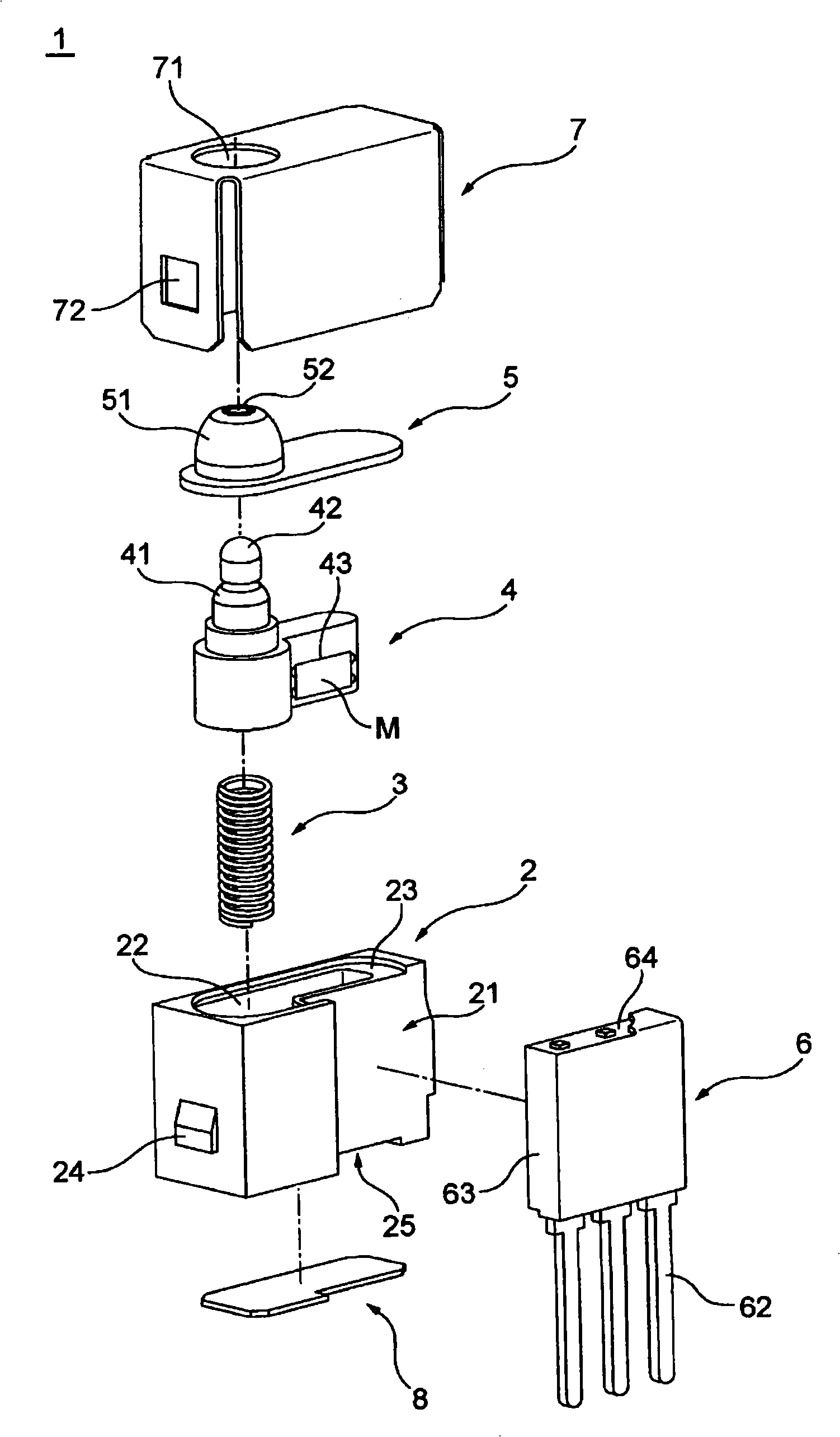

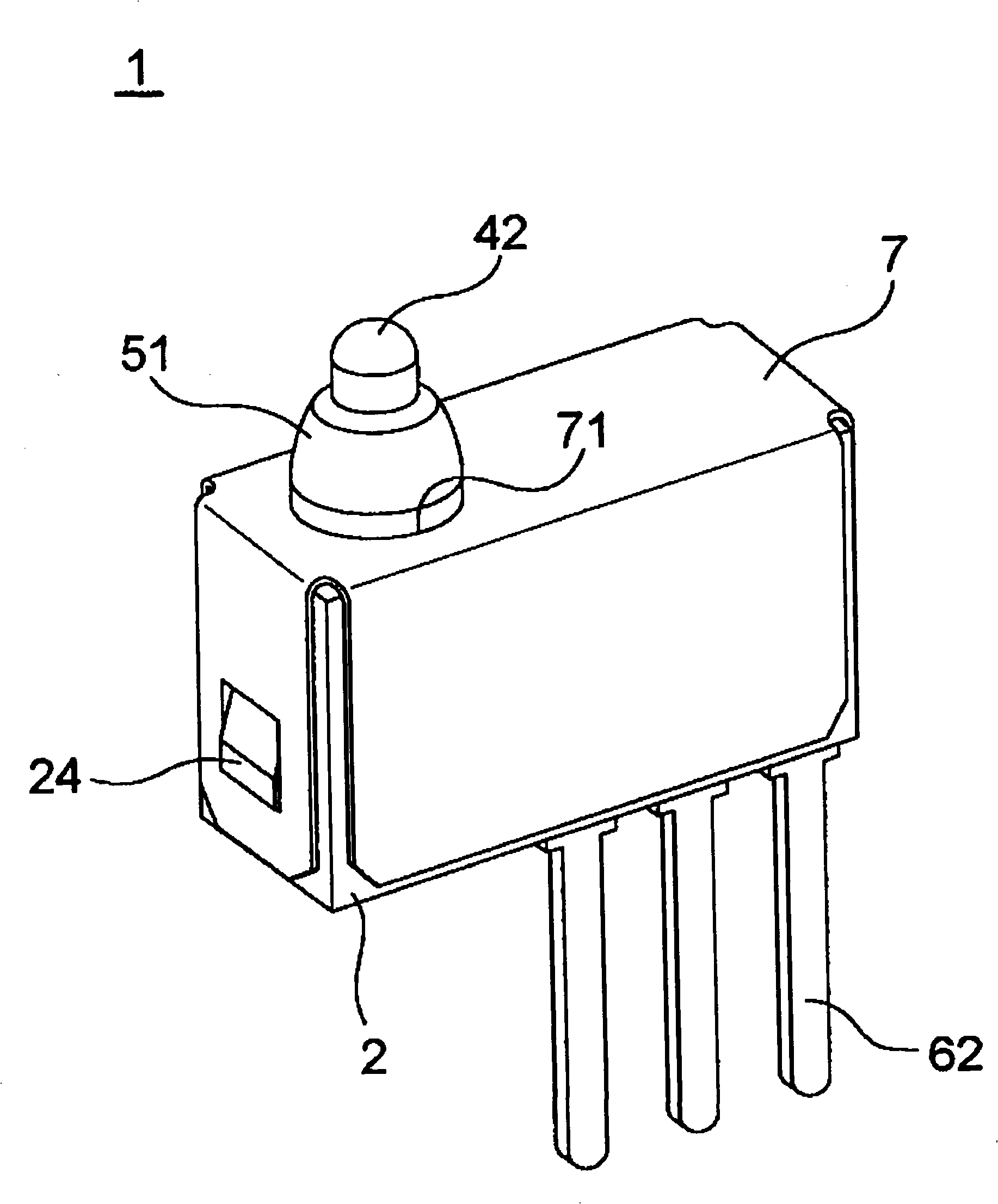

[0031] figure 1 and figure 2 It is an exploded perspective view of the proximity switch device according to the embodiment of the present invention. image 3 It is a perspective view showing the appearance of the proximity switch device of this embodiment. and also, figure 1 and figure 2 The proximity switch device of this embodiment is shown from the opposite sides, respectively.

[0032] like figure 1 and figure 2 As shown, the non-contact switch device 1 of this embodiment includes a housing 2, a compression spring 3 and a slider 4 housed in the housing 2, and a rubber cover 5 placed on the slider 4 housed in the housing 2. , the sensor unit 6 mounted on the housing 2 , the first cover member 7 covering the housing 2 on which the sensor unit 6 is mounted, and the second cover member 8 disposed below the housing 2 while accommodating these compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com