Turnover frame of refuse compressor

A garbage compression and drum pressing technology, which is applied in the field of tipping frames, can solve problems such as unsatisfactory working of the tipping frame, easy failure of the connecting rod mechanism, and reduced work efficiency, etc., to achieve light weight, simple structure, compact and solid structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

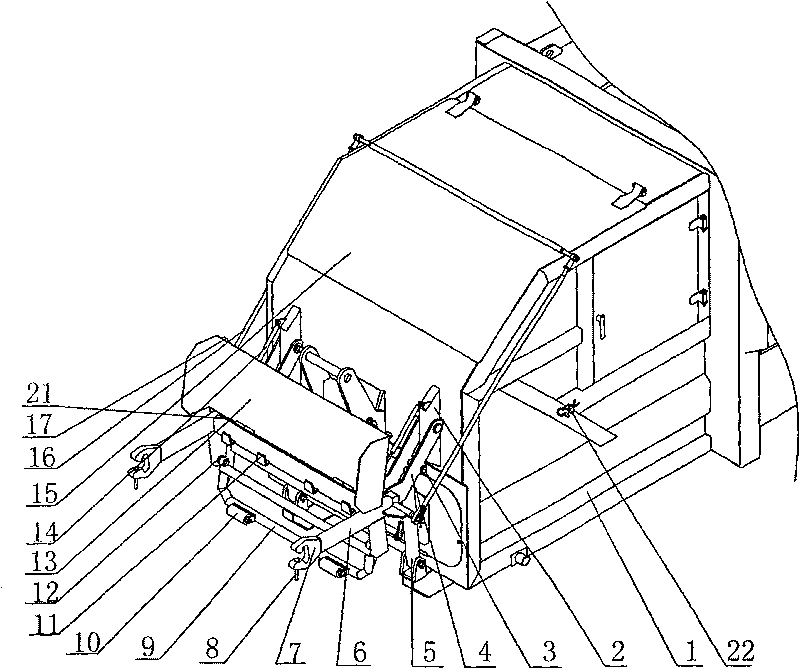

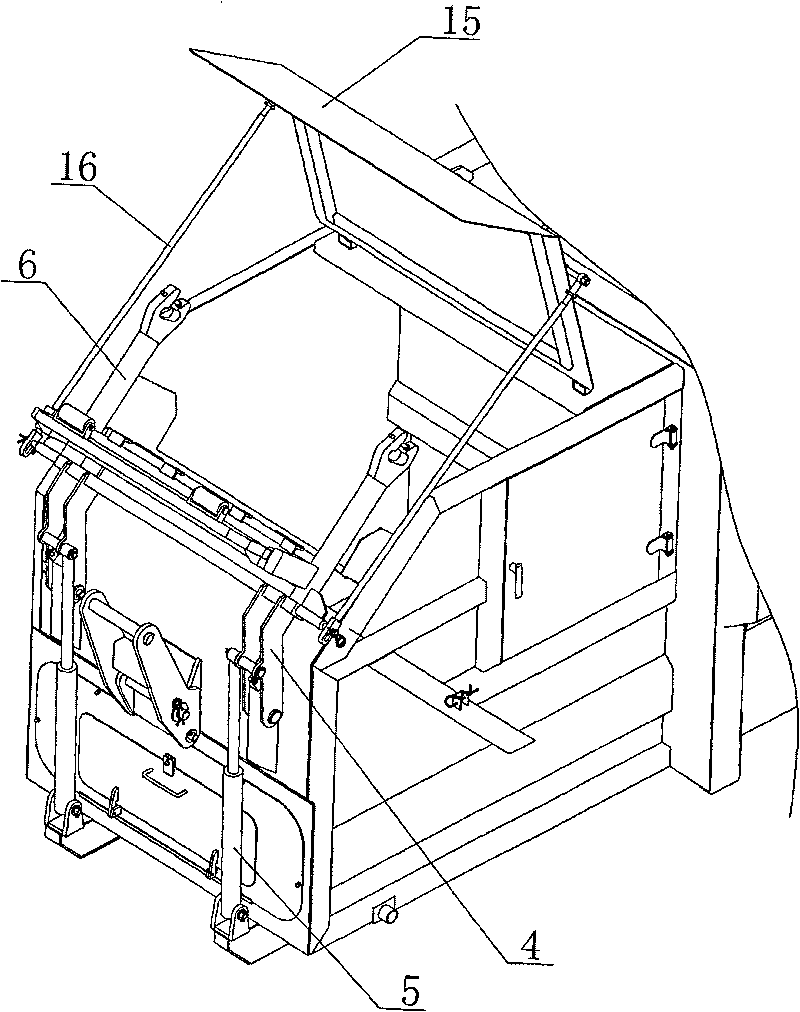

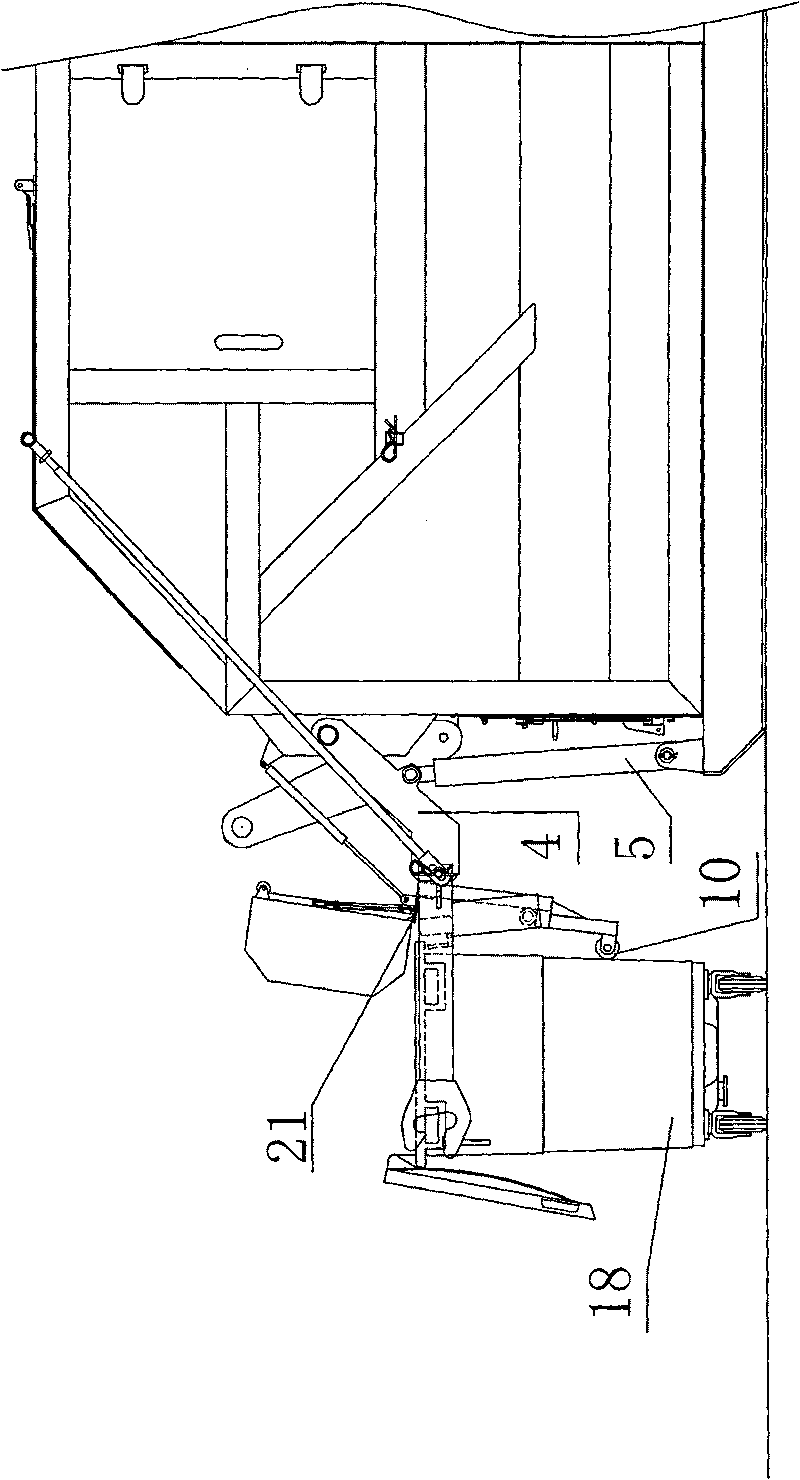

[0018] see figure 1 , figure 2 ,and Figure 6 , this embodiment includes hydraulic cylinders 5 installed on both sides of the front of the garbage compressor head box body 1, two rotating main arms 4 that can rotate up and down on the support base 2 hinged on the box body 1, and the hydraulic cylinder 5 The retractable piston rod end is connected to the rotating main arm 4 through the oil cylinder pin shaft 3, and a hook assembly 6 is fixedly connected between the two rotating main arms 4. The hook assembly 6 includes upward hooks 11, and these hooks 11 are corresponding to various The upper edge of the international standard garbage can is provided with grooves on the outside, and the front ends of both sides of the hook assembly 6 are also provided with a "U"-shaped bucket shaft hook 7 with an opening forward, which is used to articulate with the support shaft on the garbage can. The inside of the bucket shaft hook 7 is provided with a slideway with a certain angle and le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com