Pipeline for the hydraulic or pneumatic transport of solids

A technology for pipes and solids, applied in the field of pipes used for hydraulic or pneumatic conveying of solids, can solve the problems of wear and large deviation of the wall thickness of the wear ring, and achieve the effect of long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

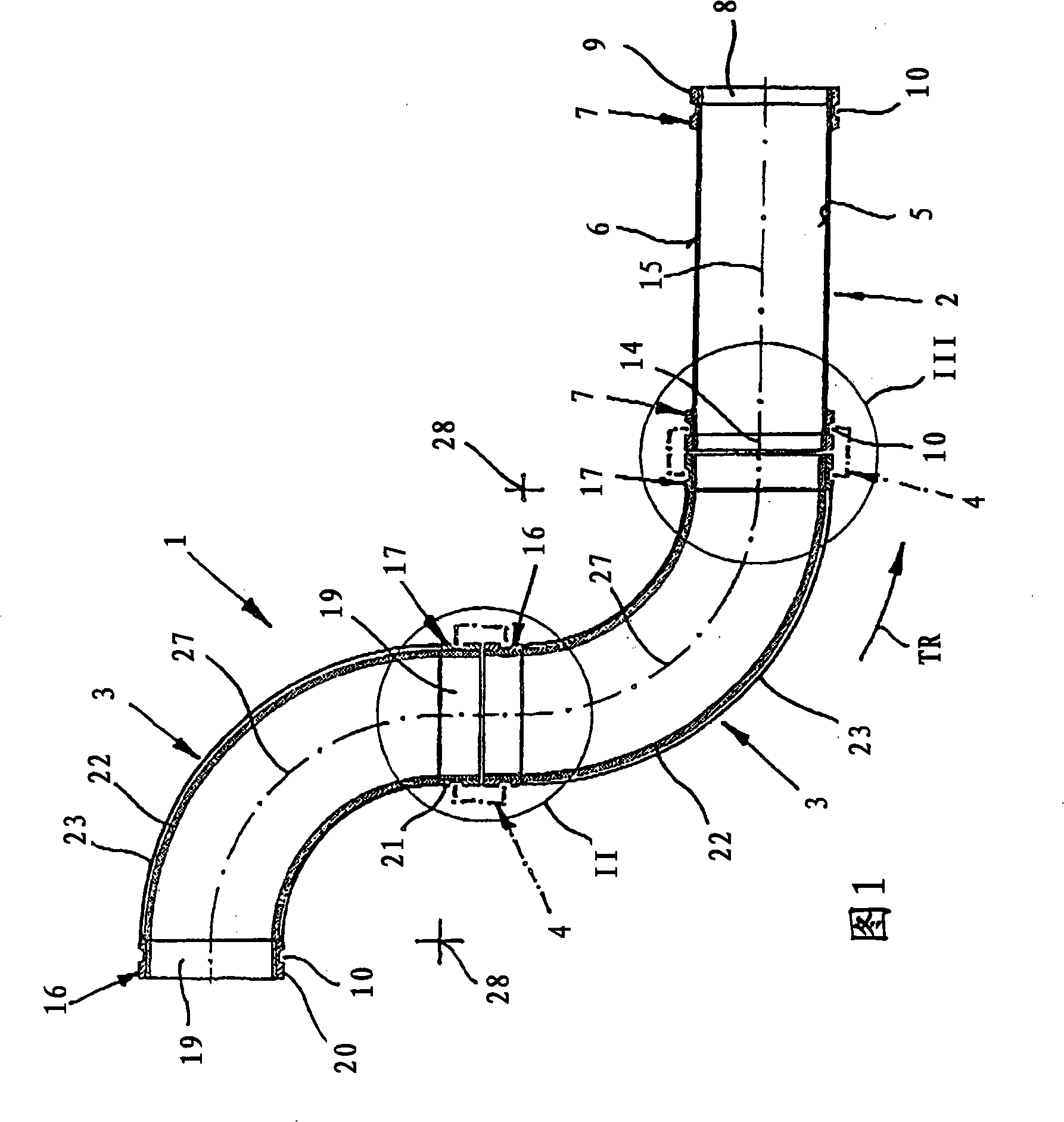

[0027] In FIG. 1 , a longitudinal section of a pipeline for hydraulically or pneumatically conveying solids, such as concrete, is designated by 1 . Such a pipe 1 finds practical use, for example in connection with a truck-mounted concrete pump, as a concrete distribution boom which can be turned over together. The pipeline 1 has a predetermined conveying direction, which is indicated by the arrow TR.

