Organic thin film transistor

An organic thin film and transistor technology, applied in the field of organic thin film transistors, can solve problems such as limitations in productivity improvement, and achieve the effects of small performance degradation, excellent heat resistance, and excellent carrier mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

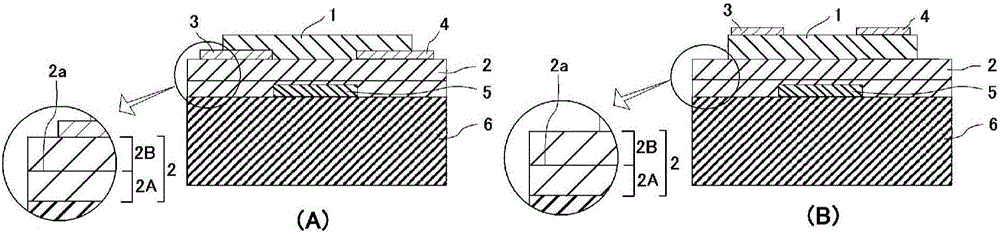

[0344] [Manufacturing Example 1] Fabrication of Bottom Gate OTFT-1

[0345]

[0346] make figure 1 (A) Bottom-gate-bottom-contact OTFT of the form shown. As the substrate 6, a glass substrate with a thickness of 1.1 mm was used, and an ITO film with a thickness of 70 nm was formed thereon to form a gate electrode. A polyimide-based alignment film solution (SE-130, polyimide precursor solution, manufactured by Nissan Chemical Co. ), dried at 100°C for 10 minutes. Then, imidization was performed at 230° C. for 2 hours, whereby a polyimide film (thickness from the first insulating layer side surface of the gate electrode: 100 nm) was obtained. The surface of the film was subjected to rubbing treatment (orientation treatment) using a cotton cloth to form a first gate insulating layer.

[0347]

[0348]The polymerizable liquid crystal compound (liquid crystal monomer) shown in the table below and the polymerization initiator shown in the table below were dissolved in methyl...

manufacture example 2

[0377] [Manufacturing Example 2] Fabrication of Bottom Gate OTFT-2

[0378] On a glass substrate with a thickness of 1.1 mm, a polyimide-based alignment film solution (SE-130, polyimide precursor solution, Nissan Chemical Co. Manufacture), dried at 100°C for 10 minutes. Then, imidization was performed at 230° C. for 2 hours to form a polyimide film (thickness: 100 nm). The surface of the polyimide film was subjected to rubbing treatment (orientation treatment) using a cotton cloth, and an ITO film having a thickness of 70 nm was formed as a gate electrode on a part of the rubbing-treated surface. Then, a second gate insulating layer is formed to cover the gate electrode in the same manner as the formation of X1 described above.

[0379] On the second gate insulating layer, a source electrode, a drain electrode, and an organic semiconductor layer were formed in the same manner as in Manufacturing Example 1 to obtain an OTFT. The obtained OTFT is called OTFT Zt1.

manufacture example 3

[0380] [Manufacturing Example 3] Fabrication of Bottom Gate OTFT-3

[0381] In the above-mentioned Production Example 1, the following polymer liquid crystal compound (weight average molecular weight: 9300) having a repeating unit was used instead of the liquid crystal monomer, and alignment aging was carried out at 80°C, and the polymerization reaction was carried out by ultraviolet irradiation , except that the OTFT was produced in the same manner as in Production Example 1. The following polymer liquid crystal compounds exhibit a nematic phase at 60 to 90°C.

[0382] [chem 33]

[0383] polymer liquid crystal compound

[0384]

[0385] The obtained OTFT is called OTFT Zt2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com