[0028] A pipe 1 with a length of up to more than 60 meters consists of a straight pipe piece 2 and an elbow 3 with a 90° bend, the contour of which allows two elbows 3 following each other, or one elbow 3 And a pipe 2 which is not only connected by means of a shell coupling 4 which is only schematically depicted, but which also allows relative rotation of the pipe 2 and the elbow 3 within the shell coupling 4 . The long pipe 1 is folded in such a way that it can be moved from one installation position to another on a movable pipe base.

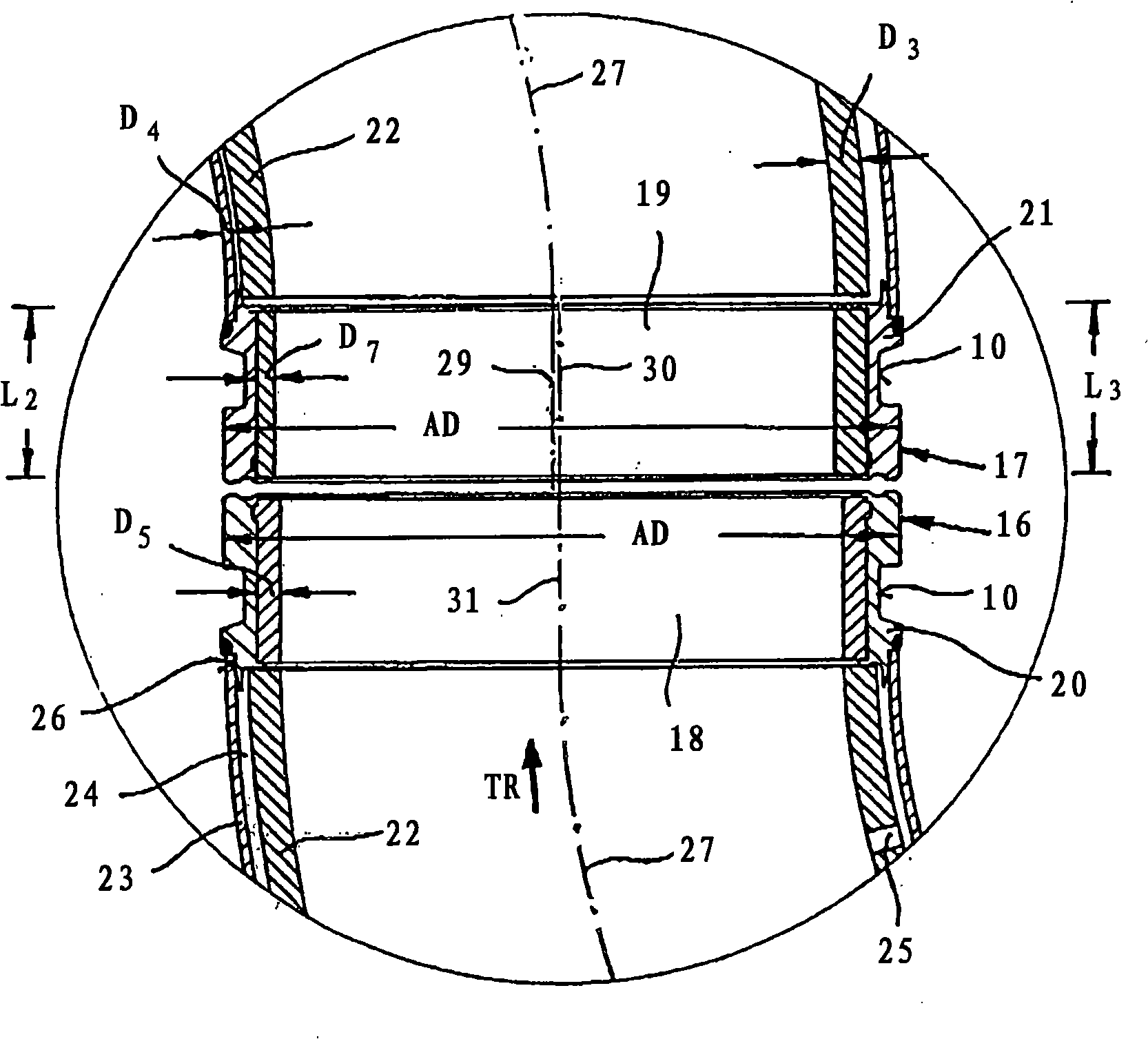

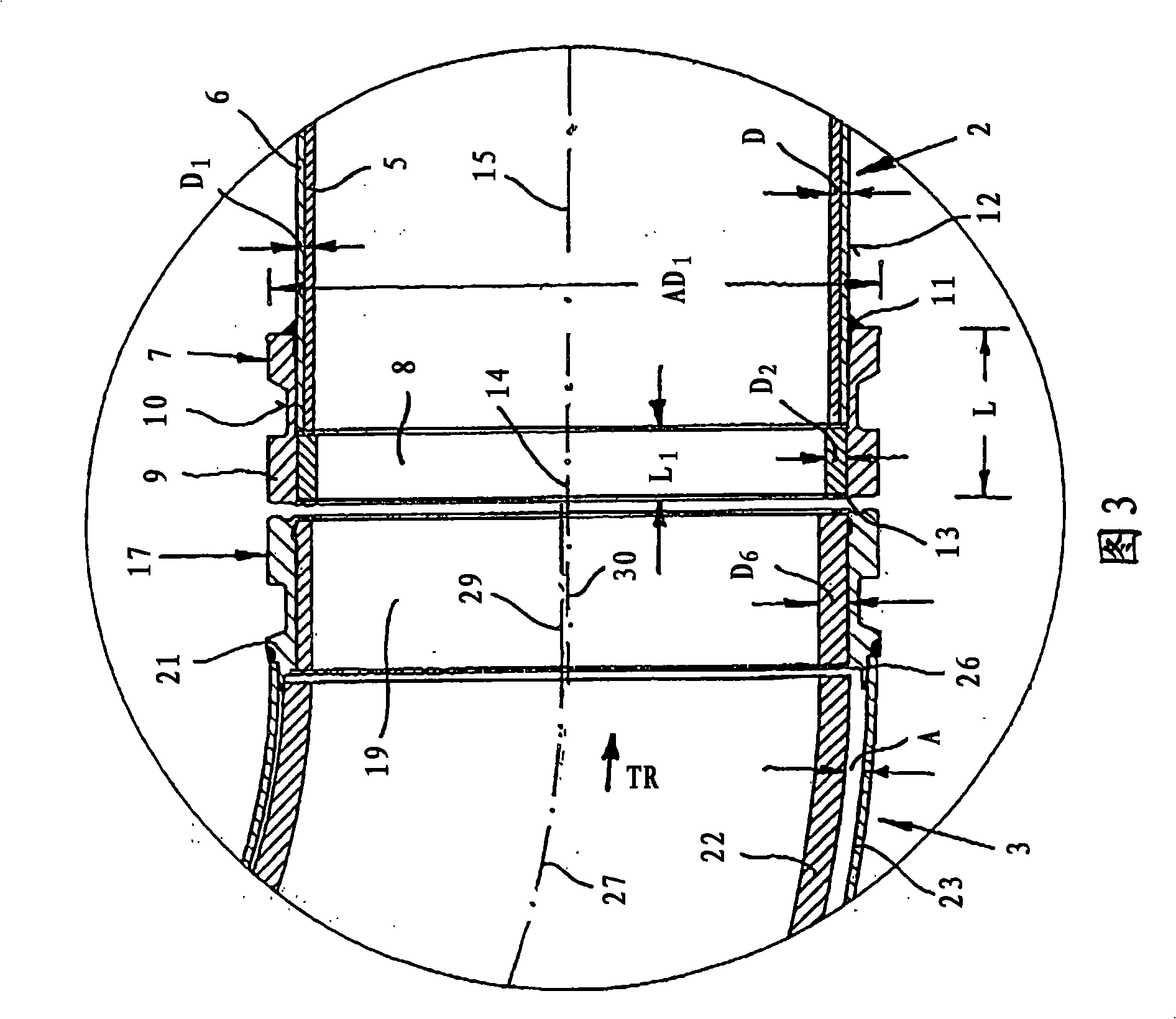

[0029] The pipe part 2 (see FIGS. 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com